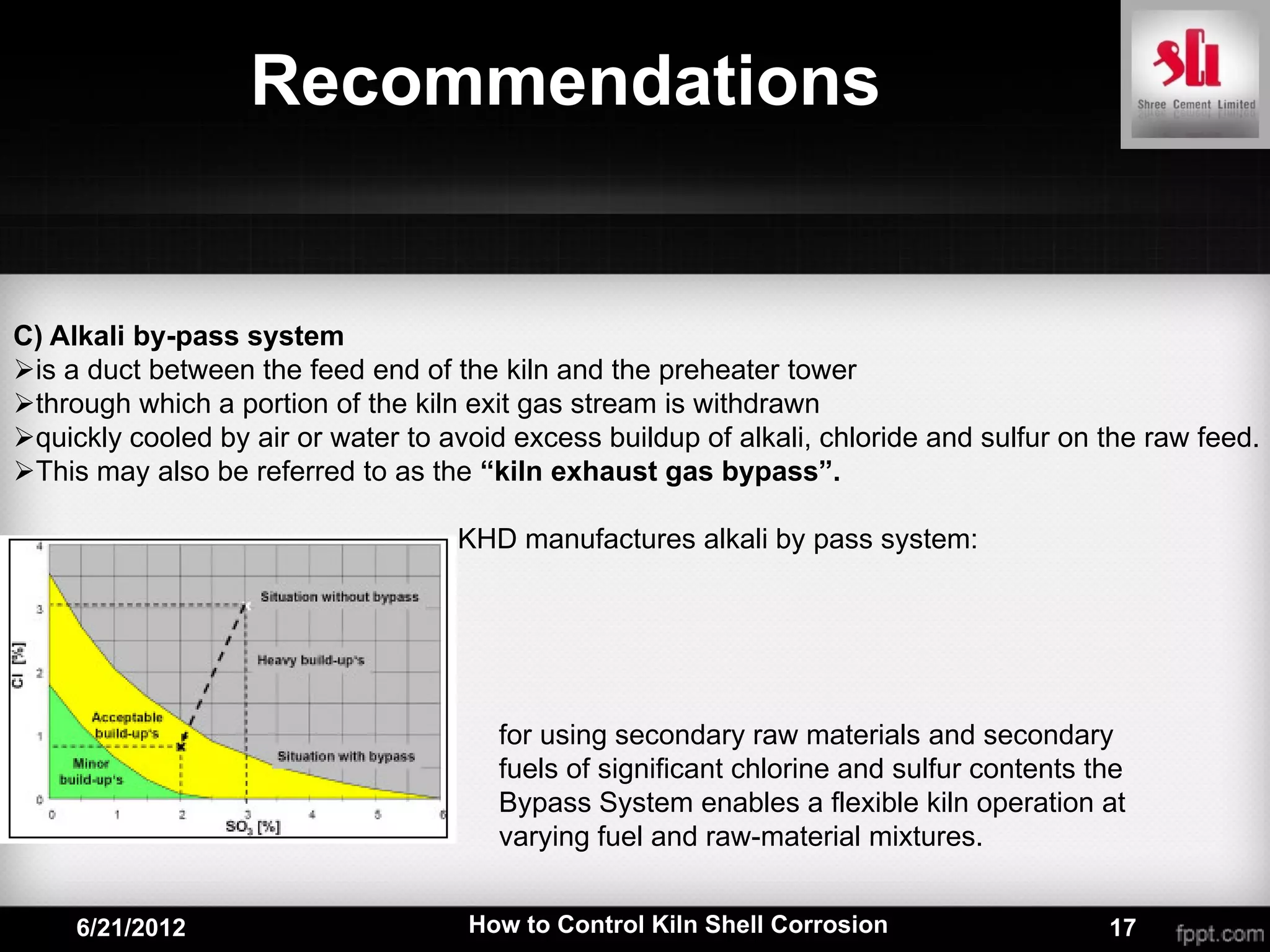

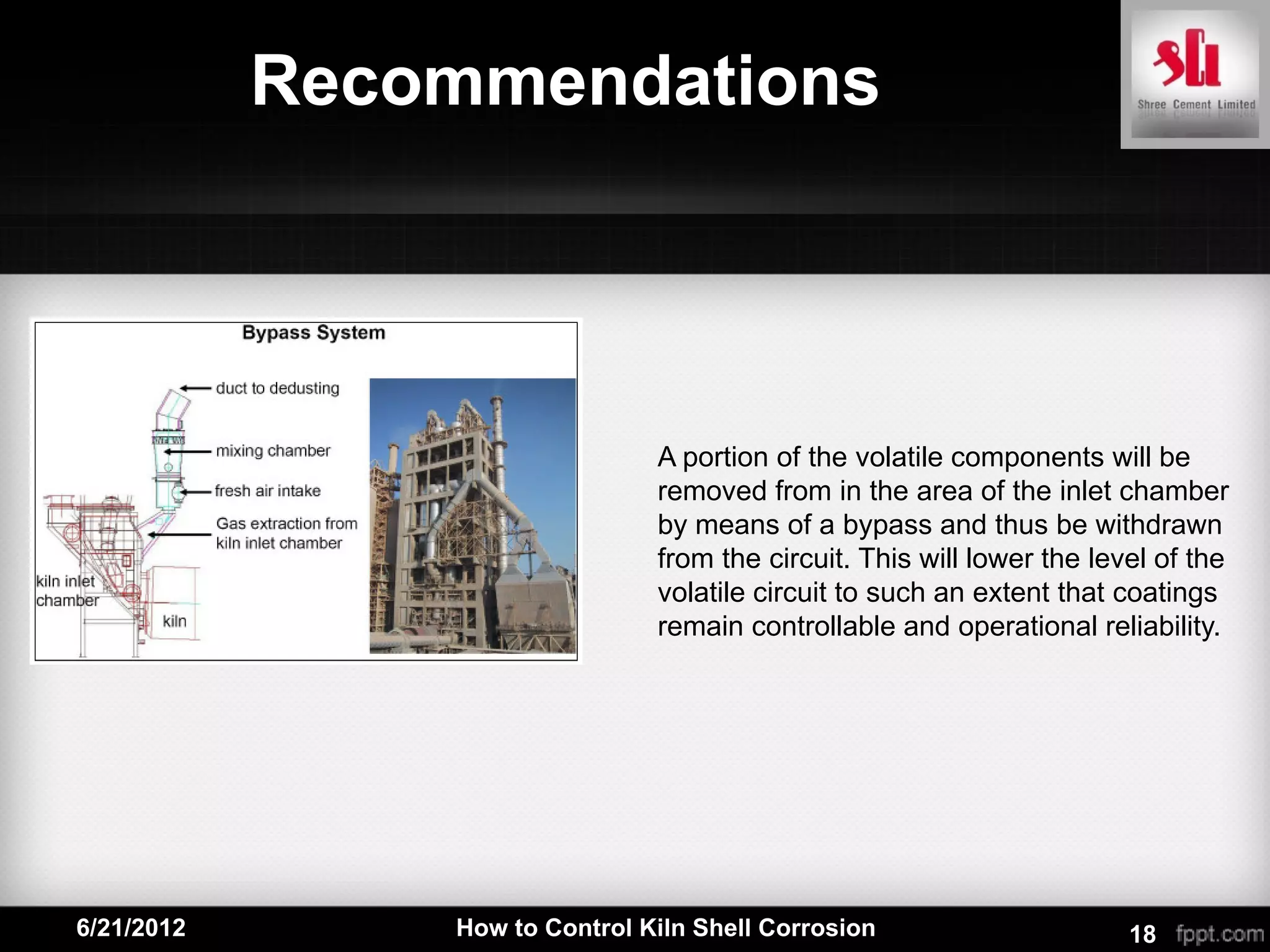

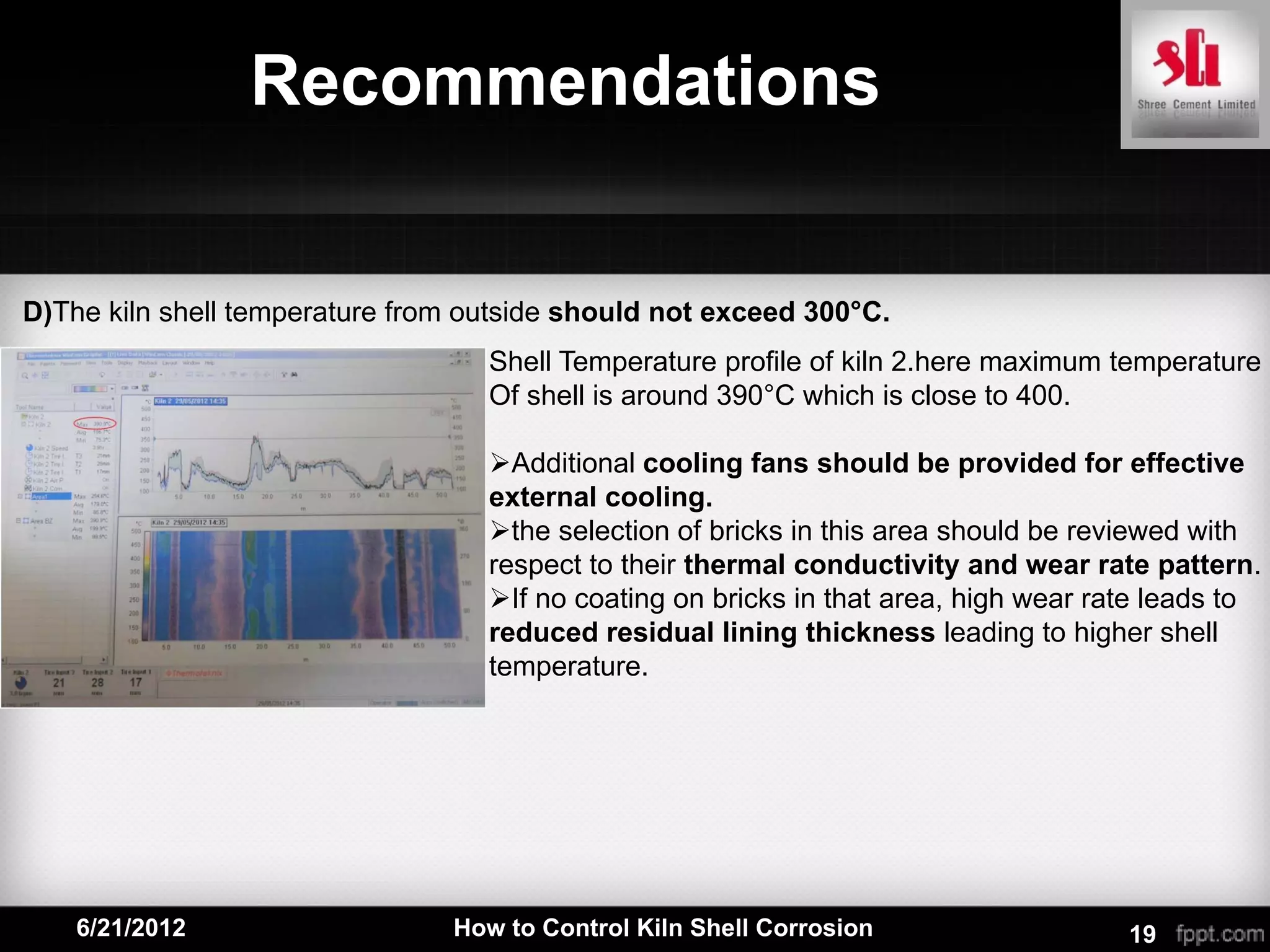

The document discusses how to control corrosion of cement kiln shells. It describes how volatile compounds from alternative fuels can cause corrosion by penetrating refractory lining and reaching the shell. Proper refractory selection, installation, and oxidizing kiln conditions can minimize corrosion. The mechanisms of oxidation and sulfidization corrosion are explained. Maintaining good refractory quality with low porosity, proper installation, and controlled process parameters can help reduce shell corrosion.