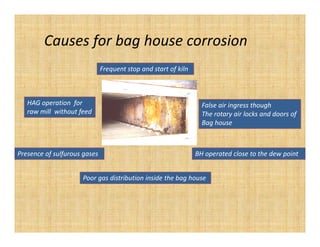

The document discusses corrosion in kiln and raw mill bag houses. It identifies several causes of corrosion including frequent kiln start/stops, raw mill operation without feed, and bag house operation close to the dew point. This allows condensation which, combined with acidic gases like SO2, leads to corrosion. Strategies to reduce corrosion include keeping bag houses hot to prevent condensation, minimizing acid gases by routing kiln exhaust through raw mills, and ensuring proper insulation of bag houses.