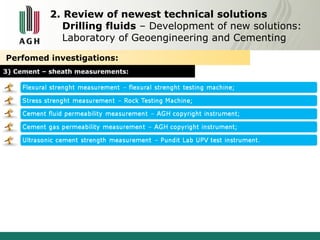

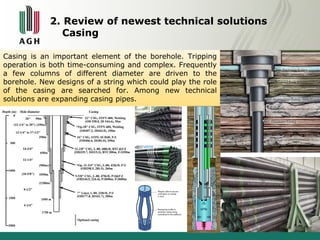

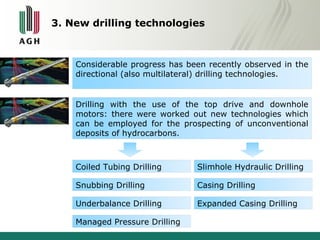

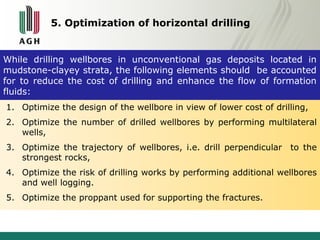

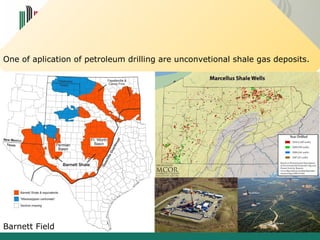

1. The document discusses developments in drilling technologies for shale gas, focusing on new technical solutions for rigs, strings, bits, drilling fluids, and casing.

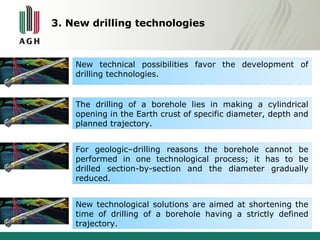

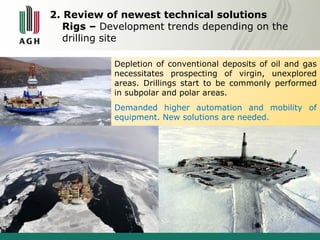

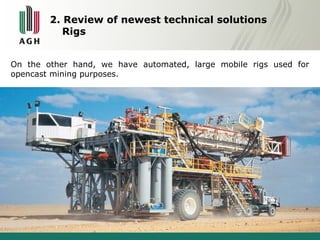

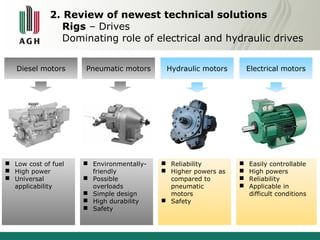

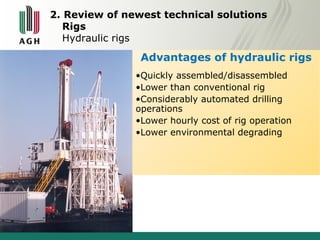

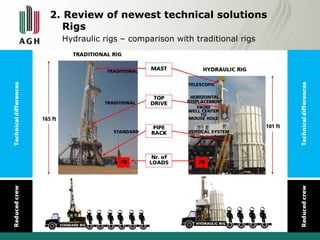

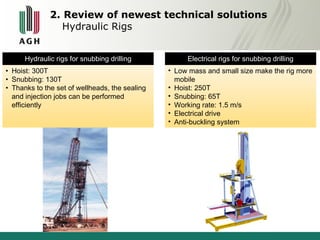

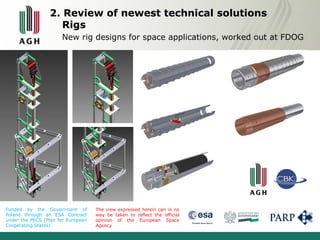

2. It describes trends toward more automated, mobile rigs suited for difficult terrain as well as offshore rigs. New rig designs are being developed for space applications.

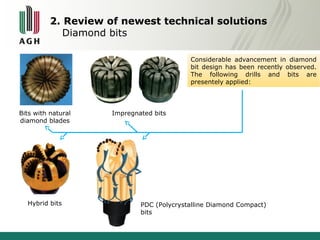

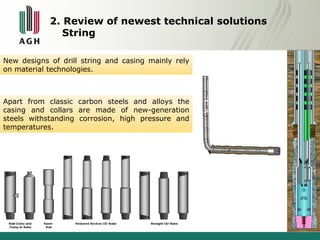

3. Improvements in strings include new materials like titanium alloys to withstand high pressures and temperatures. Developments in bits include sealed bearings and optimized designs for different rock hardness.

![2. Review of newest technical solutions

„String”

Drill string can be also made of titanium or various aluminium alloys. Casing, used for

protecting borehole against crushing or contracting rocks used to be made only of

steel; now it is produced also of other materials.

Comparison of properties of mud pipes made of titanium (Ti- 6A1- 4V) and

standard casing (27/8-in. x 0.362 )

Average unit

mass

[lb/ft]

Young modulus

[psi]

Maximum

torsional

moment ,

[ft . lb]

Tensile

strength, [lb]

Minimum yield

Material point Re [psi]

S-135 Steel 135 000 385,820 20 798 30 000 000 10.50

G-105 Steel 105 000 300,082 16 176 30 000 000 10.50

Ti-6A1-4V 120 000 342,951 18 487 17 000 000 6.19](https://image.slidesharecdn.com/horizon2020-141122091817-conversion-gate02/85/Horizon-2020-27-320.jpg)