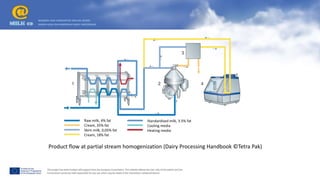

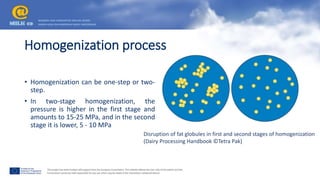

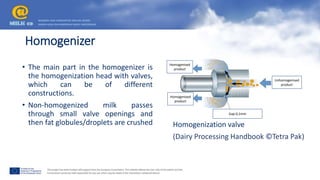

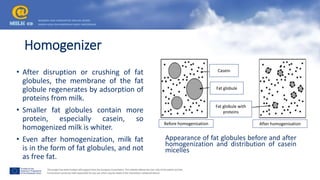

The document discusses homogenization, which is an industrial process that reduces the diameter of fat globules in milk and cream using high pressure. This increases the stability of the milk fat emulsion and prevents fat separation. Homogenization breaks down fat globules into sizes less than 2 micrometers. It is commonly used in pasteurized and sterilized drinking milks to prevent fat separation and give a richer taste and viscosity. However, homogenization is not recommended for cheese production as it disrupts the technological properties of milk.