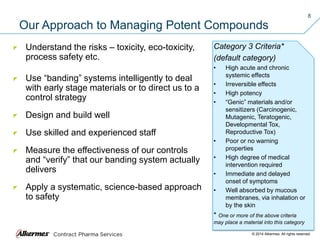

Alkermes Contract Pharma Services specializes in solid oral dosage and sterile fill finish manufacturing, boasting over 40 years of experience and a client roster that includes seven of the world's top ten pharmaceutical companies. Their Athlone, Ireland facility is equipped to handle highly potent compounds and has the capacity to produce 2 billion solid oral dosages annually, employing rigorous safety and risk management practices. The company emphasizes operational excellence through Lean Six Sigma initiatives, ensuring compliance with global regulatory standards while addressing the challenges of high potency manufacturing.