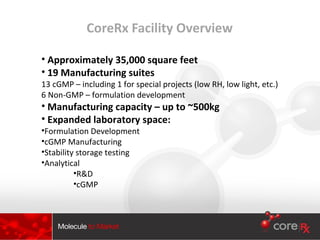

CoreRx is a dosage form development company specializing in formulation development, analytical development, and clinical manufacturing. They focus on client satisfaction, quality science, strong communication, timeline management, and client goals. CoreRx offers preformulation, formulation development, analytical services, manufacturing, packaging, labeling, and stability services. They have experienced scientific staff and capabilities including specialized dosage forms. CoreRx aims to get clients' products to market quickly while maintaining compliance.