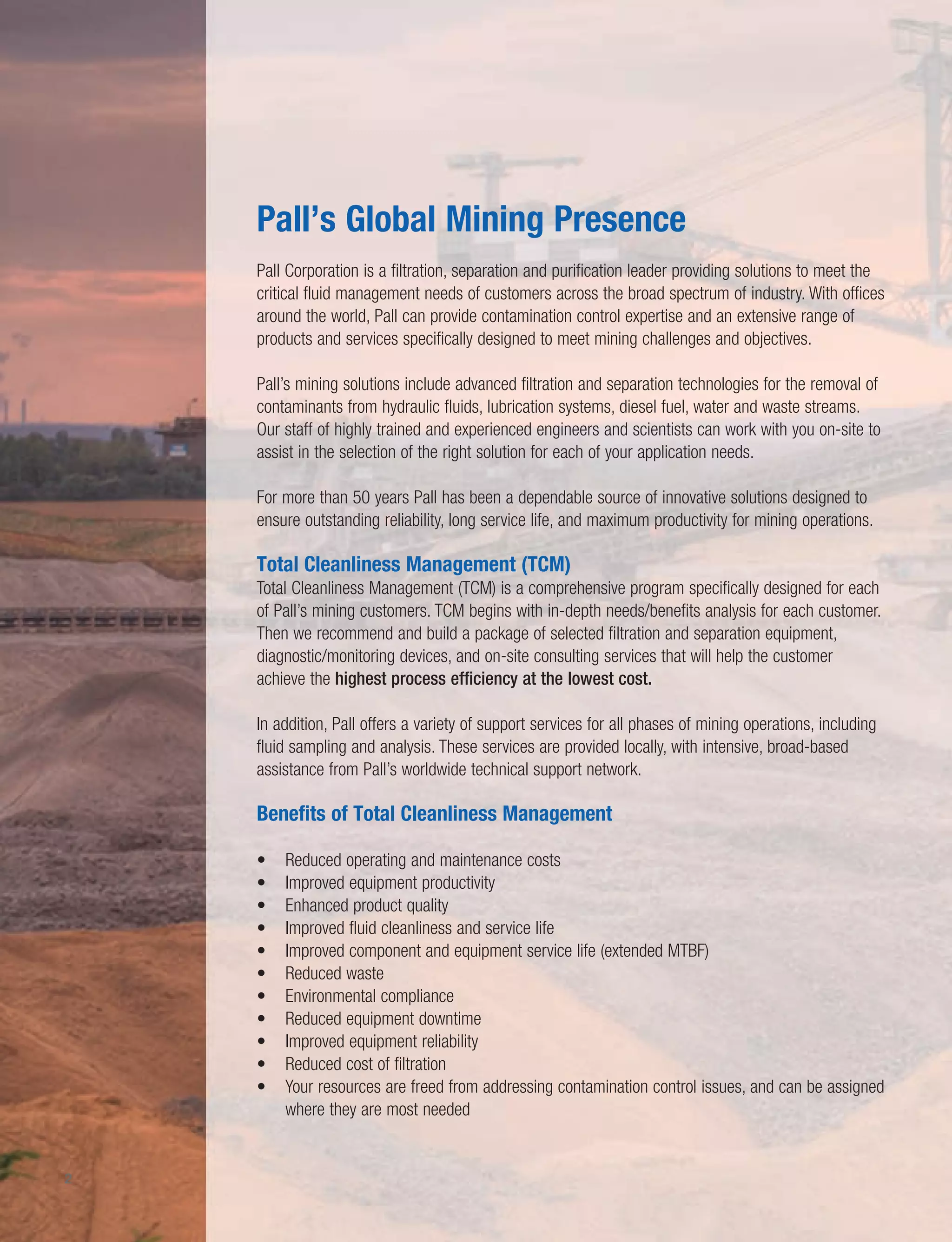

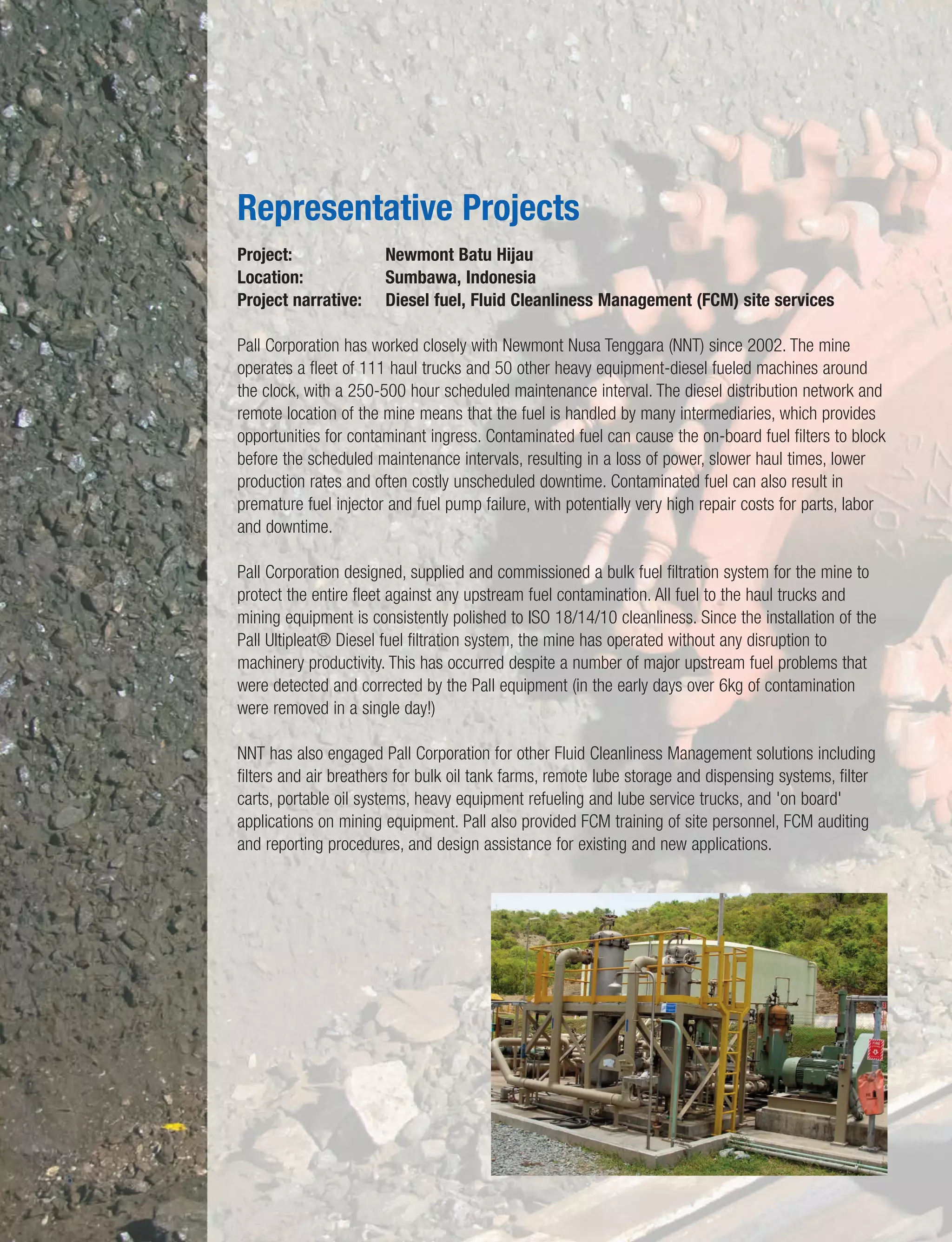

Pall Corporation is a global filtration, separation and purification company that provides solutions for critical fluid management needs across industries, including mining. The document discusses Pall's experience working with various mining customers around the world to implement filtration and separation technologies for hydraulic fluids, lubricants, diesel fuel, water and waste streams. It highlights several representative projects Pall has completed for mining customers involving applications such as diesel fuel filtration, crusher lubrication systems, hydraulic systems, and water treatment.