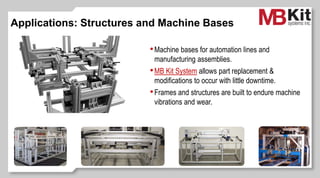

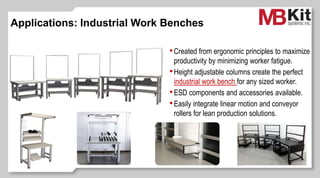

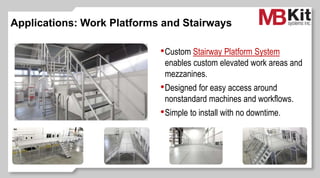

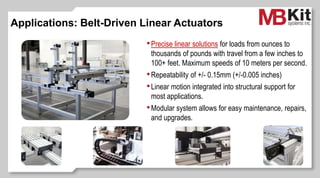

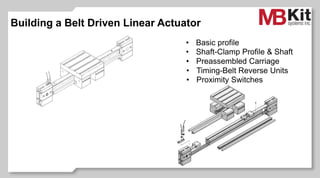

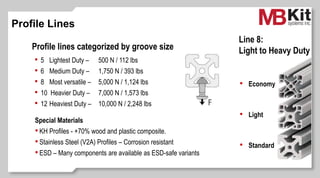

MB Kit Systems provides custom mechanical solutions including linear actuators, material handling systems, and safety guarding for various industrial applications. They offer no-cost engineering services, in-house production, and extensive inventory to ensure fast turnaround and high-quality products. Their modular design allows for easy maintenance and compatibility with other systems, accommodating a wide range of operational demands.