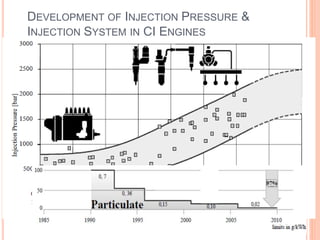

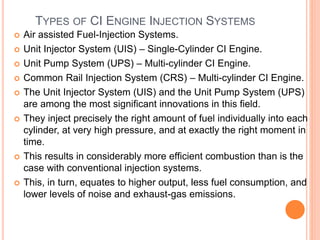

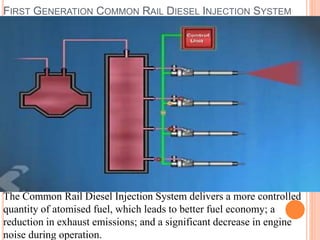

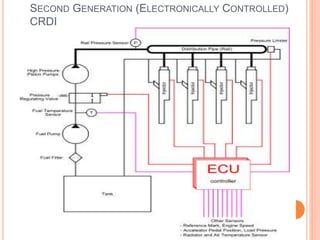

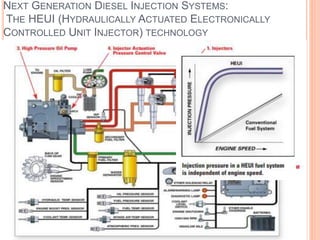

The document discusses various fuel injection systems for CI engines, including air-assisted, unit injector, unit pump, and common rail injection systems, emphasizing their efficiency in combustion and emissions reduction. It outlines the development history of the common rail diesel injection system, starting from its prototype in the 1960s to its implementation in the mid-1990s in production vehicles. The second generation of common rail systems features electronically controlled injectors that optimize parameters for improved performance and fuel economy.