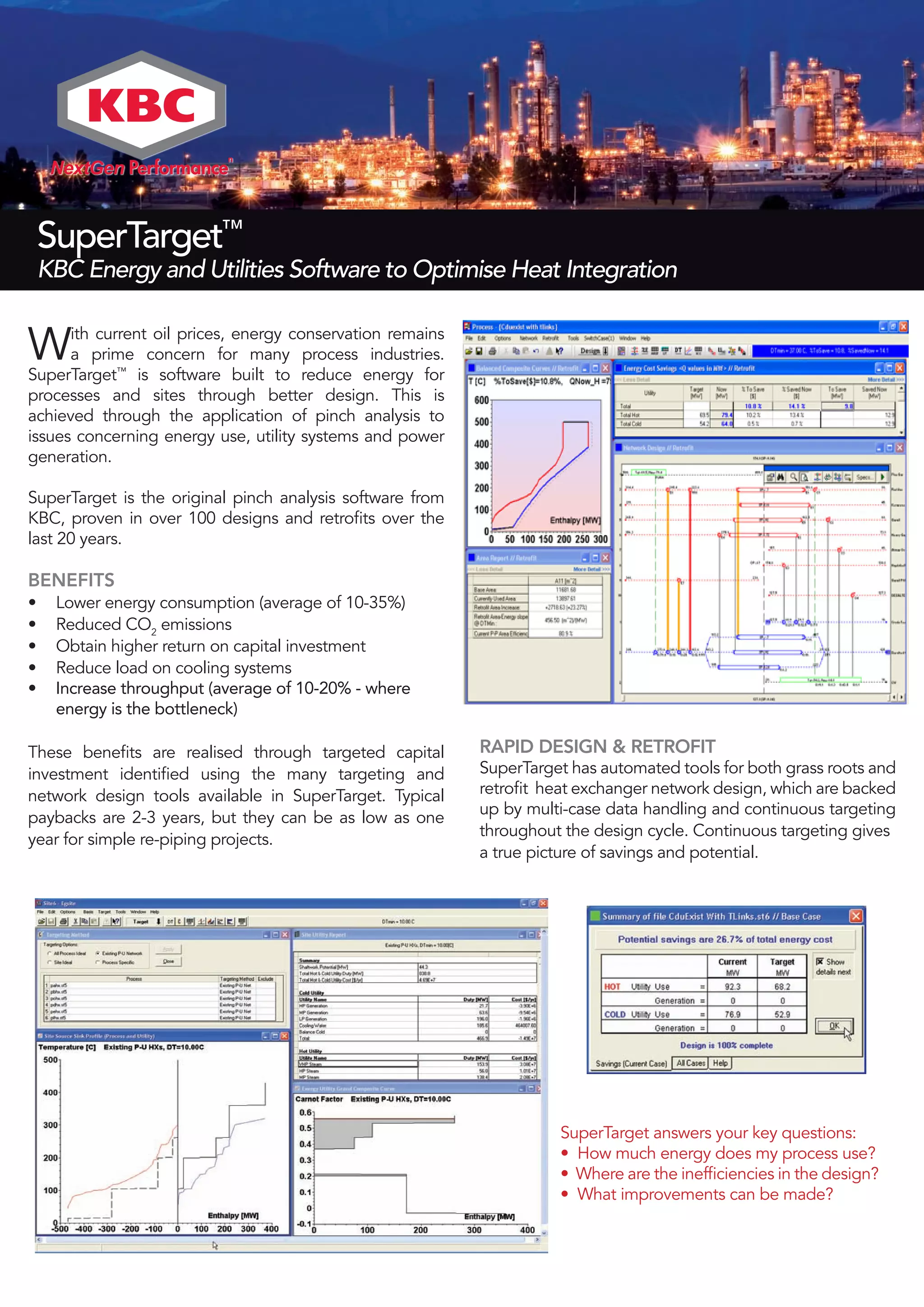

SuperTarget is pinch analysis software from KBC Energy and Utilities that is used to optimize heat integration and reduce energy usage in industrial processes. It can lower energy consumption by 10-35% on average and payback is typically 2-3 years. SuperTarget takes stream data from process simulators to identify inefficiencies and opportunities for improvement through targeting and heat exchanger network design tools.