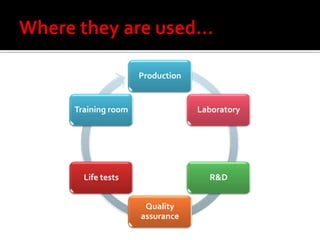

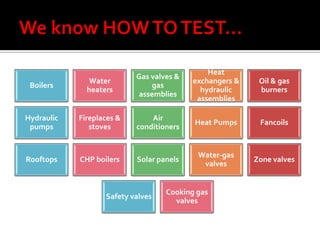

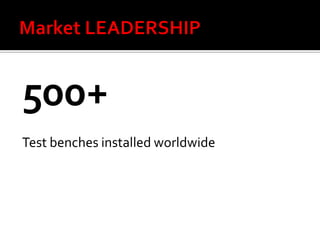

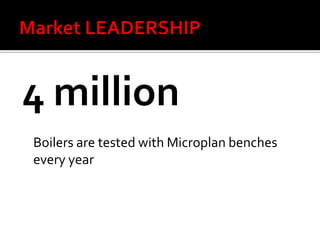

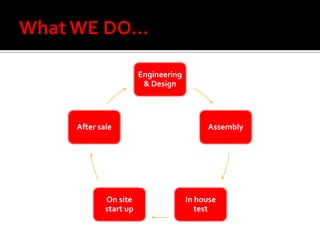

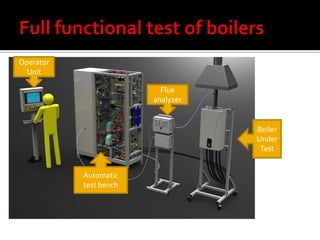

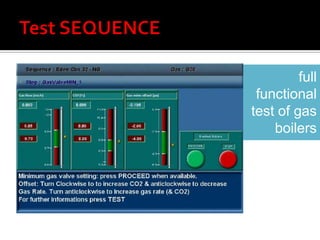

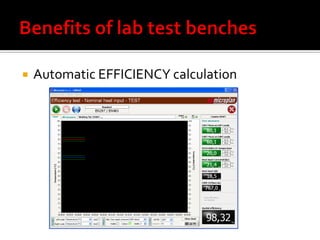

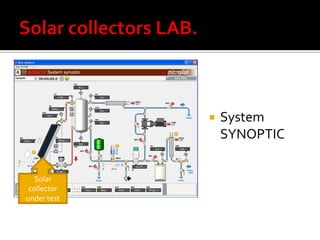

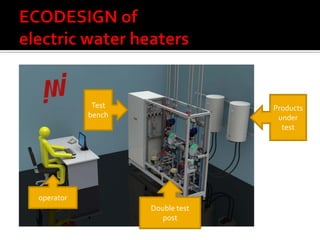

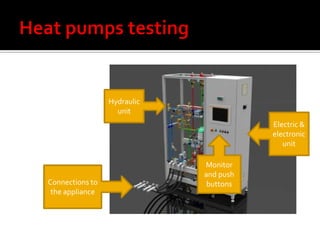

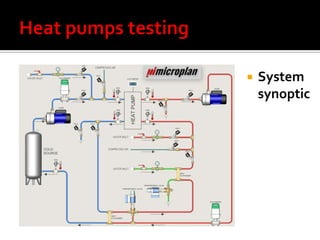

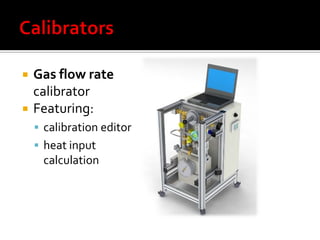

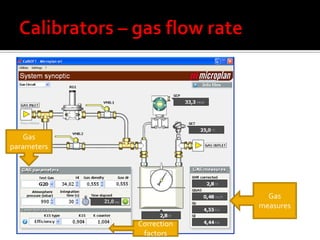

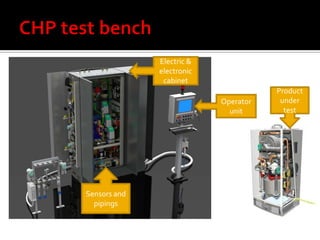

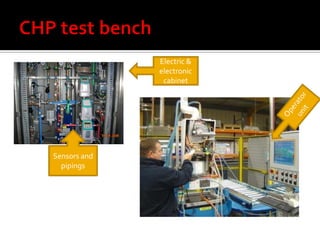

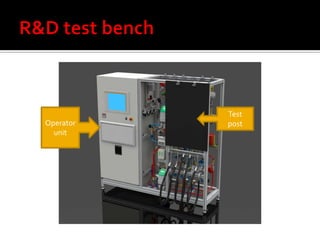

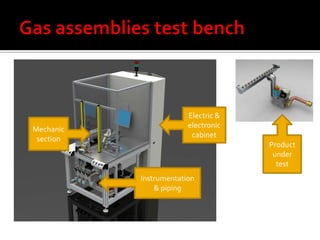

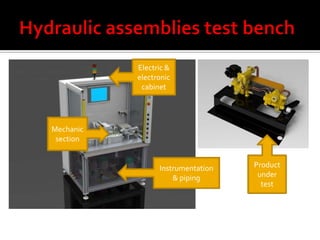

Microplan is an Italian company that designs and manufactures automatic test benches for heating, ventilation, and air conditioning (HVAC) appliances like boilers, heat pumps, and solar panels. They have installed over 500 test benches worldwide and test 4 million boilers per year. Their test benches provide accurate, reliable, and robust testing that improves product quality while reducing testing time and costs. Microplan also offers engineering services, spare parts, training, and technical support.