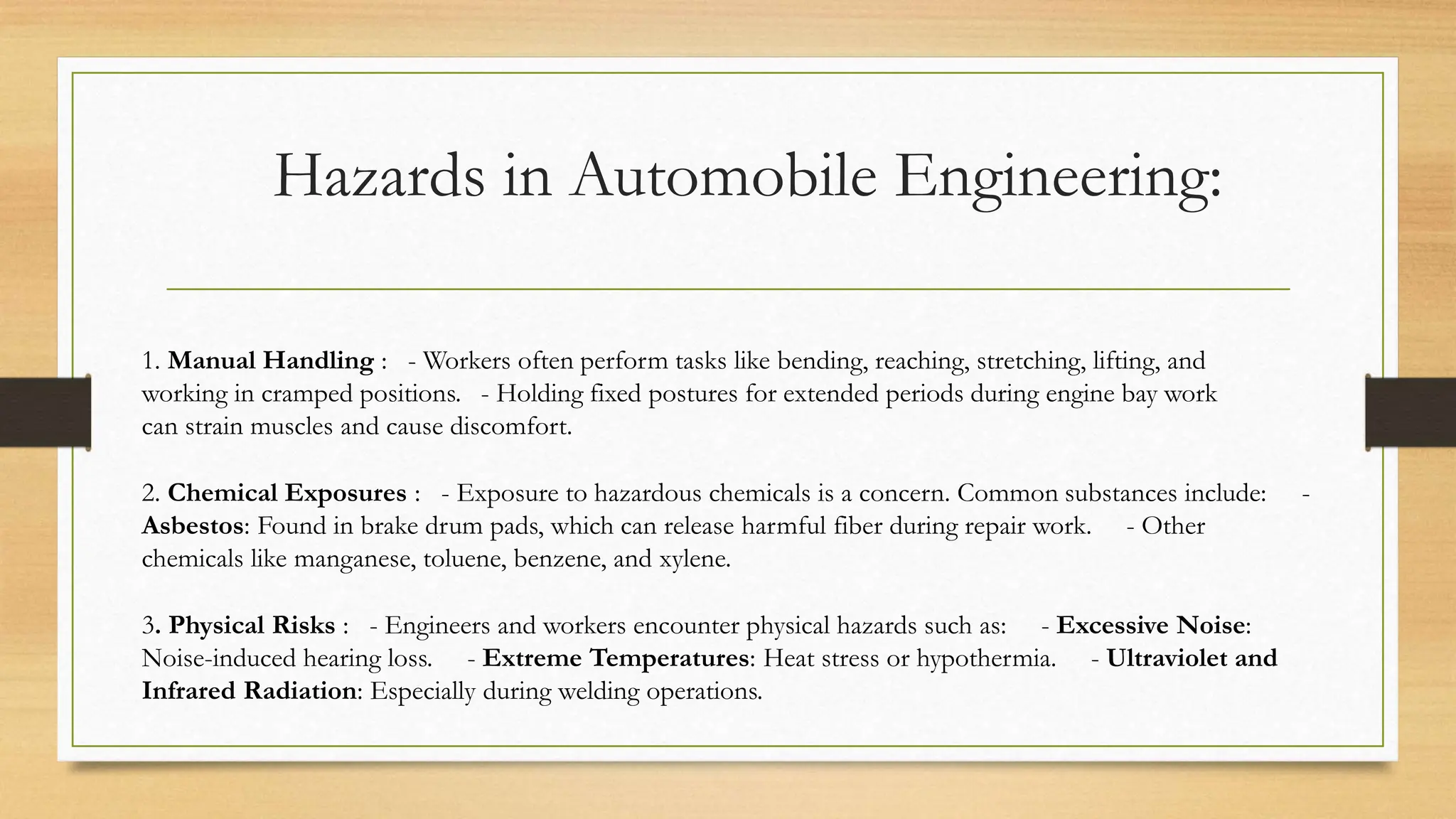

The seminar presentation discusses the importance of hazard analysis in the automotive industry to ensure safety during vehicle manufacturing and operation. It covers various types of hazards including mechanical, electrical, and human factors, along with methods for hazard analysis like FMEA and HARA. The conclusion emphasizes the need for continuous improvement and adherence to safety protocols to mitigate risks and enhance overall vehicle safety.