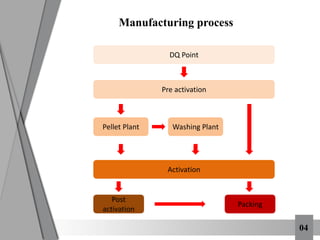

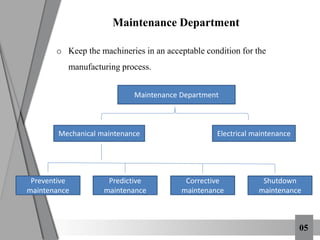

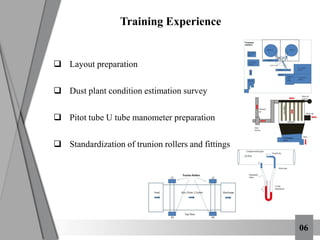

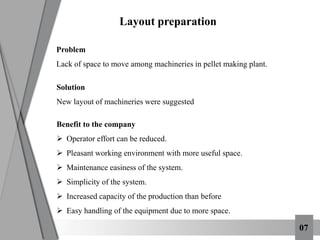

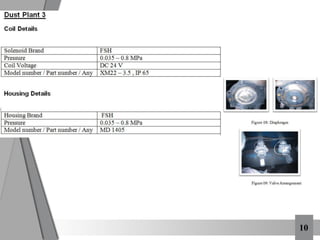

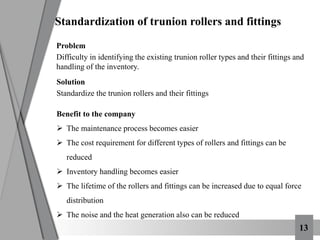

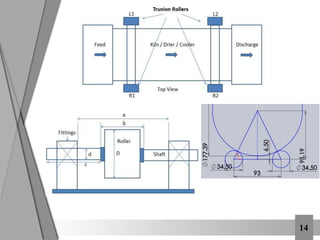

Haycarb PLC is a leading manufacturer of activated carbon from coconut shells with over 35 years of experience. The document summarizes Lakshitha M.A.R's 3-month industrial training at Haycarb, including an introduction to the company's history and production process. As part of the training, Lakshitha conducted various projects in the maintenance department like preparing a new layout to improve efficiency, surveying dust plants to assess maintenance needs, creating an air flow meter to detect leaks, and standardizing roller parts to simplify inventory. The training provided hands-on experience in maintaining equipment and identifying solutions to issues.