This document provides information on grey cast iron materials from Qingdao Casting Quality Industrial Co., Ltd., including:

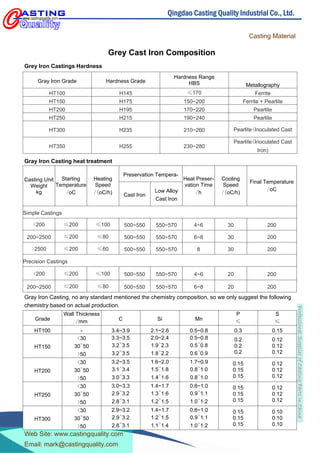

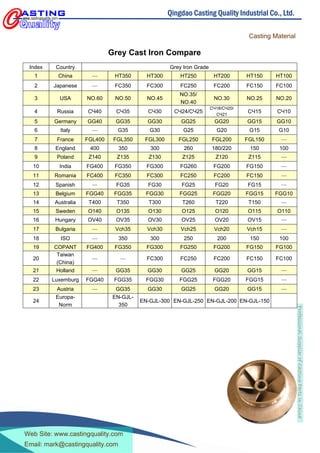

1. Descriptions of the composition, properties, and grades of grey cast iron.

2. Tables listing mechanical properties like tensile strength for different grades and casting thicknesses.

3. Suggested chemical compositions for different grades.

4. Information on heat treatment and how it affects hardness and microstructure.