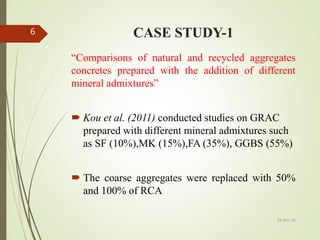

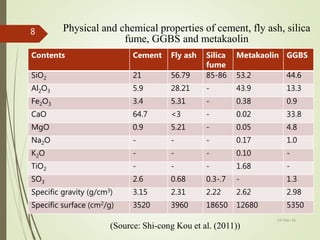

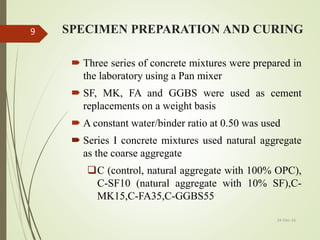

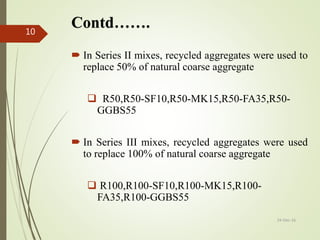

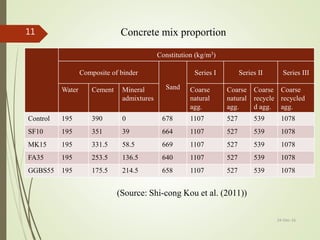

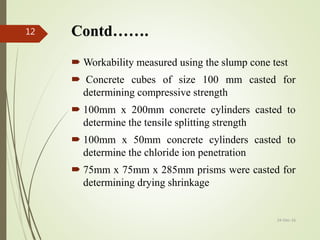

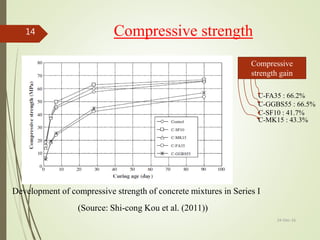

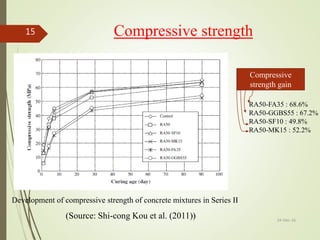

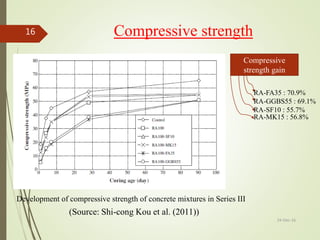

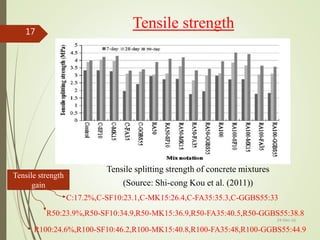

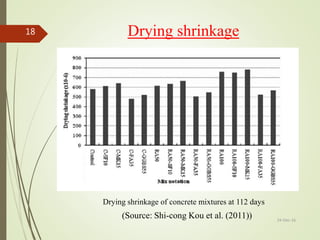

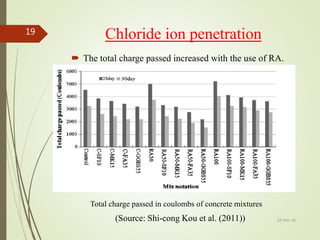

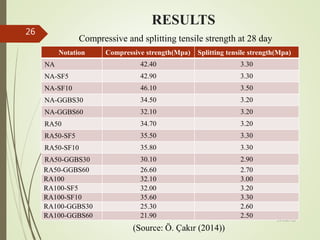

The document discusses the impact of various mineral additions on the performance of green recycled aggregate concrete (GRAC) made with recycled concrete aggregates. It presents case studies examining the effects of different mineral admixtures, such as silica fume, fly ash, and ground granulated blast slag, on strength and durability properties when used in combination with recycled aggregates. The findings indicate that while strength can decrease with higher recycled aggregate content, the use of specific mineral additives can enhance both the strength and durability of GRAC.