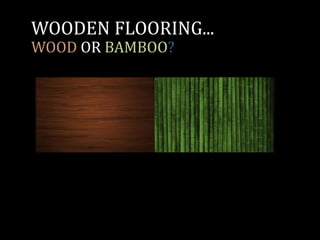

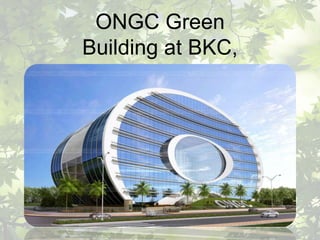

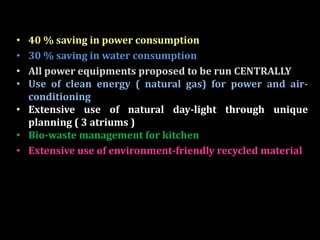

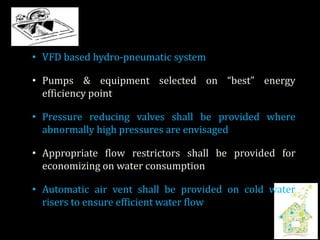

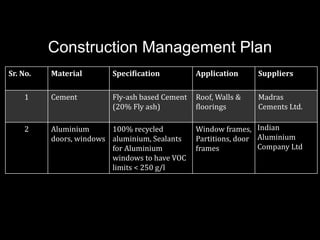

This document discusses green and sustainable interior design. It emphasizes using natural materials that are renewable, recycled, or biodegradable. Examples include wood, stone, jute and wool flooring and carpets. Eco-friendly paints with low or zero VOCs are recommended. The document also highlights the importance of energy and water conservation through features like daylighting, efficient HVAC and plumbing systems. Construction should utilize recycled materials and minimize waste. Overall the goal is to reduce environmental impact and respect the planet for future generations.