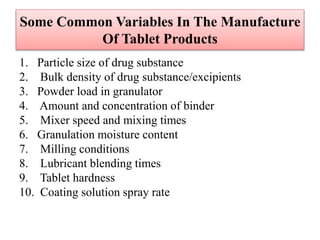

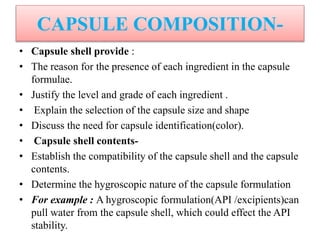

This document discusses the validation process for solid dosage forms such as tablets and capsules. It begins with an introduction to process validation and its importance in ensuring product quality. The main types of process validation are then described: prospective, concurrent, and retrospective. Specific steps in tablet and capsule manufacturing that require validation are also outlined, including validation of raw materials, analytical methods, equipment, and process parameters. Key factors considered during validation of processes like blending, granulation, drying, and milling are defined. The overall goal of process validation is to provide high assurance that the manufacturing process will consistently produce products meeting quality standards.