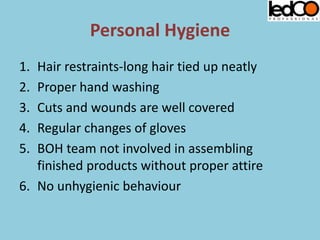

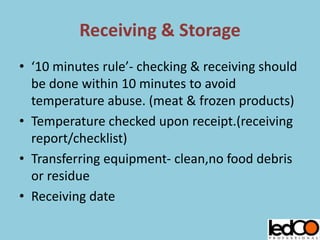

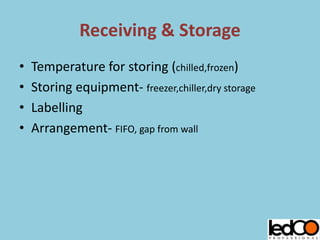

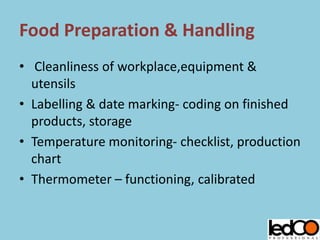

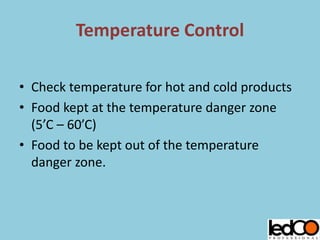

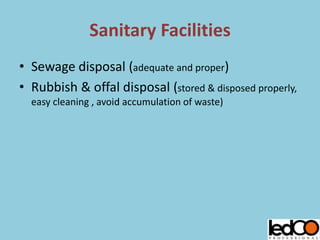

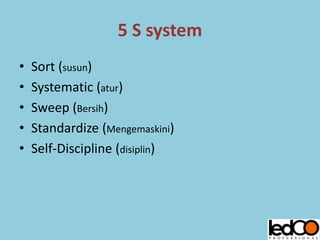

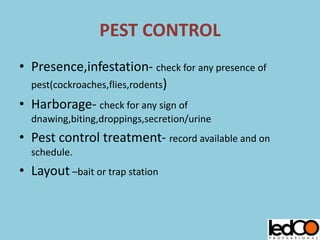

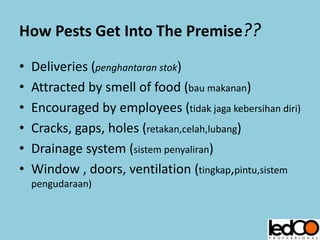

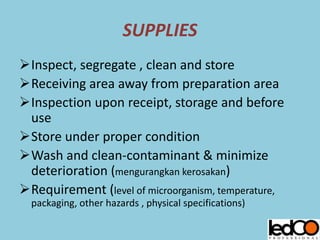

Good Catering Practice (GCP) provides recommendations for best practices in the catering industry to ensure food safety and quality. GCP objectives include ensuring food is prepared to meet safety and quality requirements by checking methods, equipment, facilities and controls from raw materials to serving. GCP also outlines proper personal hygiene and food handling practices for food handlers as well as cleaning, sanitation, pest control, storage, and documentation standards. Adhering to GCP helps catering operations implement food safety plans and meet prerequisite programs.