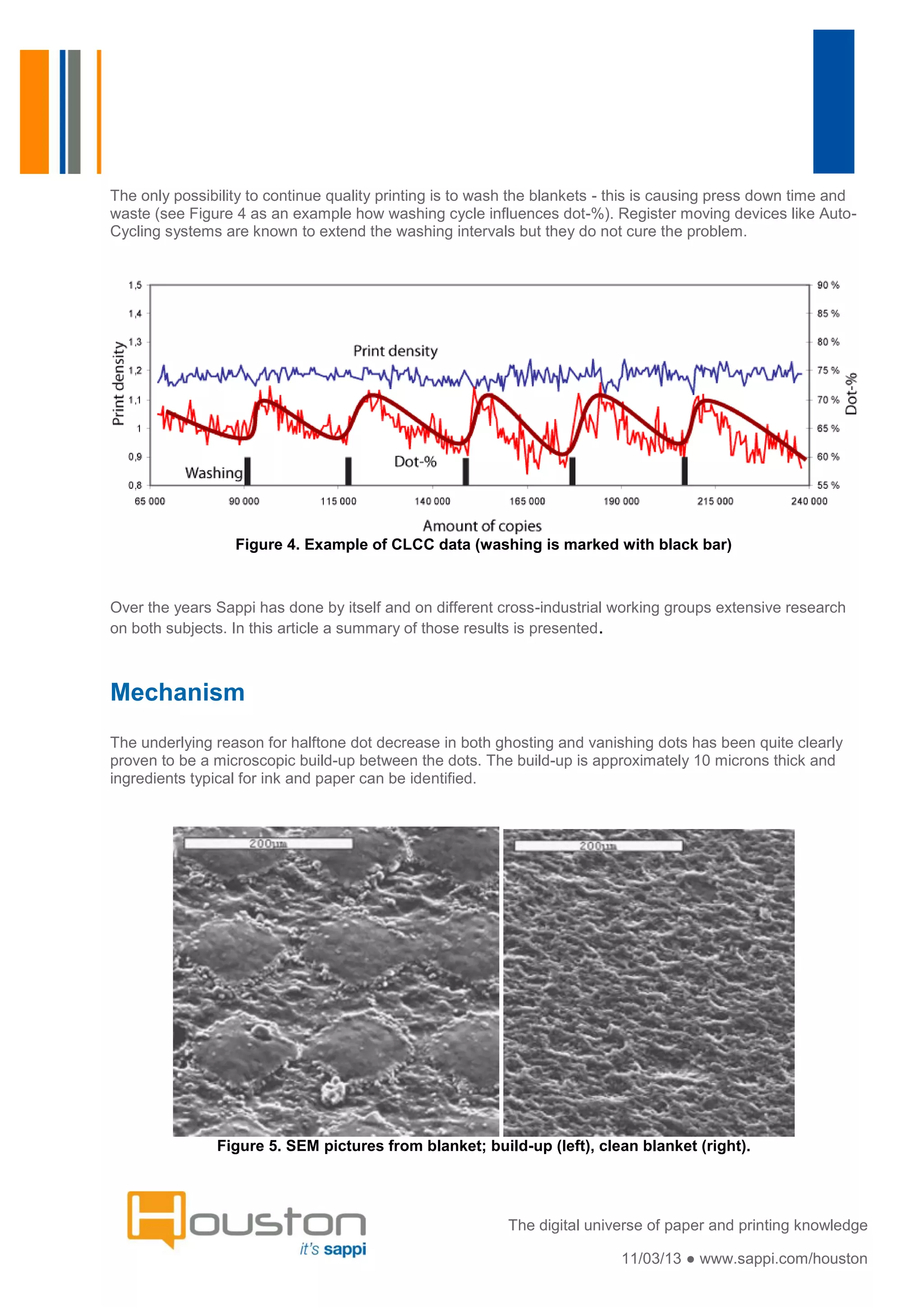

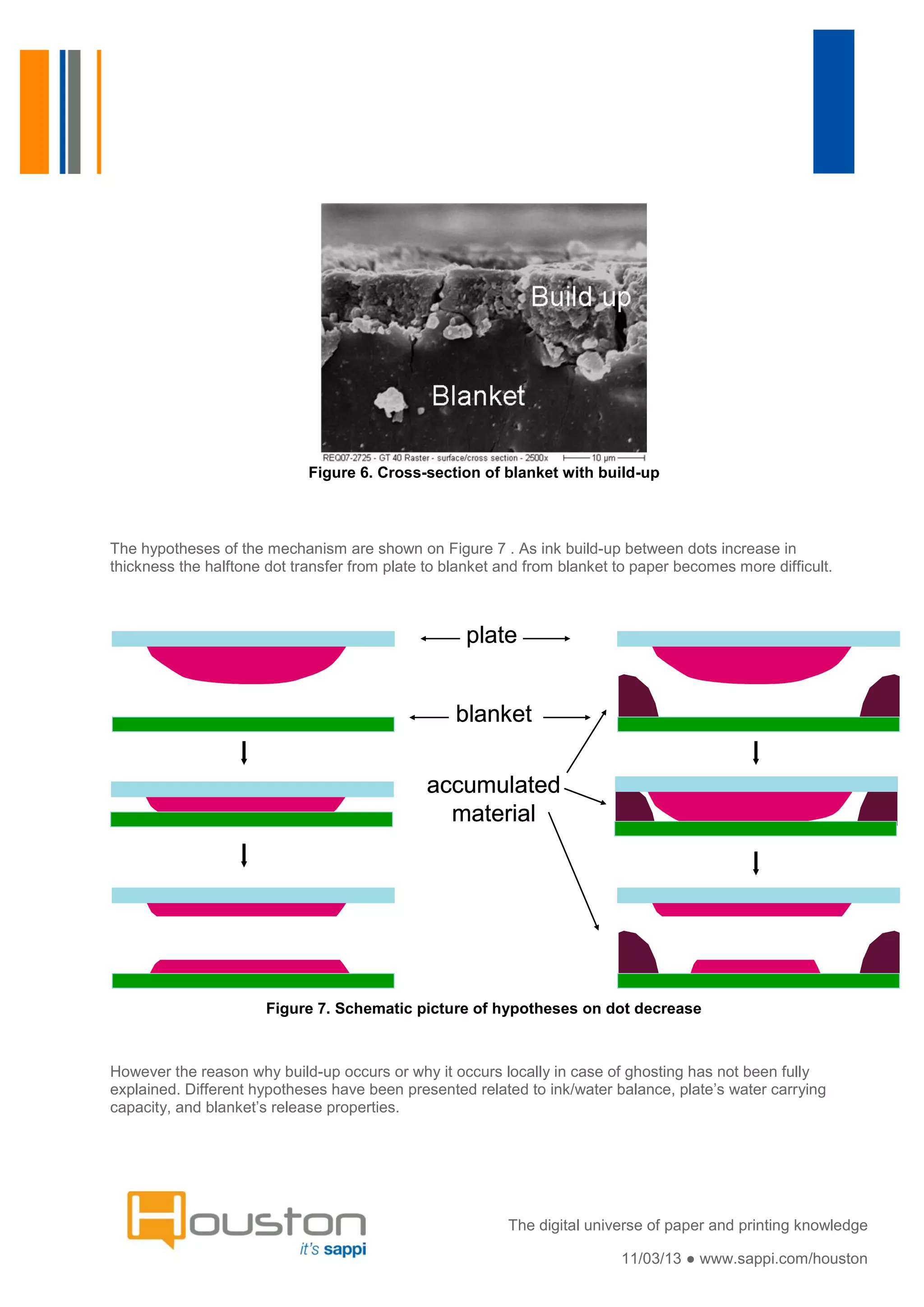

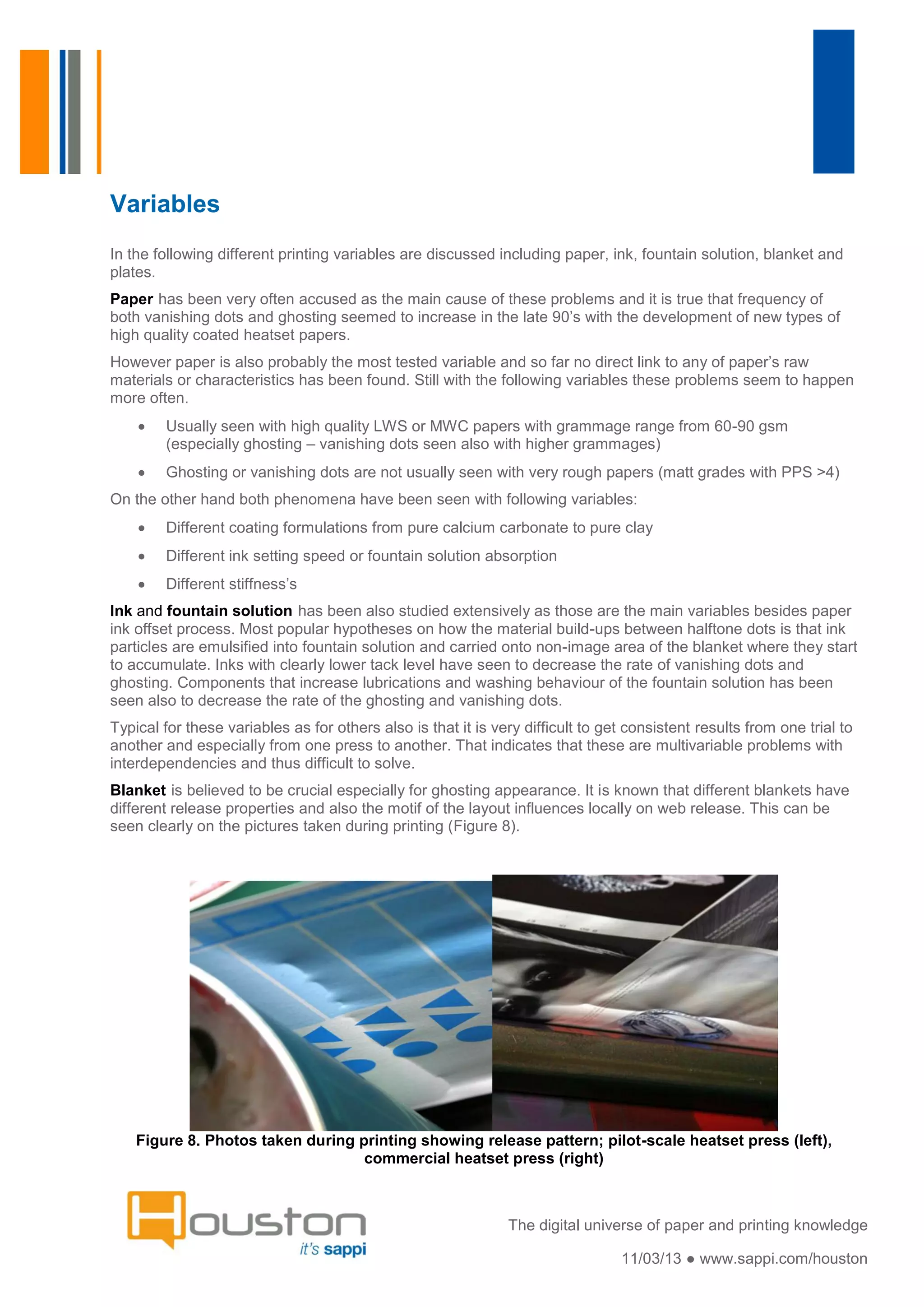

Ghosting and vanishing dots are defects that have become more prominent in heatset web offset printing in recent years. They result from a microscopic build-up of ink and paper ingredients between halftone dots over time, which makes dot transfer from plate to blanket to paper more difficult. This causes the dots to decrease in size or even disappear. Many variables can contribute to the build-up, including paper properties, ink, fountain solution, plates and blankets, but the issues are multifactorial with complex interactions and no single cause has been identified. Sappi continues to research solutions through collaborative projects.