Embed presentation

Downloaded 39 times

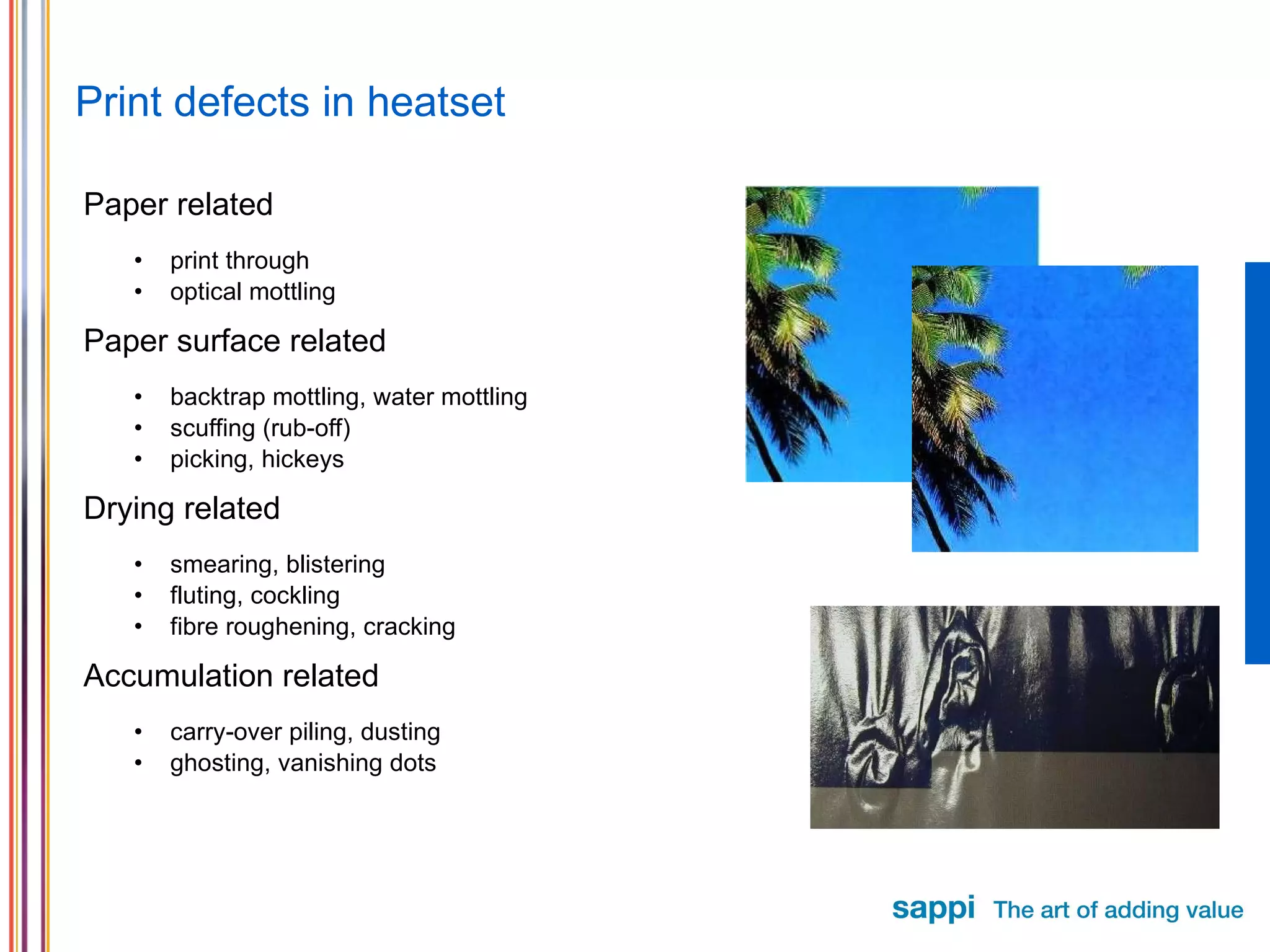

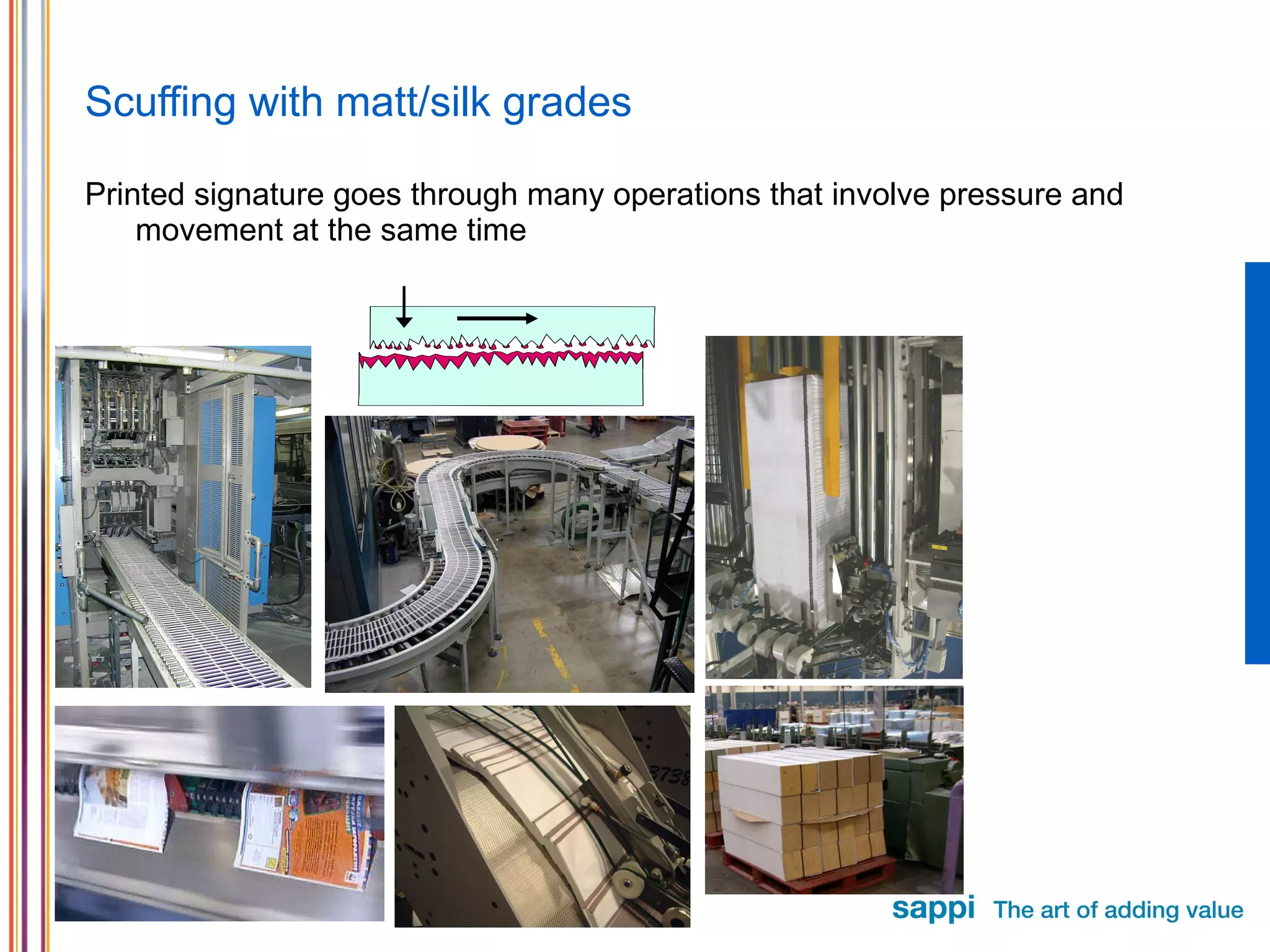

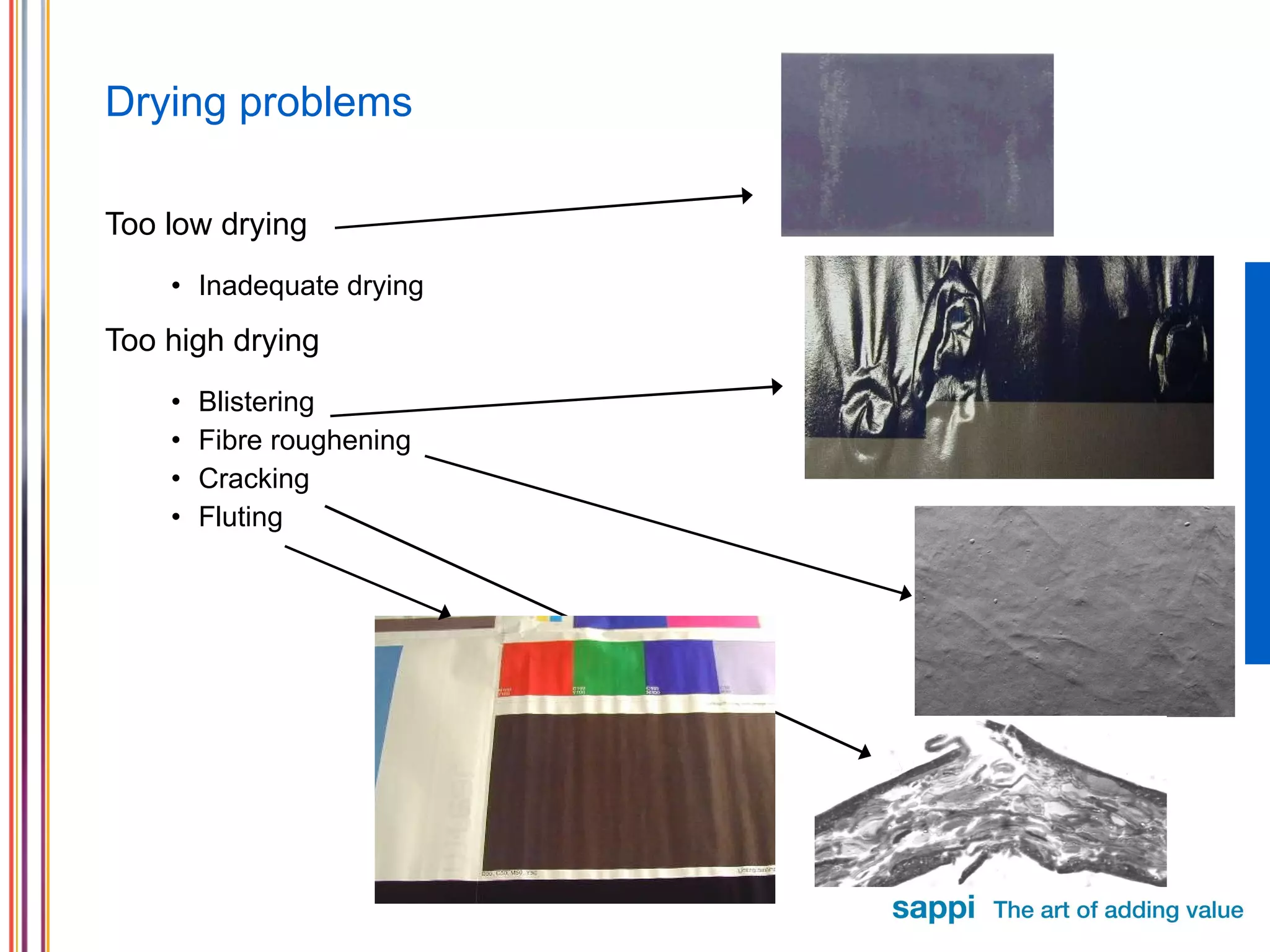

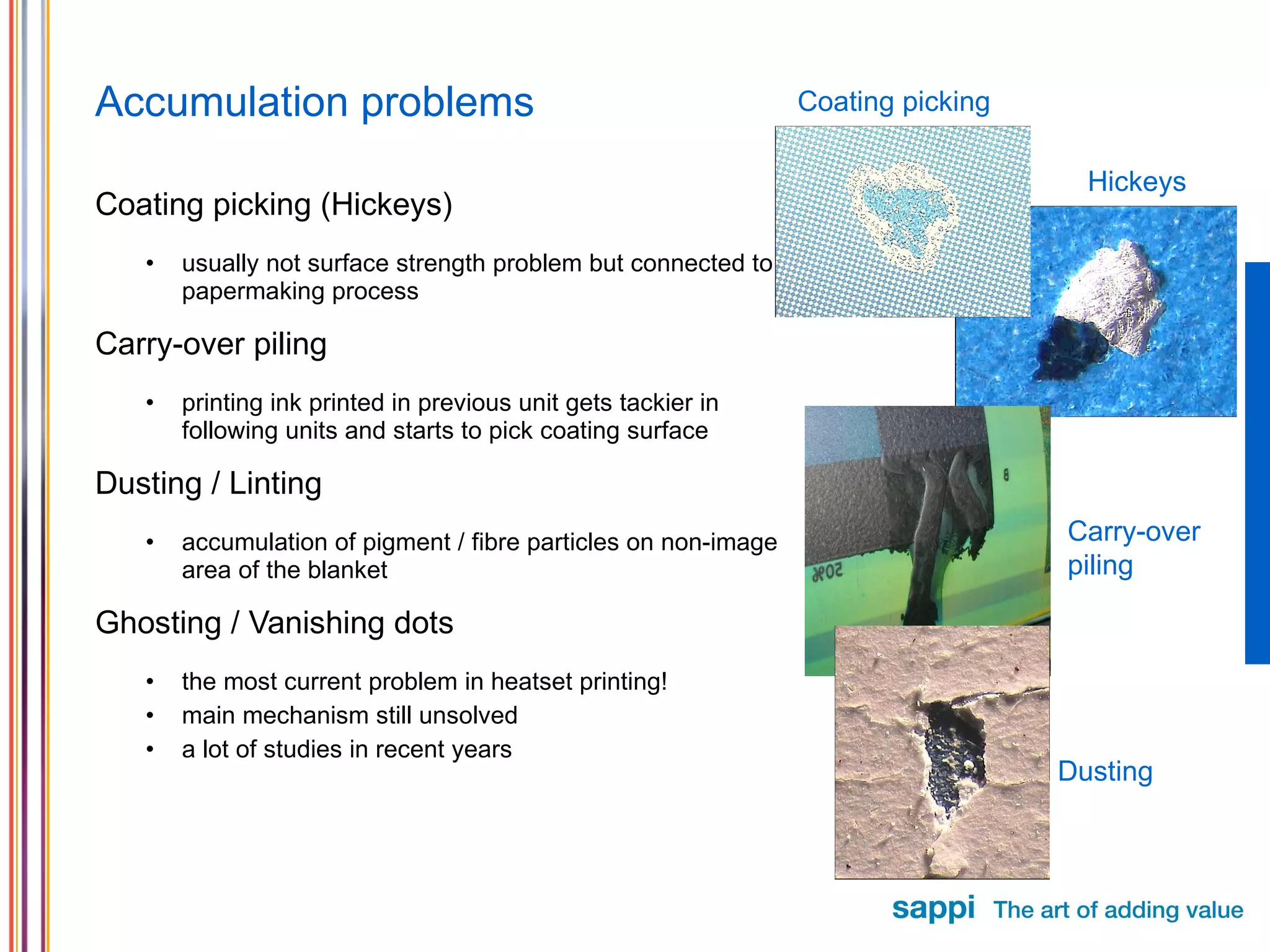

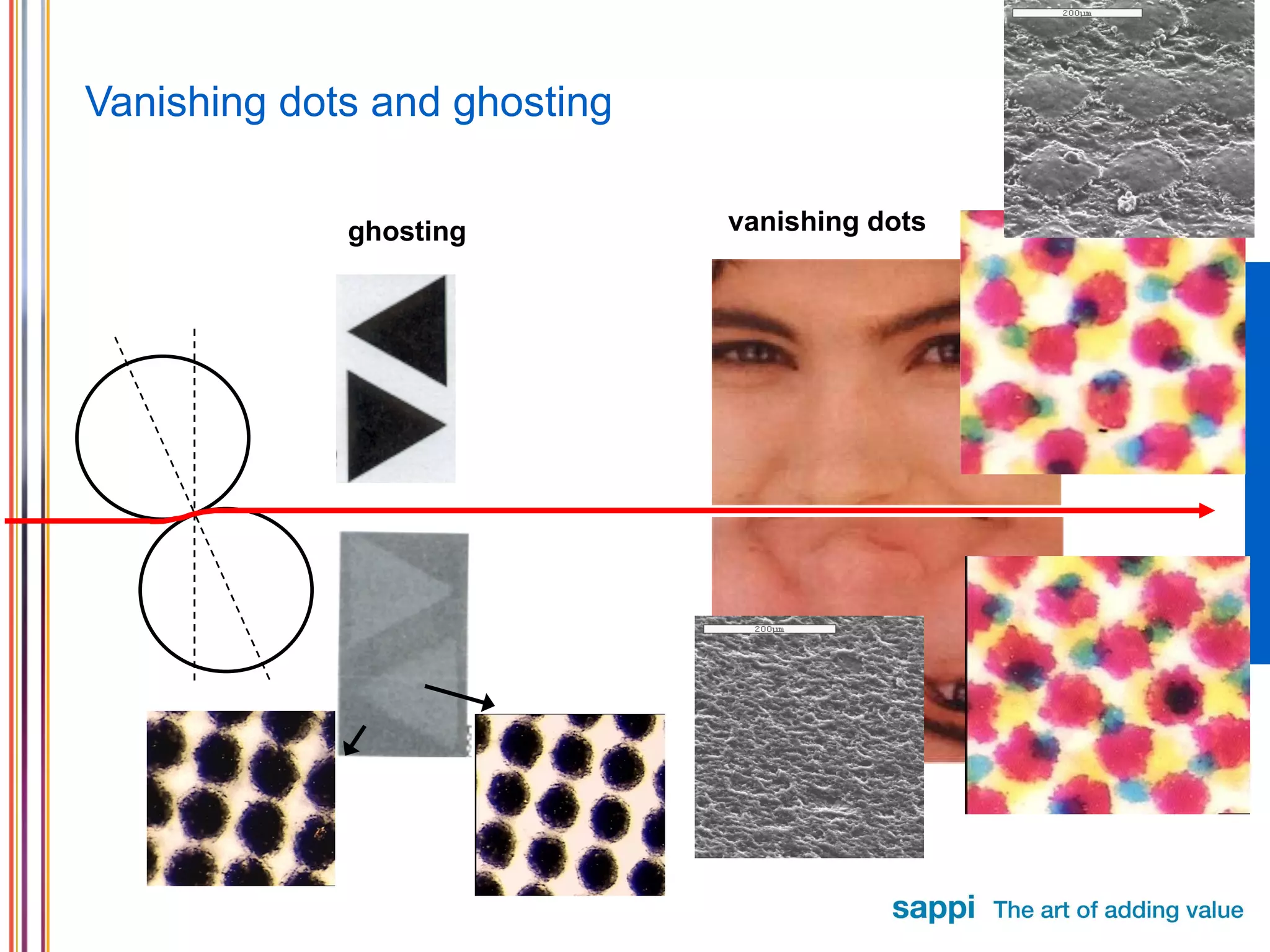

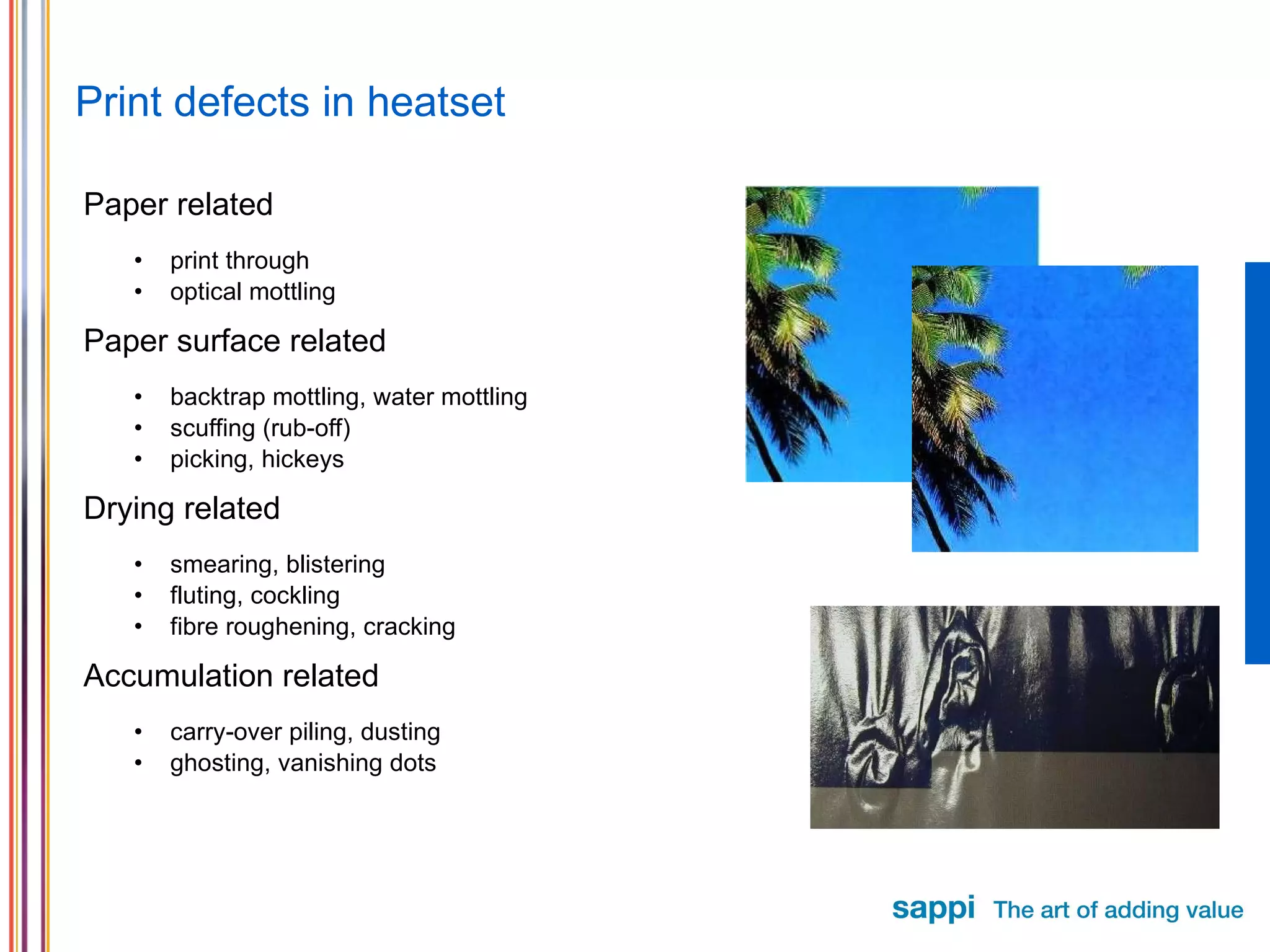

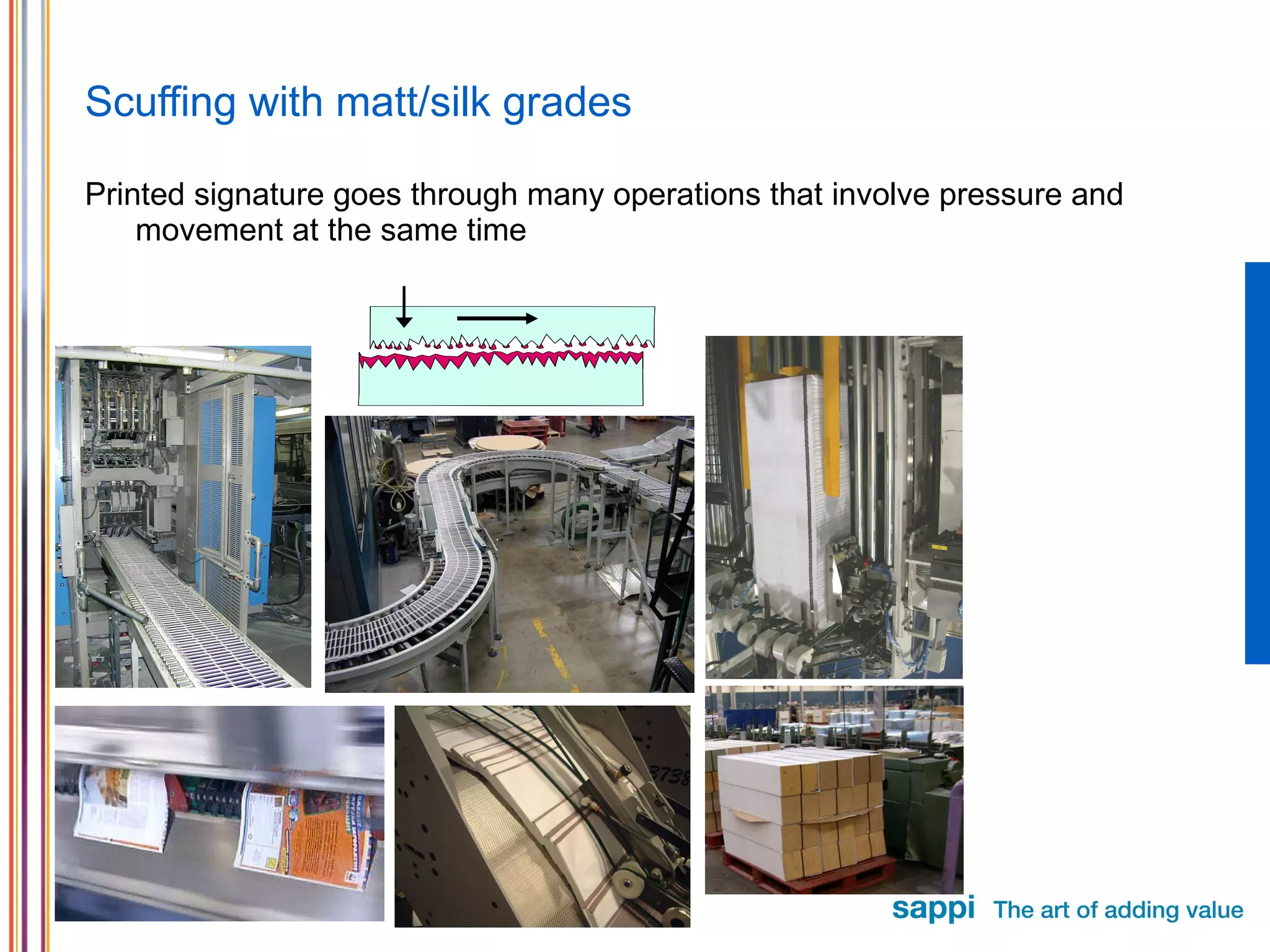

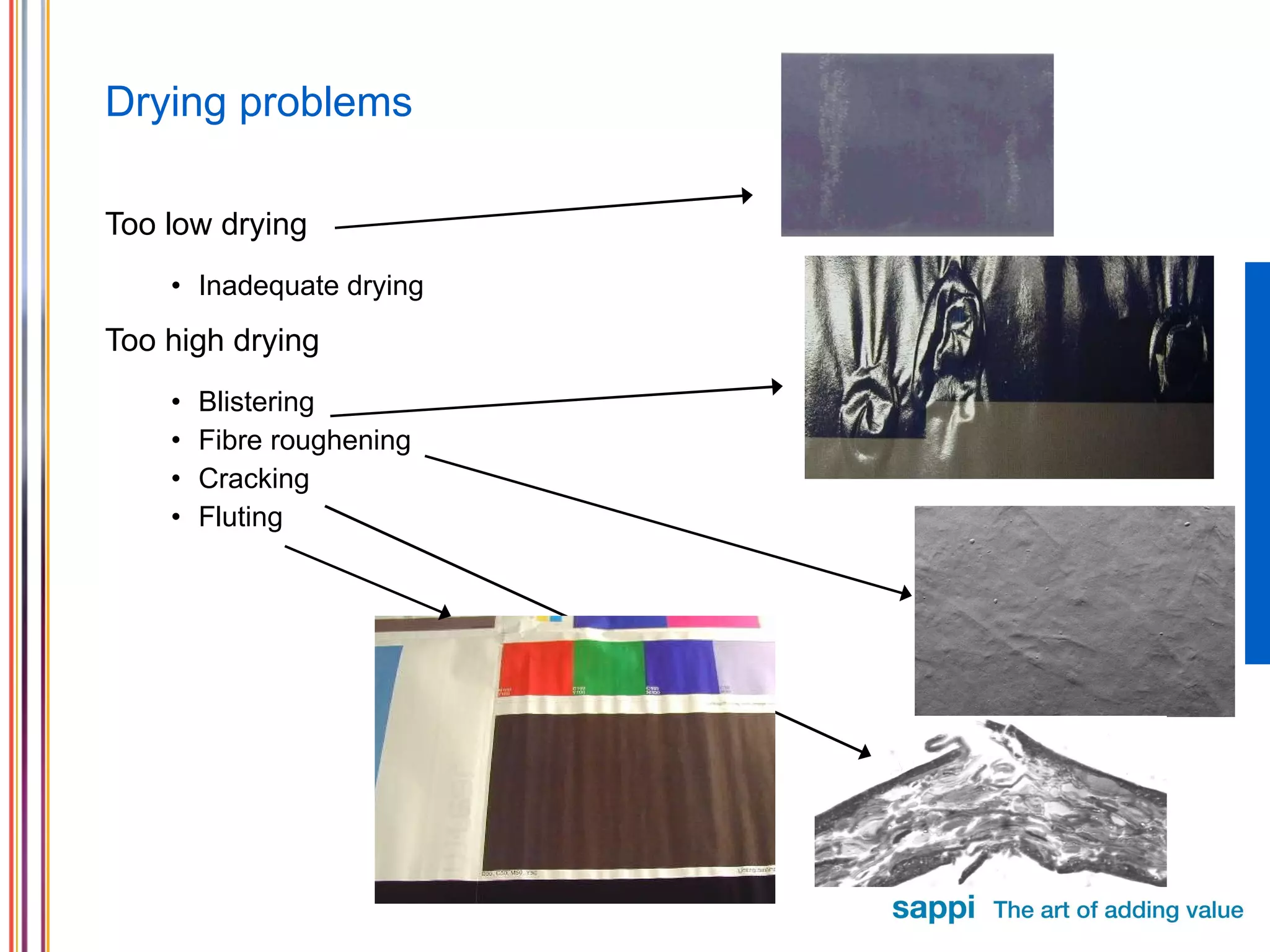

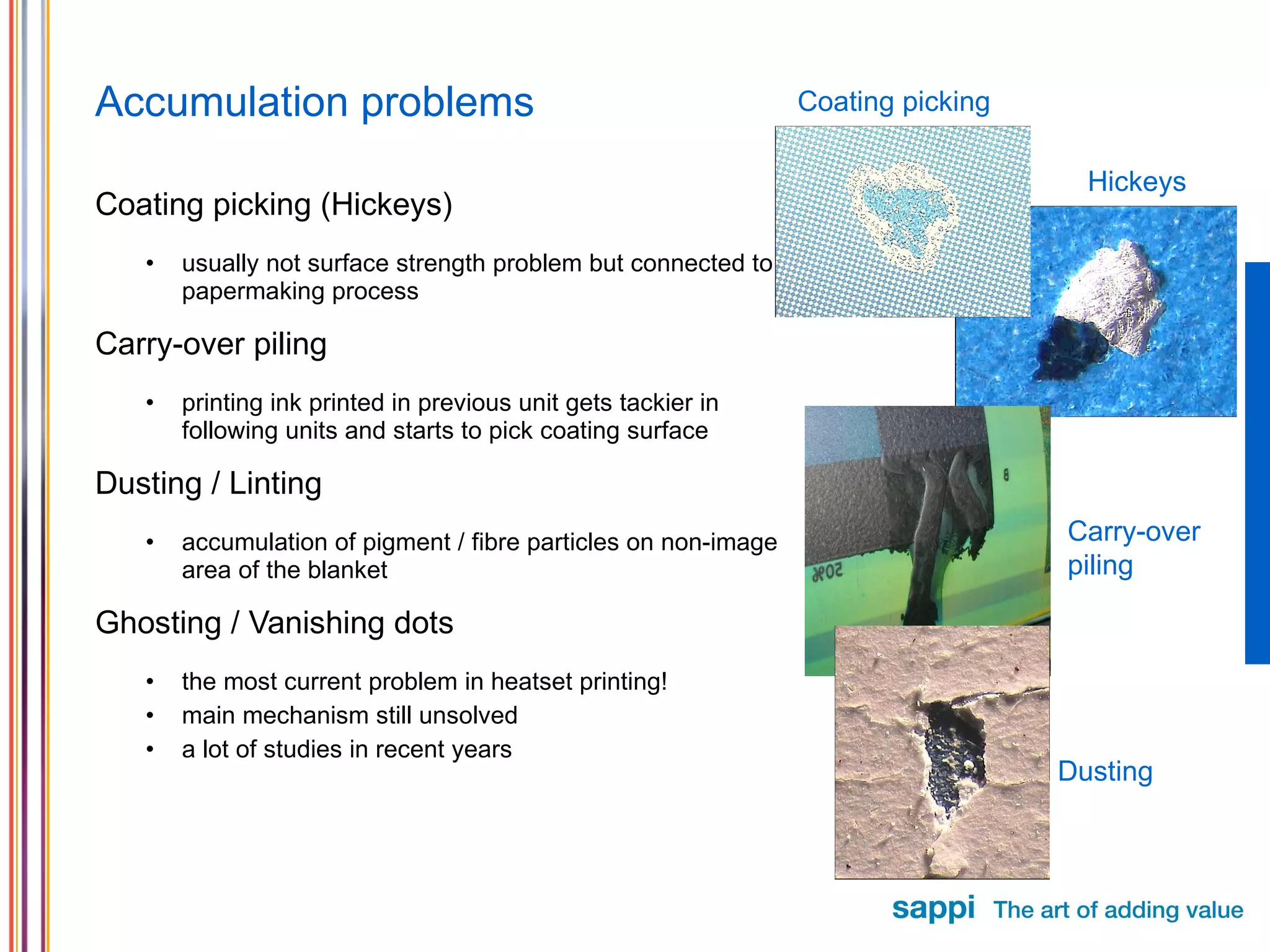

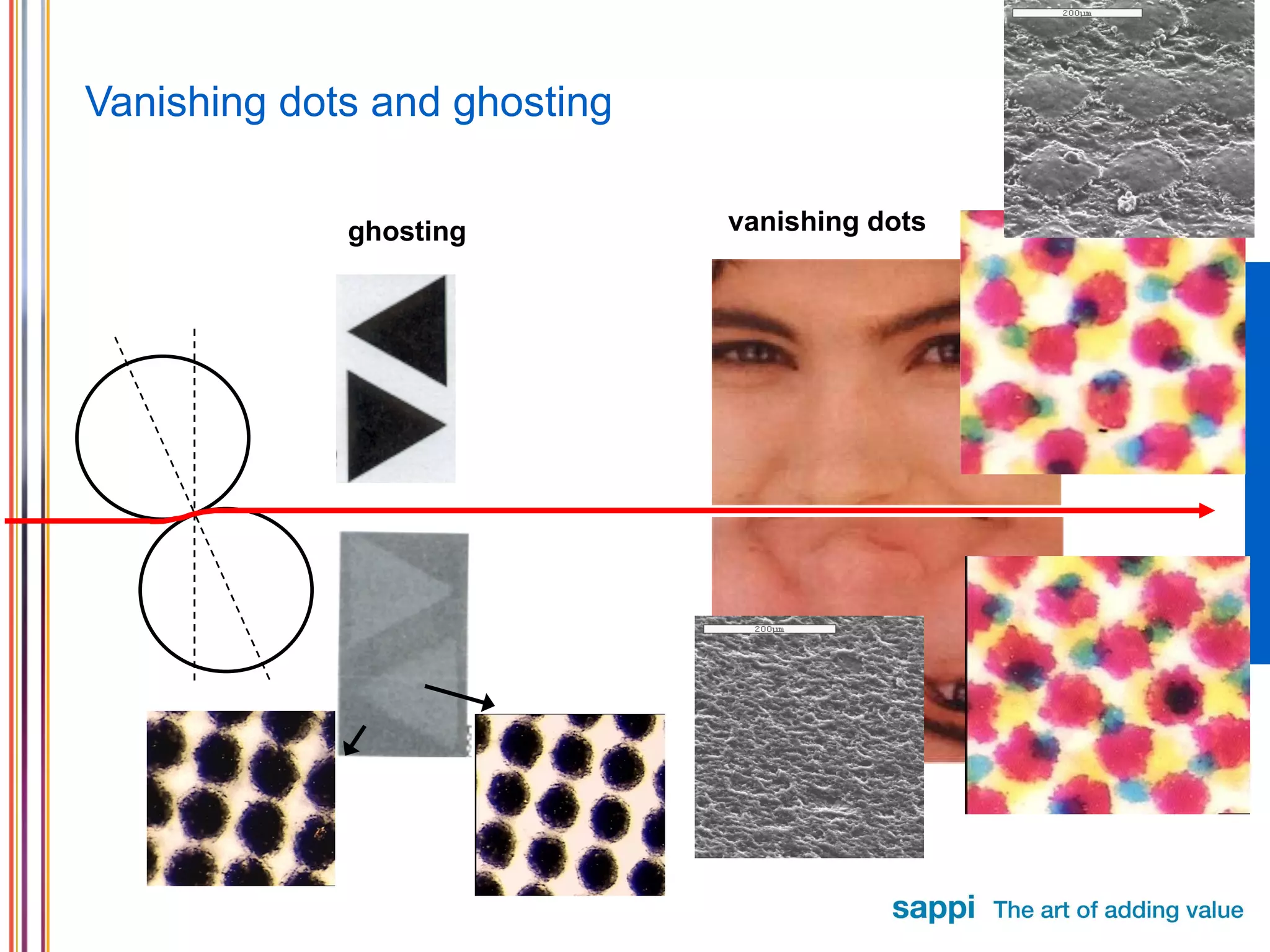

The document discusses various print defects that can occur in heatset printing processes. These include optical and surface mottling, smearing, blistering, fluting, cracking, piling, dusting, ghosting, and vanishing dots. It notes that drying problems can result from inadequate or too high drying temperatures. Accumulation on blankets over many print runs can affect runnability and quality if the washing interval is reduced significantly. Specific accumulation problems mentioned are coating picking, carry-over piling, dusting, linting, ghosting, and vanishing dots.