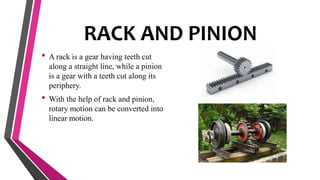

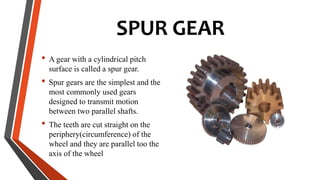

Gear drives transmit power or motion from one shaft to another using gears. The most common types of gears are spur gears, bevel gears, helical gears, worm gears, and rack and pinion gears. Spur gears have straight teeth and transmit power between parallel shafts, while bevel gears are used for perpendicular shafts. Helical gears can transmit higher loads with less noise than spur gears. Worm gears provide large speed reductions, and rack and pinion converts rotational to linear motion. These gear types are widely used in applications like machinery, vehicles, manufacturing equipment, and more.

![WORM GEARS

• Worm gear is a type of screw

gearing that consists of a screw

meshing with a helical gear or spur

gear. [‘screw’ = worm and ‘gear

wheel meshing’ = worm gear]

• Worm gears are used when large

reductions are needed especially

from 20:1 to 300:1 or greater.

• They are used to transmit power or

motion between two shafts having

their axis at right angles and non-

intersecting.](https://image.slidesharecdn.com/geardrives-191125123147/85/Gear-drives-and-it-s-types-10-320.jpg)