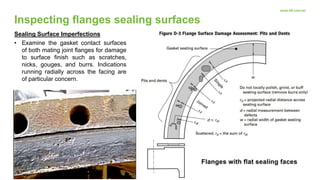

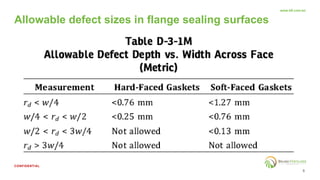

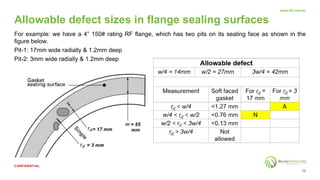

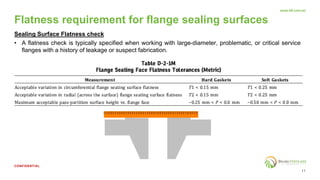

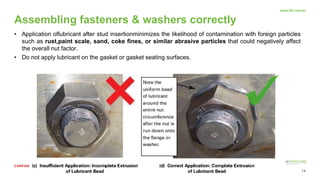

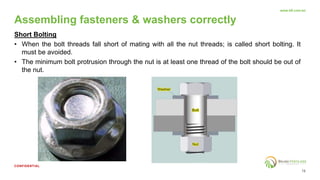

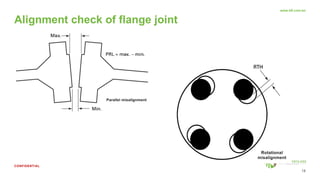

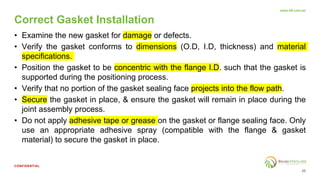

The document provides guidelines for assembling flanged connections according to ASME PCC-1 standards. It discusses cleaning and inspecting flange sealing surfaces, allowable defect sizes, flatness requirements, inspecting and assembling fasteners, aligning flanges, installing gaskets, torqueing bolts in a crisscross pattern, and performing start-up retorquing on high temperature services. The document is intended to help achieve a leak-tight integrity for properly designed bolted flange joint assemblies.