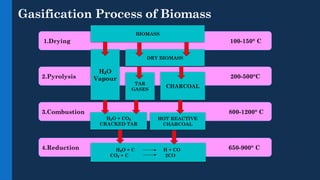

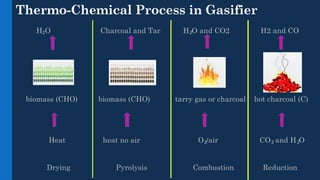

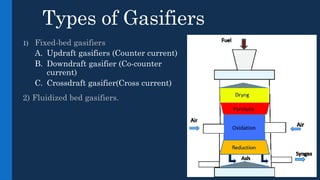

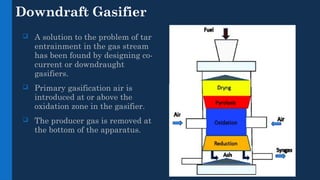

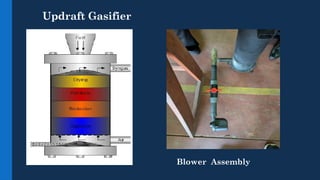

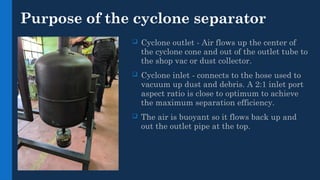

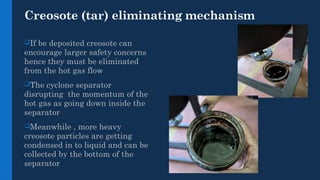

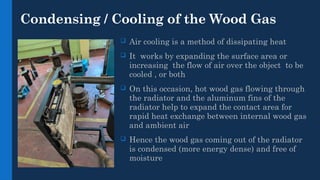

This document discusses a project on gasification, which converts biomass into producer gas through a series of thermal and chemical reactions. It details the composition of producer gas, the gasification process stages, and the types of gasifiers, highlighting the use of cyclone separators and filters for tar removal. The project aims to enhance energy recovery and reduce fossil fuel dependence by utilizing gasification technologies.

![References

National Institute of Technology, Srinagar(Retrieved March 09, 2024,

from https://www.nitsri.ac.in/)

Bioeconomy Institute(Retrieved March 15, 2024, from -Bioeconomy

Institute (iastate.edu))

Alternative Energy Promotion Centre(Retrieved March 15, 2024, from -

AEPC)

Bio Energy Association of Sri Lanka(Retrieved March 15, 2024, from -

Bio Energy Association of Sri Lanka (bioenergysrilanka.lk])

Food and Agriculture Organization of the United Nations(Retrieved

March 15, 2024, from https://www.fao.org/home/en)](https://image.slidesharecdn.com/sahanaiyapresentation-5-240914083235-1f0b0d95/85/Gasifier-construction-and-demonstration-pptx-17-320.jpg)