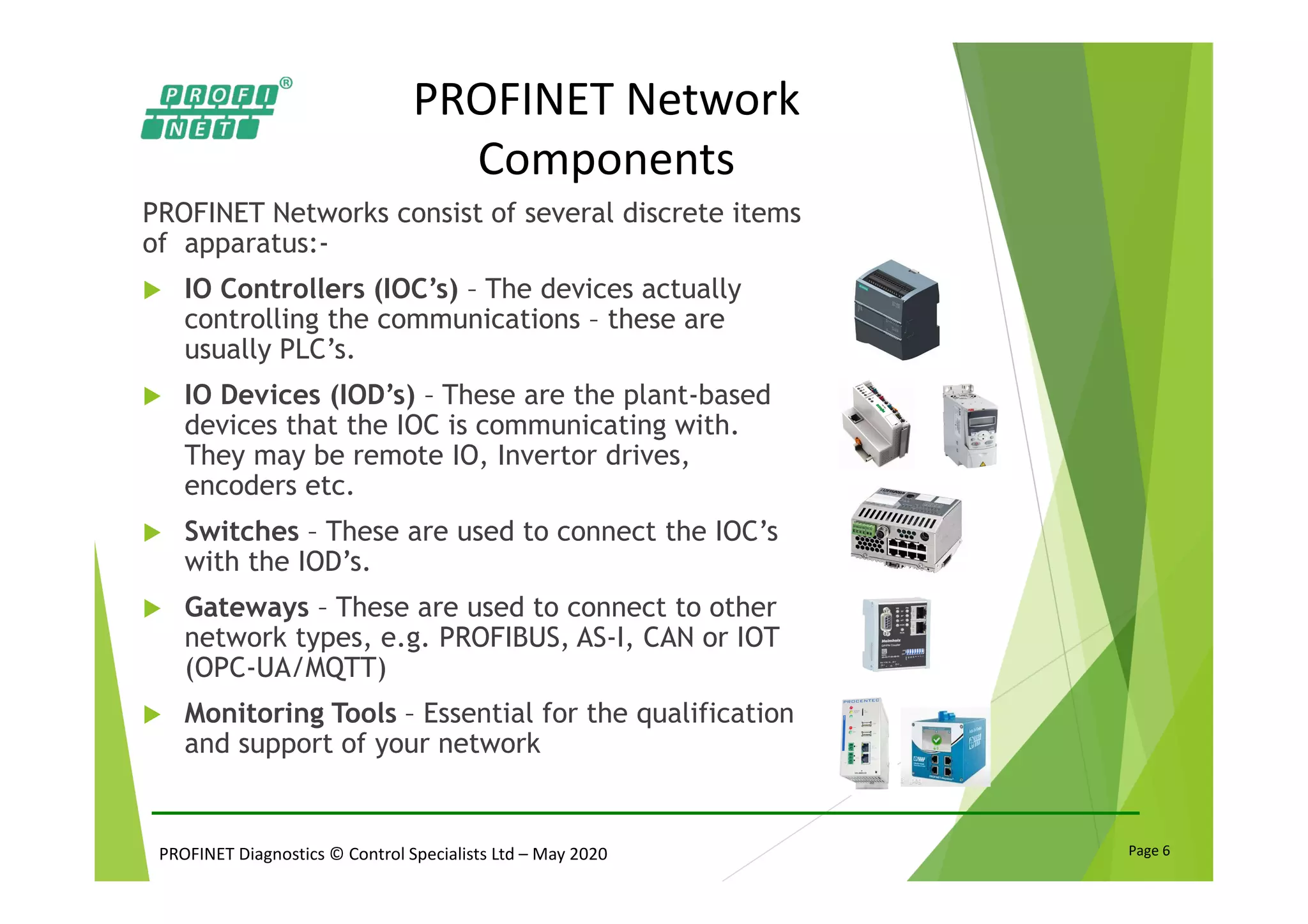

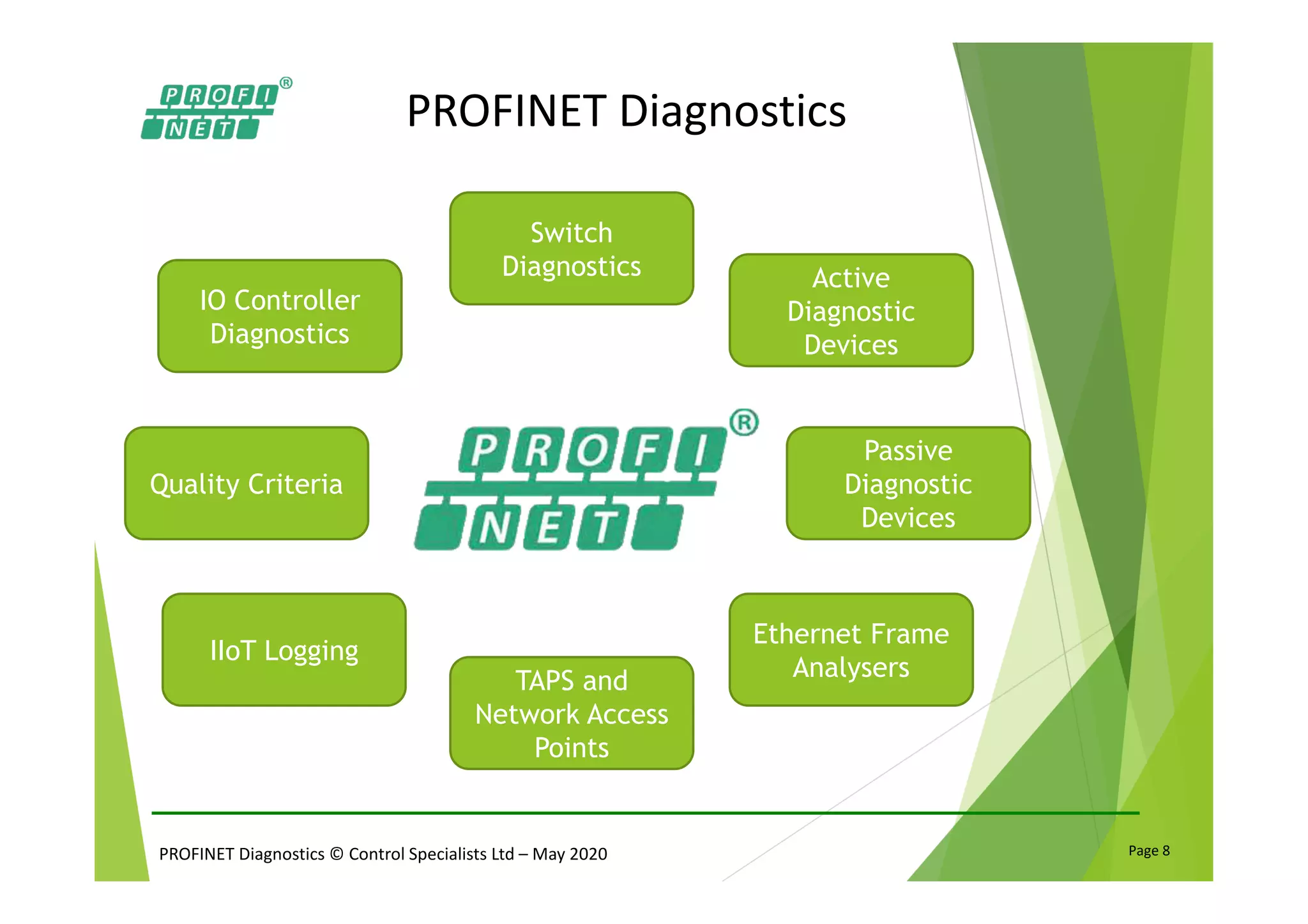

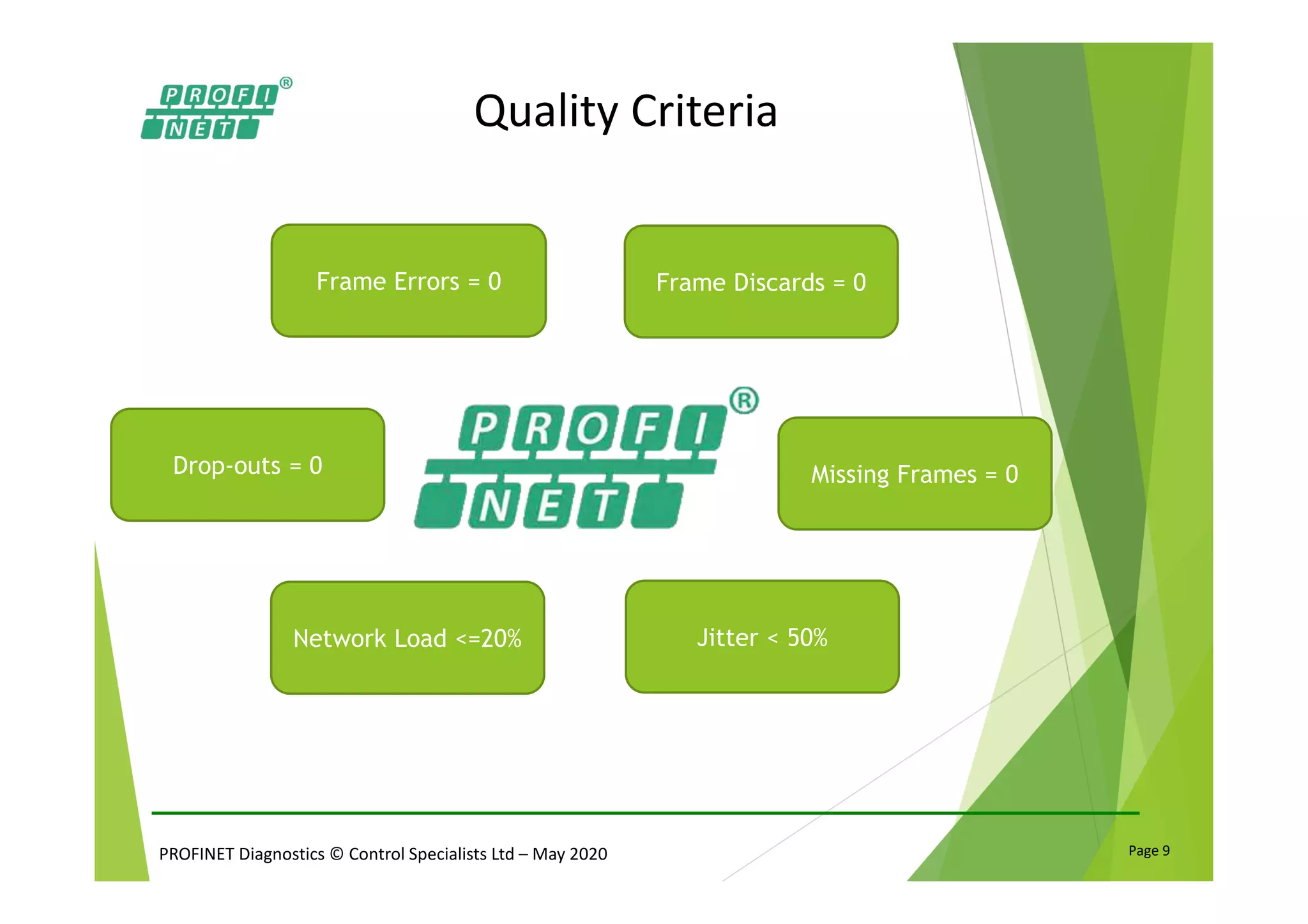

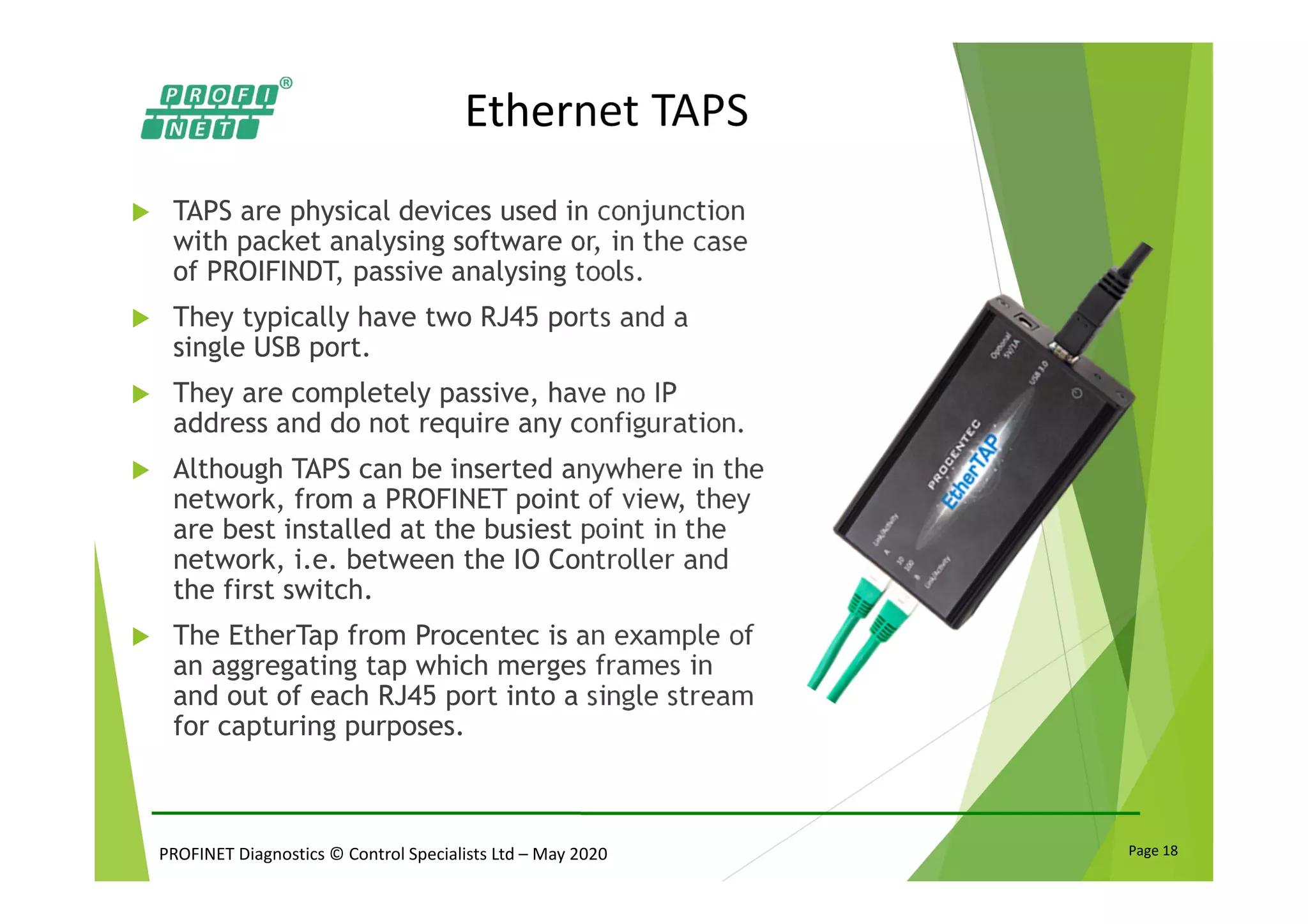

This webinar presentation provides information on diagnosing PROFINET networks. It discusses various diagnostic tools that can be used, including those within IO controllers, switches, and third-party hardware and software. Specific tools covered are active and passive diagnostic devices, Ethernet frame analyzers, port mirroring, and Ethernet taps. The presentation emphasizes the importance of proper network design and qualification to ensure issues can be identified and supported. Control Specialists offers various PROFINET training courses.