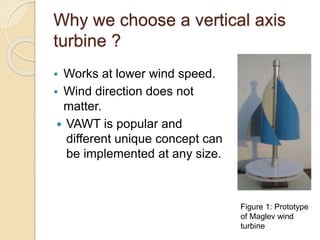

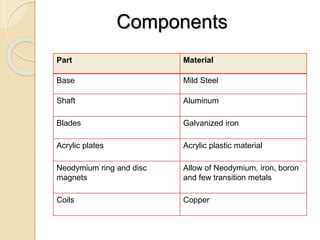

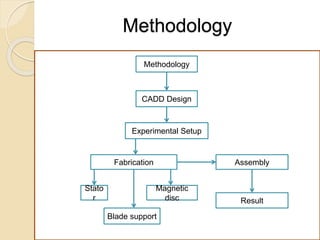

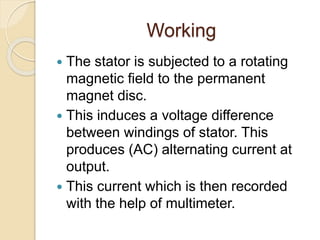

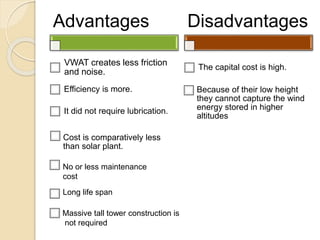

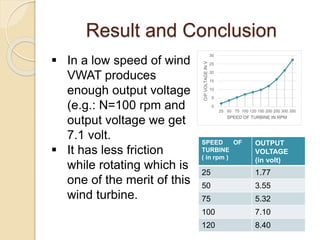

The document presents a project on a frictionless wind turbine utilizing magnetic levitation technology for improved efficiency in energy generation from wind. The focus is on a vertical axis wind turbine (VAWT) designed to operate effectively at lower wind speeds and without lubrication. While the prototype exhibits advantages such as reduced friction and noise, high capital costs and limitations in capturing wind energy at greater heights are noted.