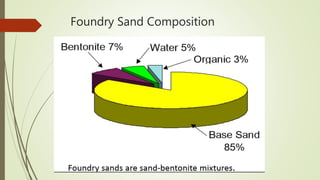

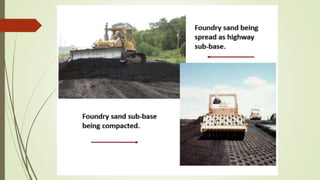

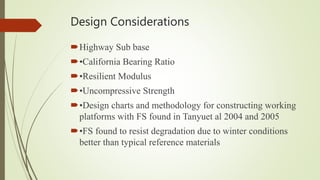

Foundry sand is a high-quality silica sand used to make molds for metal casting. It typically contains silica sand, bentonite clay, water, and coal. Approximately 9-10 million tons of foundry sand is discarded each year. Some discarded foundry sand can be reused in construction after testing shows metals and chemicals meet environmental thresholds. Using foundry sand in construction has advantages like reducing costs and waste compared to using only virgin materials. It can be used in highway bases and embankments if designed correctly.