This document discusses an experimental study on the use of foundry sand as a partial replacement for fine aggregate in reinforced concrete beams. Foundry sand is a waste byproduct from metal casting industries. The study aims to utilize this waste material in concrete production. Concrete cubes and beams were cast using foundry sand replacements of 0-100% in increments of 10%. Beams were cast with a rounded rectangular opening. Testing found that a 40% replacement of foundry sand provided the maximum compressive strength. Beams were then cast using the 40% optimized mix and tested under two-point loading. Test results showed that foundry sand can be used as a partial replacement for fine aggregate in concrete, improving strength and providing an outlet for an

![International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 04 Issue: 08 | Aug -2017 www.irjet.net p-ISSN: 2395-0072

© 2017, IRJET | Impact Factor value: 5.181 | ISO 9001:2008 Certified Journal | Page 1764

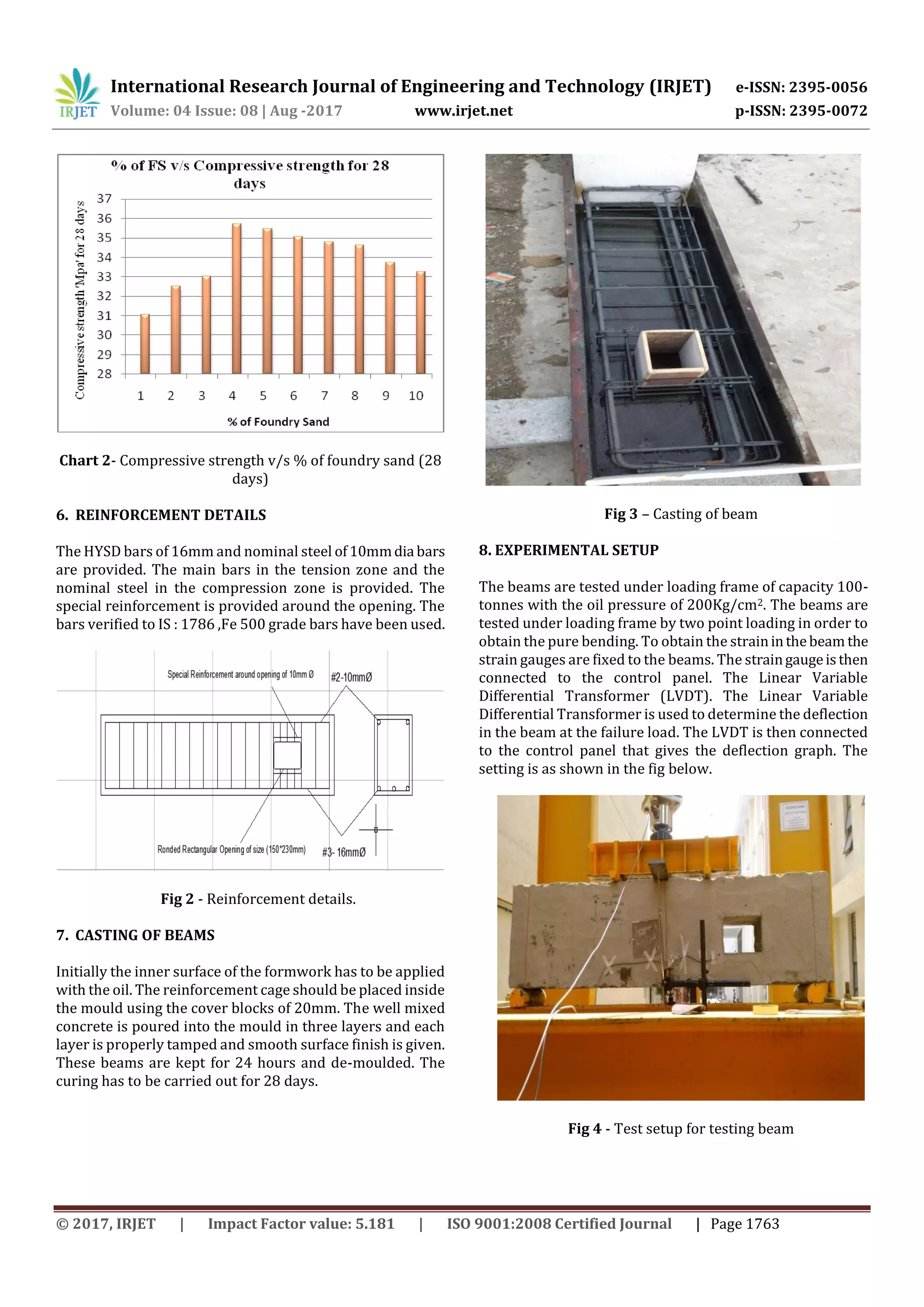

Fig 5 - The failure of beam after the test

Chart 3- Load v/s Deflection with replacement

Chart 4- Load v/s Deflection with replacement

9. CONCLUSION

From the experimental resultsobtainedfromthiswork on

the beams of M30 grade the subsequent conclusion were

established.

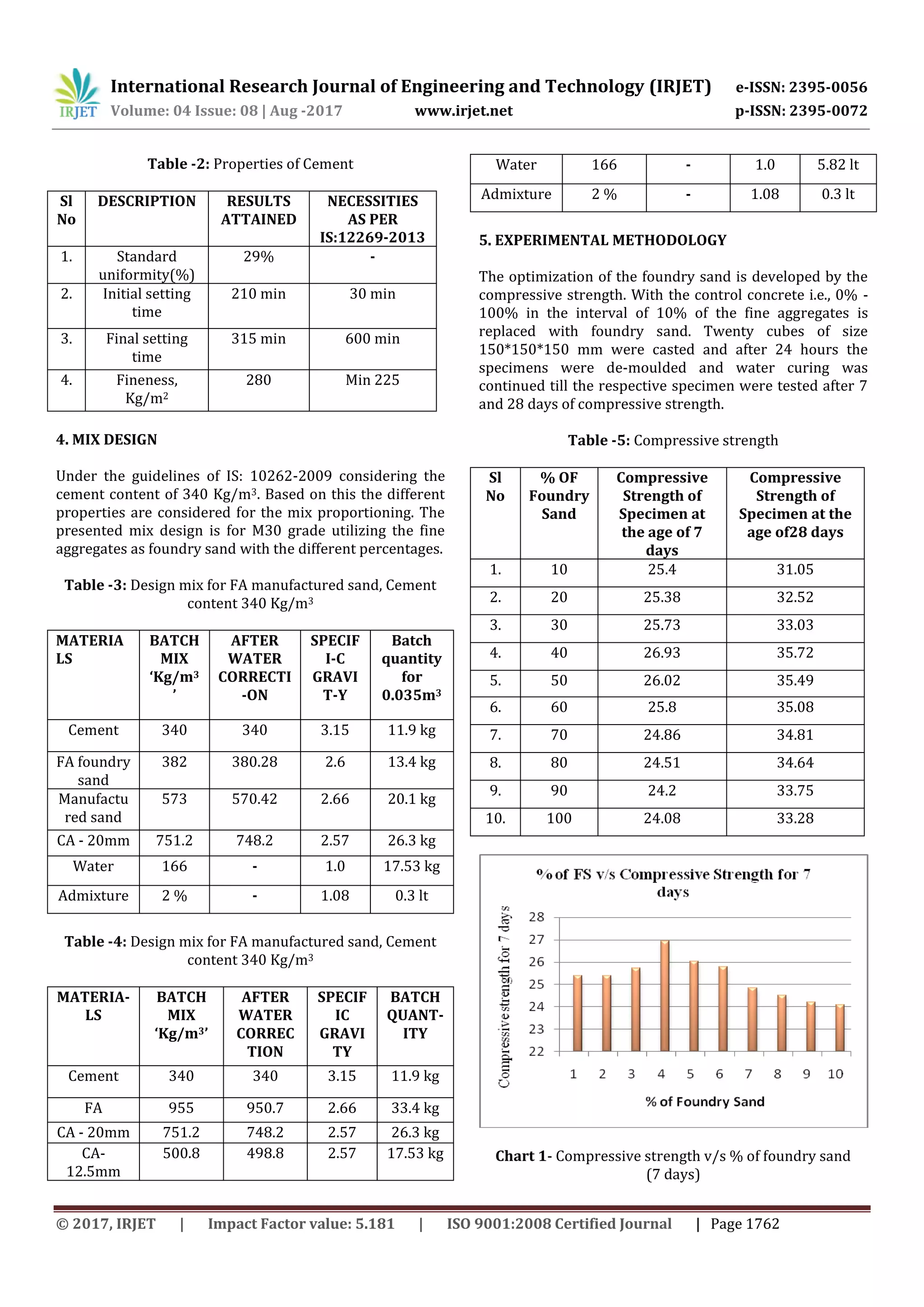

1. The optimized value of foundry sand obtained as 40%

for 28 days of compressive strength. The compressive

strength obtained was in and around to the conventional

concrete.

2. The compressive strength gradually increased with the

addition of the foundry sand.

3. From the compressive strengthresults,thereplacementof

foundry sand material gives highest strength for 40%.

4. The use of the foundry sand used in concrete in other

word is known as green sand obtained from steel industries

reduces the landfilling and hazardous effects on nature.

REFERENCES

[1] “Replacement of fine aggregates with in concrete” by

Deepak Chaurasiya, Kiran Koli, Suraj Chaudhari –

International Journal on Theoretical and Applied

Research in mechanical Engineering. Volume 5, Issue 1,

February 2016.

[2] “Flexural behavior of RC beams using as partial

replacement of fine aggregates” by Umashankar A,

Shashikumar A. International Journal of Research in

Engineering and Technology. Volume 5, Issue 8, August

2016.

[3] “Effects of as a fine aggregate in concrete production”

entitled by G.GaneshPrabhu, JungHwanHyun, YunYong

Kim - Science Direct, September 2014.

[4] “Effect of on the mechanical properties of concrete” by

Rafat Siddique, Geert de Schutter – Science Direct.

[5] Gurpreet Singh, Rafat Siddique as “Effect of waste as

partial replacement of sand on the strength,ultrasonic

pulse velocity and permeability of concrete” – Science

Direct.

[6] “Waste foundry sand as a replacementforfineaggregate

in high strength solid masonary blocks”, by Mahima

Ganeshan, Dr.Sreevidya V. International Journal of

InnovativeResearchinScience,EngineeringTechnology.

[7] “Flexure behavior of reinforced concrete beams with

opening” by Saeed Ahmed Sheikh, Concrete Research,

Volume 5(2), June 2014.

[8] “Flexure behavior of reinforced concrete beams with

opening” by Saeed Ahmed Sheikh, Concrete Research,

Volume 5(2), June 2014.](https://image.slidesharecdn.com/irjet-v4i8313-170922105055/75/Experimental-and-Anlytical-Behavior-of-Reinforced-Concrete-Beams-with-Opening-using-Foundry-Sand-5-2048.jpg)