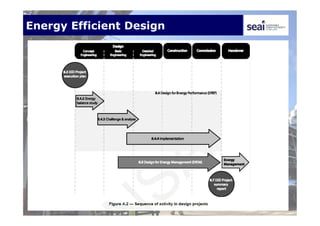

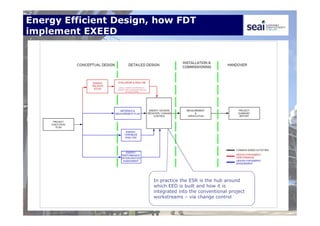

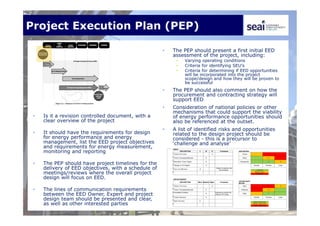

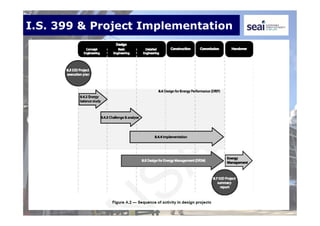

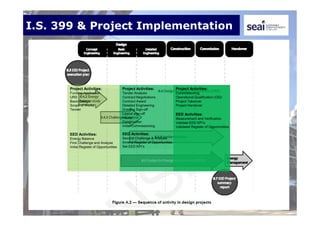

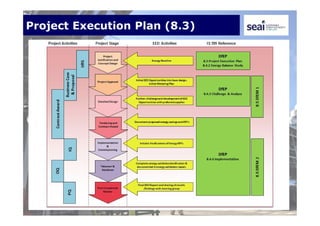

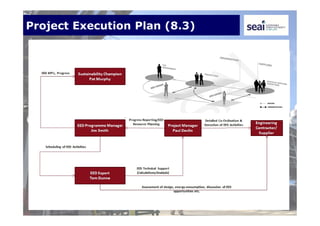

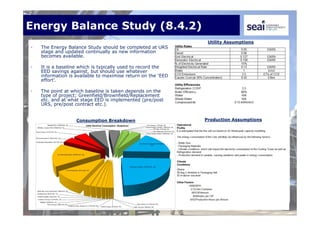

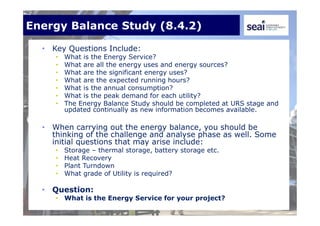

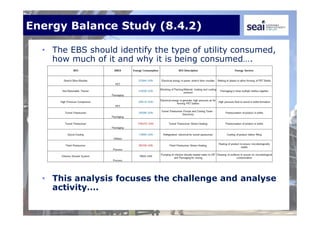

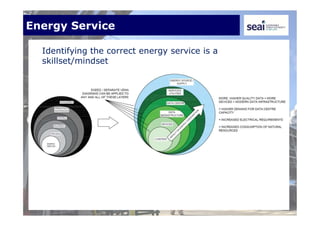

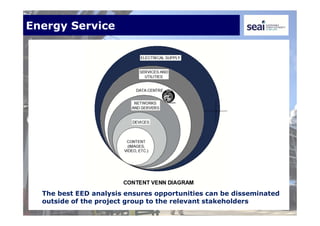

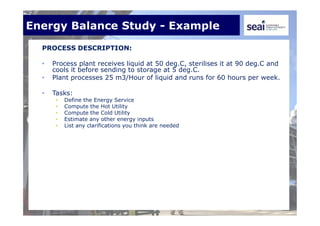

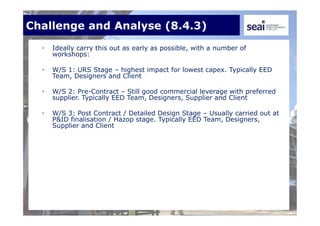

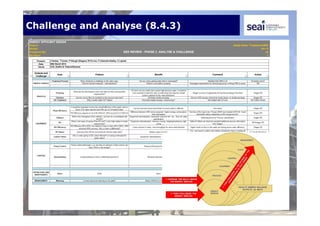

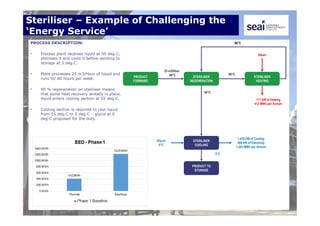

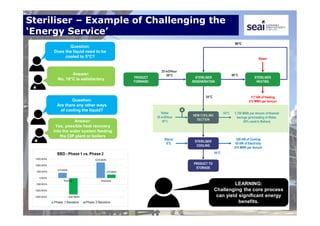

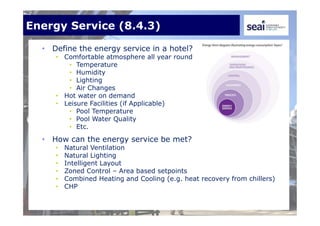

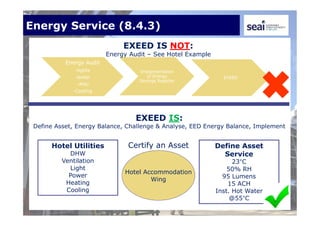

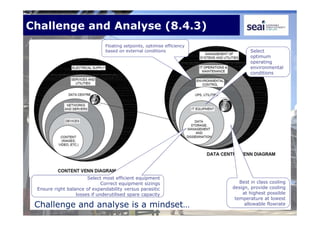

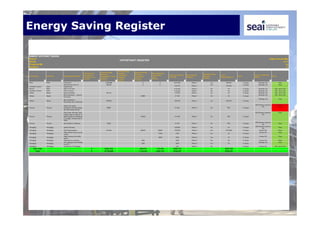

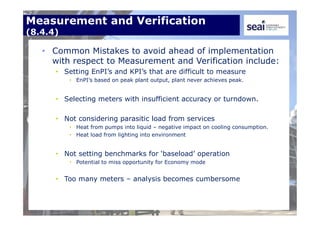

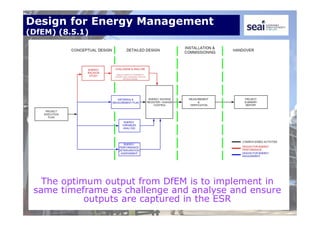

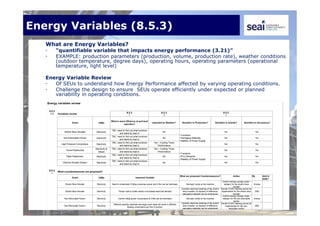

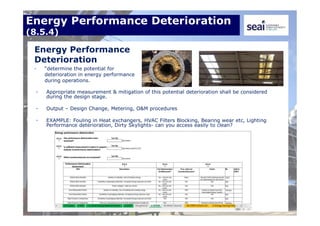

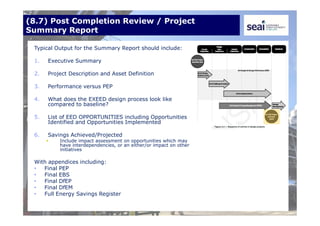

The document outlines a workshop on maximizing energy efficiency in data centre design using the EXEED methodology, emphasizing the importance of energy efficient design (EED) and energy management principles integrated throughout the project lifecycle. It details stages such as energy balance studies, challenge and analyze workshops, and the importance of a structured project execution plan (PEP) to ensure energy performance objectives are met. Key learnings from past projects highlight the need for early application of EED principles, client engagement, and collaboration among stakeholders to unlock energy-saving opportunities.