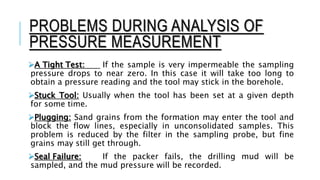

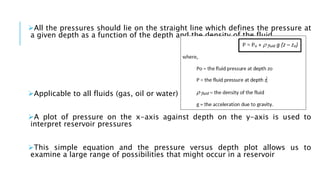

Wireline formation testing tools like the Repeat Formation Tester are used to collect fluid samples and pressure measurements from open holes. The tool is run into the well and a probe is pressed into the formation to withdraw fluid samples while maintaining downhole pressures. The samples provide information about fluid types and properties, hydrocarbon presence, and in-situ pressures. Multiple precise pressure measurements can indicate fluid contacts and compartmentalization if the pressures do not fall on a straight line gradient. Problems like tight formations, stuck tools, plugging, and seal failures can complicate pressure analysis.