This document provides an overview of the electronics components used for a robotics competition, including:

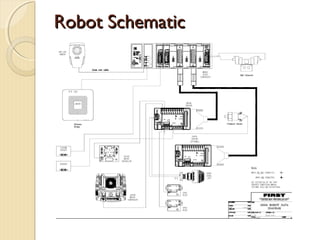

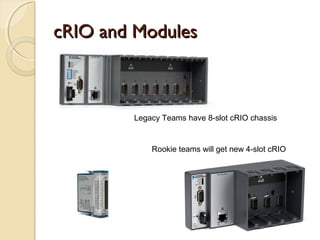

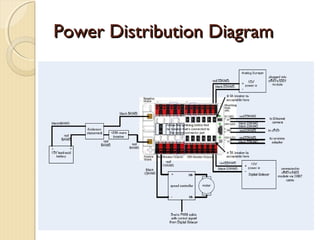

1) The control system is centered around a National Instruments cRIO controller with I/O modules. Rookie teams will receive a smaller 4-slot cRIO compared to veterans' 8-slot models.

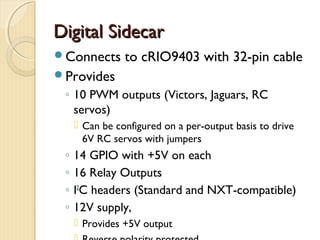

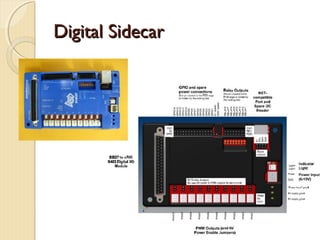

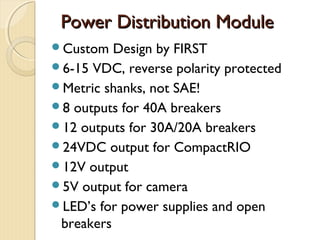

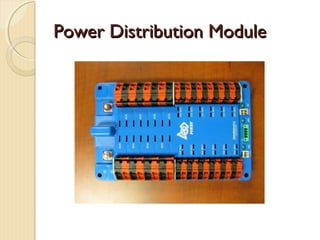

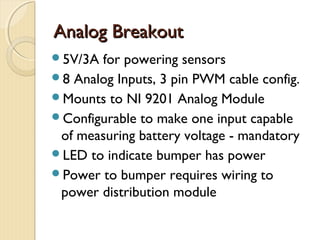

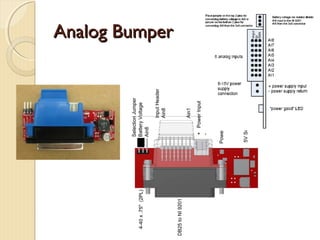

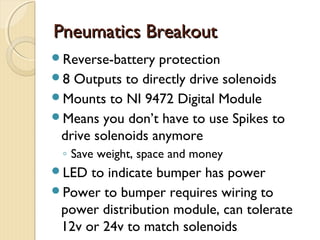

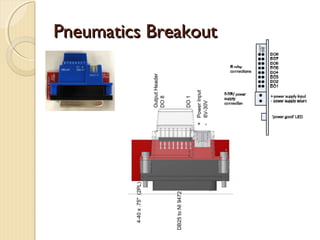

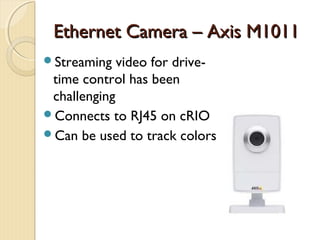

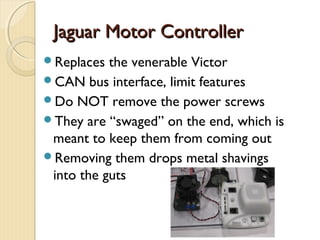

2) Other key components are a digital sidecar for PWM/DIO outputs, a power distribution module, analog and pneumatics breakouts, and motor controllers.

3) The operator interface consists of a netbook running control software connected via wireless to the cRIO, along with joysticks and a programmable I/O expansion device to monitor switches/buttons.