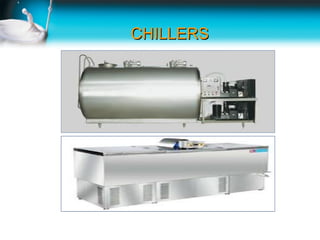

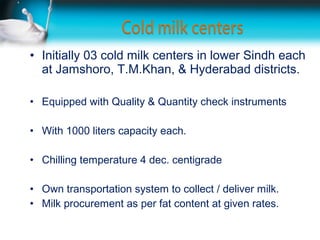

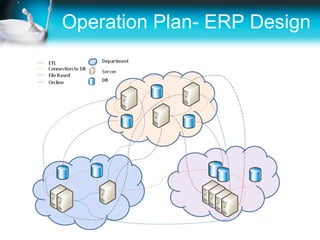

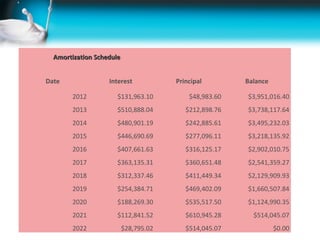

The document outlines a proposal for establishing cold milk centers in Sindh province to address issues with milk availability, quality, and waste by collecting, chilling, and storing milk hygienically to extend its shelf life and ensure a regular supply of pure milk to customers. It discusses the current challenges around milk production and distribution, provides operational details of the proposed centers, and presents financial projections indicating the business will be profitable.