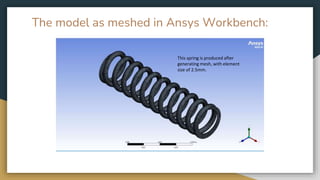

This document summarizes a student project analyzing a helical compression spring using static, modal, and harmonic analysis in FEM. The spring is modeled in Fusion 360 and Ansys Workbench. Static analysis found maximum stress of 8.807e8 Pa and deformation of 0.0269mm under 1667N force. Modal analysis identified the first 8 natural frequencies ranging from 14.54Hz to 193.24Hz. Harmonic analysis from 0.5-80Hz found highest deflection and stress in the inner region. Results showed stresses and deformations within acceptable ranges, and natural frequencies that could cause resonance.