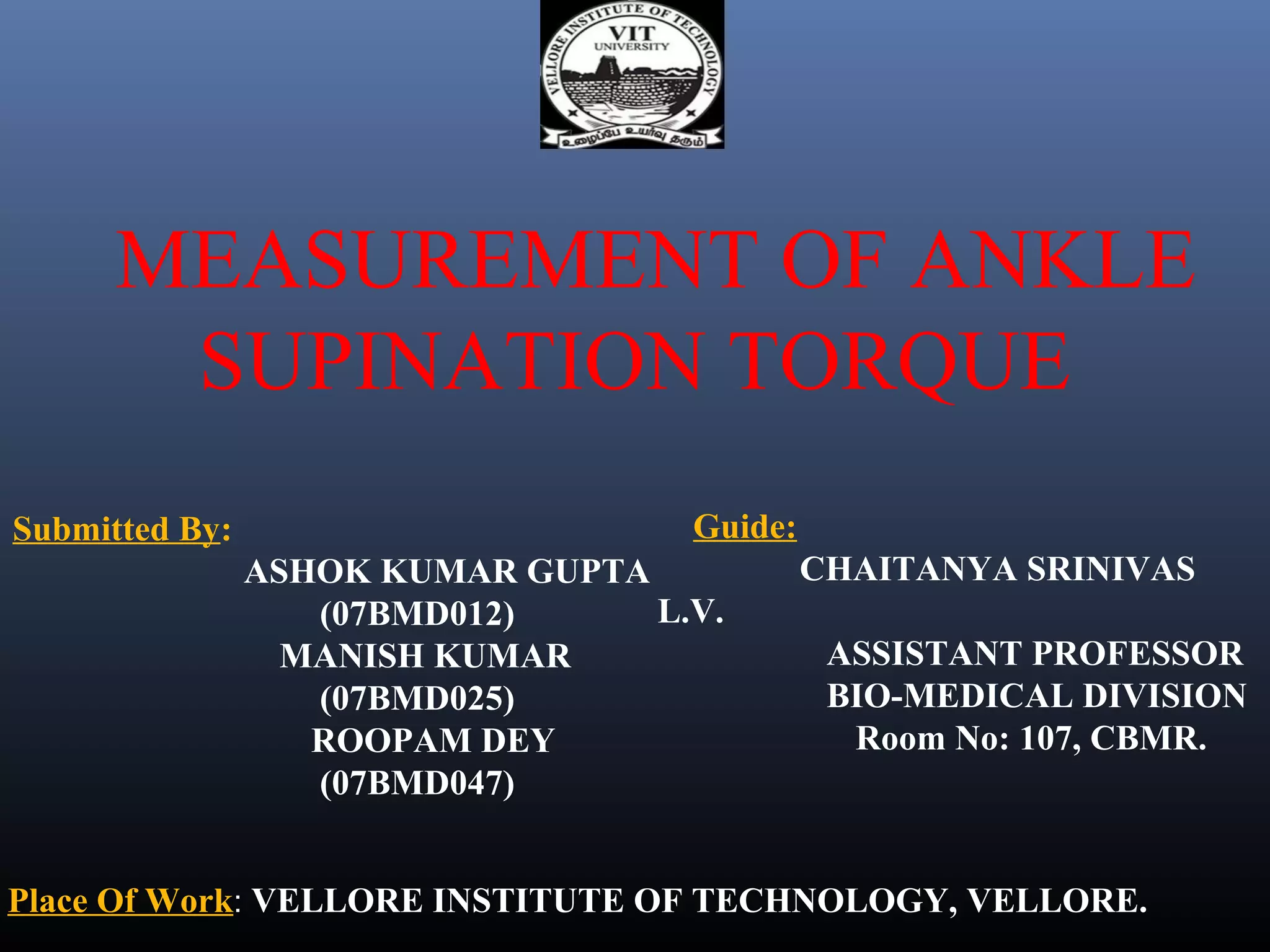

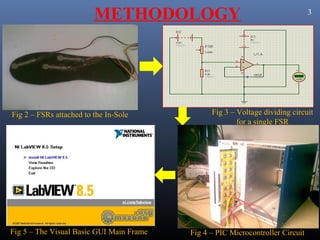

This document describes a project to measure ankle supination torque. Force sensing resistors were attached to an insole and a voltage divider circuit was used to convert pressure readings to electrical signals. The signals were acquired using a data acquisition system and analyzed in LabVIEW. Testing on 4 subjects found increased ankle supination torque when walking in a controlled supinated manner compared to normal walking. The system provides a way to monitor ankle supination torque and help with athlete training.

![PREPARATION 2

The overview of this project was taken from the work done by the

Chinese scientists Daniel Tik-Pui Fong et al[2].

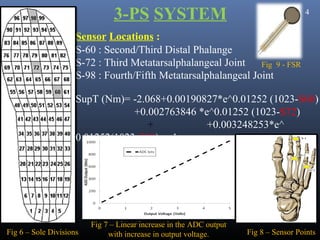

The sensors used by us are Force Sensing Resistors (FSR),

manufactured by Interlink Electronics. The work done by Indian

scientist Dr. N.K. Rana of RGIT[1] helped us to work with the

sensors.

A thorough study of FSR[4]was done that helped us to narrow down

to a voltage-divider circuit using LM 324.

The manual of National Instruments on Lab VIEW Analysis

Concepts[8] gave us the basic idea of signal processing and analysis

in Lab VIEW.

Introduction to Data AcQuisition[9] is the tutorial of National

Instruments that gives the overview of the DAQ and its functions.](https://image.slidesharecdn.com/finalpr-121231004752-phpapp02/85/Measurement-of-Ankle-Supination-Torque-3-320.jpg)

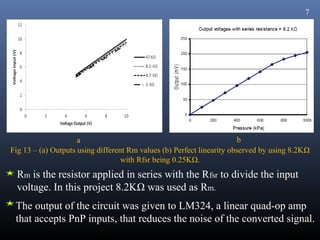

![VOLTAGE DIVIDER CIRCUIT 6

a b

Fig 12 – (a)The theoretical design and (b) the practical output of Voltage Divider Circuit

Vout = Vin * [1 / (1 + Rfsr / Rm ) ]

To convert the pressure of the foot into voltage a voltage divider

circuit was implemented. The above given formula was used.

5V was used as the Vin.](https://image.slidesharecdn.com/finalpr-121231004752-phpapp02/85/Measurement-of-Ankle-Supination-Torque-7-320.jpg)

![REFERENCES 16

[1] Application of Force Sensing Resistor (FSR) in Design of Pressure Scanning System for

Plantar Pressure Measurement

By: Dr. N. K. Rana, Department of Instrumentation Engineering, Rajiv Gandhi Institute of

Technology

[2] A three-pressure-sensor (3PS) system for monitoring ankle supination torque during sport

motions

By: Daniel Tik-Pui Fong, Yue-Yan Chan, Youlian Hong, Patrick Shu-Hang Yung, Kwai-Yau

Fung, Kai-Ming Chan

[3] LM 324 Datasheet

By- Phillips Electronics

[4] FSR an Overview of the technology

By- Tech Storm Inc

[5] MAX 232 Datasheet

By- Texas Instruments

[6] PIC 16F873 Datasheet

By- Microchip

[7] 3-Terminal 1A Positive Voltage Regulator

By- FAIRCHILD SEMICONDUCTORS

[8] Lab VIEW Analysis and Concepts

By- National Instruments

[9] Introduction to Data Acquisition

By- National Instruments](https://image.slidesharecdn.com/finalpr-121231004752-phpapp02/85/Measurement-of-Ankle-Supination-Torque-17-320.jpg)