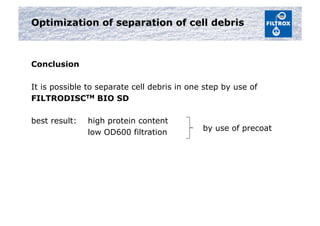

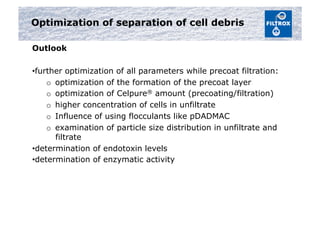

The document summarizes optimization work done using FILTROX's FILTRODISCTM BIO SD filtration system to separate cell debris from recombinant E. coli fermentation broth. Key findings include: (1) Precoat filtration using diatomaceous earth filter aid Celpure® C65 achieved the lowest turbidity in filtrate; (2) Increasing precoat concentration and volume further reduced turbidity; (3) Precoat filtration allowed high protein passage while effectively retaining cell debris. Further work may optimize precoat formation and examine particle size distribution and endotoxin levels.

![Optimization of separation of cell debris

Filtration

number

Filter sheet

type

Filter aid type OD600 [-]

2 CH 73P Celpure® C300 0.118

6 CH 73P Celpure® C100 0.075

4 CH 73P Celpure® C65 0.056

Conclusion:

Celpure® C65 gave the lowest turbidity content

Selection of filter aid](https://image.slidesharecdn.com/filtrox2016berlin-160308123036/85/Filtrox-BILS-2016-11-320.jpg)

![Optimization of separation of cell debris

Selection of filter sheet type

Filtration

number

Filter

sheet type

Retention

rate [µ]

OD600 [-]

10 CH 103P 1.5 – 0.6 0.183

16 CH 143P 0.4 – 0.2 0.111

17 CH 153P 0.2 – 0.04 0.107

For further trials filter sheet type CH 103P and

Celpure® C65 was chosen.

Questions:

- reduction of OD by

1. increasing concentration of filter aid?

2. use of precoat filtration

3. use of flocculants](https://image.slidesharecdn.com/filtrox2016berlin-160308123036/85/Filtrox-BILS-2016-12-320.jpg)

![Optimization of separation of cell debris

Variation of filter aid concentration

Filtration

number

Cfilter aid [g/l] OD600 [-]

8 25 0.0435

13 37.5 0.0445

Celpure® C65 and

CH 103P are used](https://image.slidesharecdn.com/filtrox2016berlin-160308123036/85/Filtrox-BILS-2016-13-320.jpg)

![Optimization of separation of cell debris

Precoat filtration

Precoat and

filtration are done

with Celpure® C65,

CH 103P is used as

filter sheet type

Filtration Cfilter aid [g/L] OD600 [-]

precoating filtration

8 - 25 0,044

12 12,5 25 0,013](https://image.slidesharecdn.com/filtrox2016berlin-160308123036/85/Filtrox-BILS-2016-14-320.jpg)

![Optimization of separation of cell debris

Precoat filtration

Celpure® C65 and

CH 103P are used

Filtration Vprecoating[mL] Cfilter aid [g/L] OD600

precoating filtration

8 - - 25 0,0435

11 200 25 25 0,013

18 400 25 25 0,004](https://image.slidesharecdn.com/filtrox2016berlin-160308123036/85/Filtrox-BILS-2016-16-320.jpg)

![Optimization of separation of cell debris

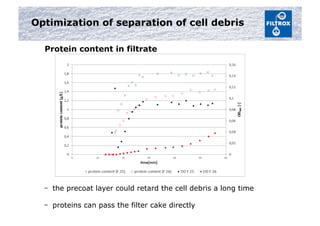

Protein content in filtrate

For the separation it is important to:

- reduce the turbidity of the filtrate by retention of the

cell debris

- ensure the unhindered passing of the proteins

through the precoat layer

Comparison of body feed filtration and precoat

filtration (concerning the protein concentration)

Filtration Cfilter aid [g/L] Vprecoating[mL] Vfiltration[mL]

Precoating Filtration

25 - 25 - 400

26 12,5 25 400 400](https://image.slidesharecdn.com/filtrox2016berlin-160308123036/85/Filtrox-BILS-2016-18-320.jpg)