This document discusses challenges in predictive data analytics for biopharmaceutical process and product development. It notes that process and analytical variability exists between laboratory, pilot, and production scales. Predictive modeling and data fusion techniques can help address this variability and improve quality across scales by integrating product and process development. Case studies will demonstrate these approaches for fermentation processes.

![Process and Analytical Variability Challenges

‘Product Quality’ across lab, pilot & production scales

(Staffan Folestad AstraZeneca, APACT09)

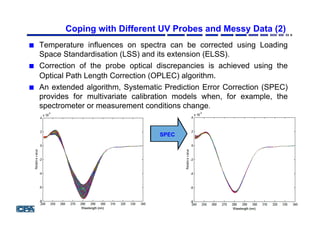

Spectra from different probes

show distinct Inter-probe variability

Position 1

P 2

P3

P4

-20

-10

0

10

20

t[2]

t[1]

•P1-2225.0

•P1-

•P1-2303.0•P1-2322.0

•P1-2343.0

•P1-2401.0

•P1-2420.0

•P1-2552.0

•P1-2611.0

•P1-2534.0•P1-2648.0

•P1-2710.0

•P1-2728.0

•P1-2629.0

•P1-2842.0

•P1-2919.0

•P1-2746.0•P1-2805.0

•P1-2823.0•P1-2900.0

•P1-3014.0

•P1-3245.0•P1-3131.0

•P1-3726.0

•P1-3341.0

•P1-3418.0

•P1-2956.0

•P1-3304.0

•P1-3150.0

•P1-3208.0

•P1-3840.0•P1-3744.0

•P1-3803.0

•P1-4628.0

•P1-3437.0

•P1-3455.0

•P1-3514.0

•P1-3400.0

•P1-3708.0

•P1-3227.0

•P1-4225.0

•P1-4244.0

•P1-3859.0

•P1-4015.0

•P1-4609.0

•P1-4646.0

•P1-4514.0

•P1-4551.0

•P1-4819.0

•P1-4837.0

•P1-4705.0

•P1-4723.0

•P1-4742.0

•P1-3532.0

•P1-4532.0

•P1-4800.0

•P2-5400.0

•P2-5537.0

•P2-5746.0

•P2-5708.0

•P2-5919.0

•P2-5937.0

•P2-5900.0

•P2-0033.0

•P2-5805.0•P2-5507.0

•P2-5440.0

•P2-5420.0

•P2-5610.0

•P2-5727.0

•P2-5629.0

•P2-5649.0

•P2-0150.0

•P2-0245.0

•P2-2053.0

•P2-0707.0

•P2-0630.0

•P2-0612.0

•P2-0322.0

•P2-0208.0

•P2-0227.0

•P2-0437.0

•P2-0418.0

•P2-1440.0•P2-1147.0

•P2-2206.0

•P2-2111.0

•P2-2225.0

•P2-2342.0•P2-2244.0•P2-1806.0

•P2-1727.0•P2-1939.0

•P2-0649.0

•P2-0553.0•P2-0725.0

•P2-0839.0

•P2-0821.0

•P2-0744.0•P2-0803.0

•P2-0534.0

•P2-0304.0

•P2-0359.0

•P2-1421.0

•P2-1206.0•P2-1129.0

•P2-1650.0•P2-2148.0

•P2-2129.0

•P2-2400.0•P2-2323.0

•P2-2305.0•P2-2034.0

•P2-1825.0

•P2-1748.0

•P2-1708.0

•P2-1843.0

•P2-1957.0•P2-2015.0

•P2-1902.0

•P2-1920.0

•P2-0916.0

•P2-0858.0

•P4-2006.0

•P4-2348.0

•P4-1849.0

•P4-1658.0

•P4-1409.0•P4-1427.0

•P4-1331.0

•P4-1254.0

•P4-1313.0•P4-1603.0•P4-1621.0

•P4-1640.0

•P4-3040.0

•P4-2311.0

•P4-2253.0•P4-2157.0

•P4-2216.0

•P4-2234.0

•P4-2600.0

•P4-2427.0

•P4-2446.0

•P4-1217.0

•P4-1831.0

•P4-1350.0

•P4-1236.0

•P4-1544.0

•P4-2945.0

•P4-2849.0

•P4-2908.0

•P4-2926.0

•P4-2619.0

•P4-2330.0

•P4-2523.0

•P4-2542.0

•P4-2504.0•P4-2409.0

•P3-4438.0

•P3-5058.0•P3-5019.0

•P3-4941.0

•P3-5232.0

•P3-5154.0

•P3-5117.0

•P3-5135.0

•P3-4650.0

•P3-4631.0•P3-4845.0

•P4-0158.0

•P4-0220.0•P4-0238.0

•P3-4242.0

•P3-4516.0

•P3-4535.0

•P3-4457.0

•P3-4127.0

•P3-4050.0

•P3-5038.0

•P3-5000.0

•P3-5213.0

•P3-4922.0•P3-4708.0

•P3-4730.0

•P3-4612.0

•P3-3137.0

•P3-3640.0

•P3-3701.0

•P3-3621.0

•P3-3835.0

•P3-3446.0

•P3-3505.0

•P3-3427.0

•P3-3350.0

•P3-3408.0

•P4-0026.0

•P4-0140.0

•P4-0044.0

•P3-4340.0

•P3-4321.0•P3-4301.0

•P3-4420.0

•P3-4109.0

•P3-4554.0

•P3-3002.0

•P3-2921.0

•P3-3118.0

•P3-3059.0

•P3-3020.0

•P3-3039.0

•P3-3155.0

•P3-3544.0

•P3-3603.0•P3-3816.0

•P3-3233.0

•P4-0007.0•P4-5912.0

•P3-4401.0

•P3-2940.0

•P3-2844.0

•P3-2902.0

•P4-5949.0

•P4-5931.0

•P4-5854.0

•P3-2748.0

•P3-2806.0

•P3-2729.0

•P3-2710.0

•P4-5835.0

•P3-2651.0

-100 -80 -60 -40 -20 0 20 40 60 80 100

P2

P1

Position 1

P 2

P3

P4

-20

-10

0

10

20

t[2]

t[1]

•P1-2225.0

•P1-

•P1-2303.0•P1-2322.0

•P1-2343.0

•P1-2401.0

•P1-2420.0

•P1-2552.0

•P1-2611.0

•P1-2534.0•P1-2648.0

•P1-2710.0

•P1-2728.0

•P1-2629.0

•P1-2842.0

•P1-2919.0

•P1-2746.0•P1-2805.0

•P1-2823.0•P1-2900.0

•P1-3014.0

•P1-3245.0•P1-3131.0

•P1-3726.0

•P1-3341.0

•P1-3418.0

•P1-2956.0

•P1-3304.0

•P1-3150.0

•P1-3208.0

•P1-3840.0•P1-3744.0

•P1-3803.0

•P1-4628.0

•P1-3437.0

•P1-3455.0

•P1-3514.0

•P1-3400.0

•P1-3708.0

•P1-3227.0

•P1-4225.0

•P1-4244.0

•P1-3859.0

•P1-4015.0

•P1-4609.0

•P1-4646.0

•P1-4514.0

•P1-4551.0

•P1-4819.0

•P1-4837.0

•P1-4705.0

•P1-4723.0

•P1-4742.0

•P1-3532.0

•P1-4532.0

•P1-4800.0

•P2-5400.0

•P2-5537.0

•P2-5746.0

•P2-5708.0

•P2-5919.0

•P2-5937.0

•P2-5900.0

•P2-0033.0

•P2-5805.0•P2-5507.0

•P2-5440.0

•P2-5420.0

•P2-5610.0

•P2-5727.0

•P2-5629.0

•P2-5649.0

•P2-0150.0

•P2-0245.0

•P2-2053.0

•P2-0707.0

•P2-0630.0

•P2-0612.0

•P2-0322.0

•P2-0208.0

•P2-0227.0

•P2-0437.0

•P2-0418.0

•P2-1440.0•P2-1147.0

•P2-2206.0

•P2-2111.0

•P2-2225.0

•P2-2342.0•P2-2244.0•P2-1806.0

•P2-1727.0•P2-1939.0

•P2-0649.0

•P2-0553.0•P2-0725.0

•P2-0839.0

•P2-0821.0

•P2-0744.0•P2-0803.0

•P2-0534.0

•P2-0304.0

•P2-0359.0

•P2-1421.0

•P2-1206.0•P2-1129.0

•P2-1650.0•P2-2148.0

•P2-2129.0

•P2-2400.0•P2-2323.0

•P2-2305.0•P2-2034.0

•P2-1825.0

•P2-1748.0

•P2-1708.0

•P2-1843.0

•P2-1957.0•P2-2015.0

•P2-1902.0

•P2-1920.0

•P2-0916.0

•P2-0858.0

•P4-2006.0

•P4-2348.0

•P4-1849.0

•P4-1658.0

•P4-1409.0•P4-1427.0

•P4-1331.0

•P4-1254.0

•P4-1313.0•P4-1603.0•P4-1621.0

•P4-1640.0

•P4-3040.0

•P4-2311.0

•P4-2253.0•P4-2157.0

•P4-2216.0

•P4-2234.0

•P4-2600.0

•P4-2427.0

•P4-2446.0

•P4-1217.0

•P4-1831.0

•P4-1350.0

•P4-1236.0

•P4-1544.0

•P4-2945.0

•P4-2849.0

•P4-2908.0

•P4-2926.0

•P4-2619.0

•P4-2330.0

•P4-2523.0

•P4-2542.0

•P4-2504.0•P4-2409.0

•P3-4438.0

•P3-5058.0•P3-5019.0

•P3-4941.0

•P3-5232.0

•P3-5154.0

•P3-5117.0

•P3-5135.0

•P3-4650.0

•P3-4631.0•P3-4845.0

•P4-0158.0

•P4-0220.0•P4-0238.0

•P3-4242.0

•P3-4516.0

•P3-4535.0

•P3-4457.0

•P3-4127.0

•P3-4050.0

•P3-5038.0

•P3-5000.0

•P3-5213.0

•P3-4922.0•P3-4708.0

•P3-4730.0

•P3-4612.0

•P3-3137.0

•P3-3640.0

•P3-3701.0

•P3-3621.0

•P3-3835.0

•P3-3446.0

•P3-3505.0

•P3-3427.0

•P3-3350.0

•P3-3408.0

•P4-0026.0

•P4-0140.0

•P4-0044.0

•P3-4340.0

•P3-4321.0•P3-4301.0

•P3-4420.0

•P3-4109.0

•P3-4554.0

•P3-3002.0

•P3-2921.0

•P3-3118.0

•P3-3059.0

•P3-3020.0

•P3-3039.0

•P3-3155.0

•P3-3544.0

•P3-3603.0•P3-3816.0

•P3-3233.0

•P4-0007.0•P4-5912.0

•P3-4401.0

•P3-2940.0

•P3-2844.0

•P3-2902.0

•P4-5949.0

•P4-5931.0

•P4-5854.0

•P3-2748.0

•P3-2806.0

•P3-2729.0

•P3-2710.0

•P4-5835.0

•P3-2651.0

-100 -80 -60 -40 -20 0 20 40 60 80 100

P2

P1

Sensing space direction

PCA of spectra collected for over 1 hr

Courtesy R O’Kennedy et al (GSK & Univ Strathclyde)

Agitator

L1

L2

L3

L4

Probe Location

L2

L3

L4

Probe Location

‘Identical Reactors – Different heat-

transfer characteristics ?’

16m3

35m3

24m3

24m3

24m3

Are

‘Iden)cal

Disposables’

‘Iden)cal?’](https://image.slidesharecdn.com/julianmorisnewcastleppt-160308123212/85/Newcastle-BILS-2016-7-320.jpg)

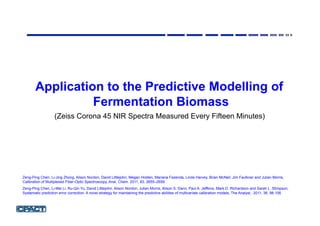

![■ The process under study was an industrial pilot-plant scale

streptomyces fermentation involving a seed stage and a production

stage.

■ Biomass was grown in the seed stage and then transferred into the

final fed batch stage for the production of the product lasting

approximately 140hrs.

■ Two sets of fermentation experiments were carried out. The first set

comprised seven batches (calibration batches); the second set was

made up of six batches (test batches).

■ The seven calibration batches were run under similar conditions, but

natural variation provided some degree of variability.

■ For the test batches, the runs were carried out under different

environmental conditions (pH and temperature), feed rates (sugar

feed) and feed amounts (oil feed).

Coping with Process Variation [Courtesy GSK]](https://image.slidesharecdn.com/julianmorisnewcastleppt-160308123212/85/Newcastle-BILS-2016-23-320.jpg)

![Prediction of Product Concentration [Courtesy GSK]

PLS calibration built using the spectra of the

samples from primary instrument.

Global PLS using the spectra samples from the primary instrument

and six standardisation samples from the secondary instrument

Blue circles - product

concentration by off-line assay

Systematic Prediction Error Correction Algorithm

Stretomyces Fermentation](https://image.slidesharecdn.com/julianmorisnewcastleppt-160308123212/85/Newcastle-BILS-2016-24-320.jpg)