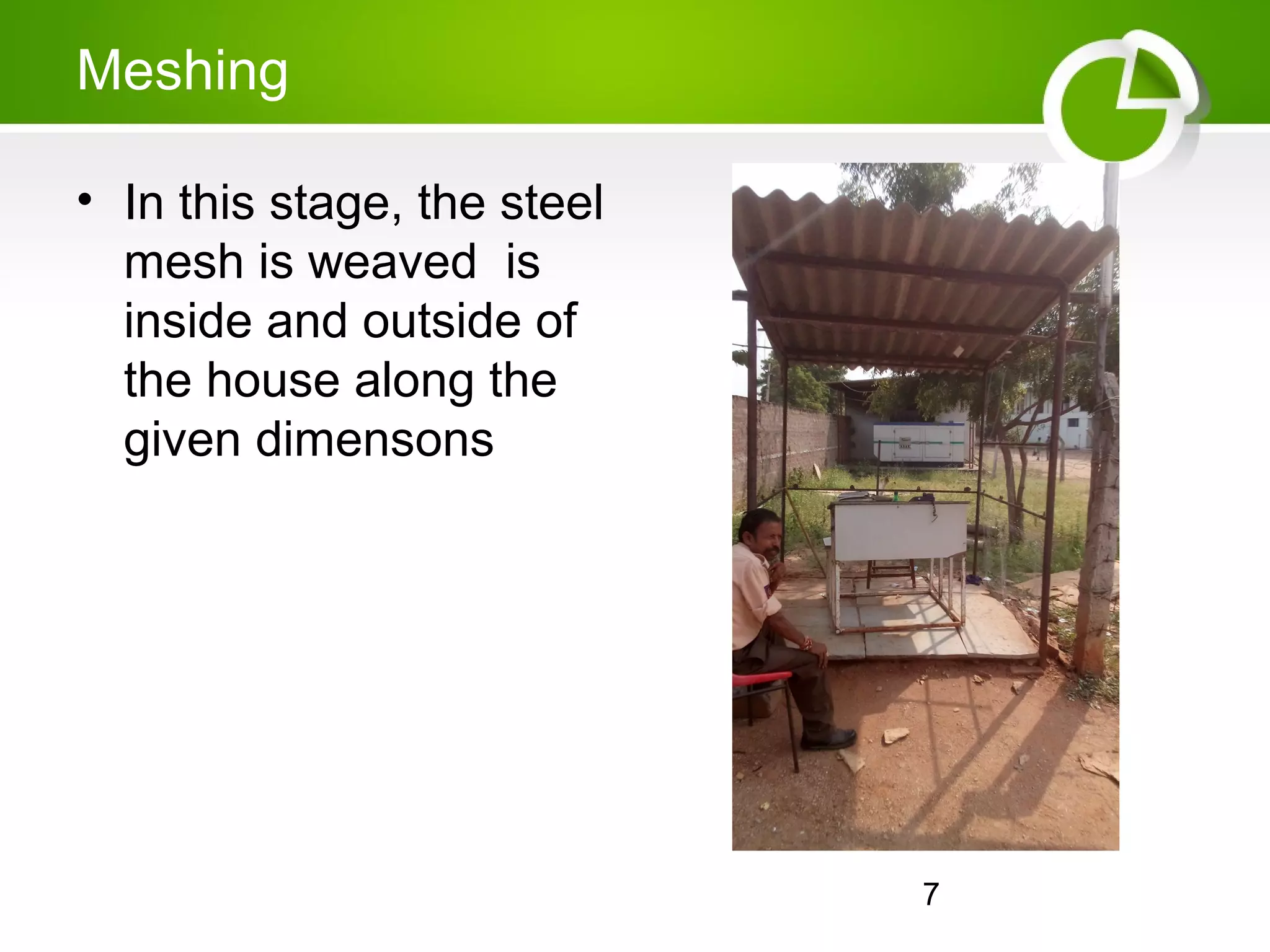

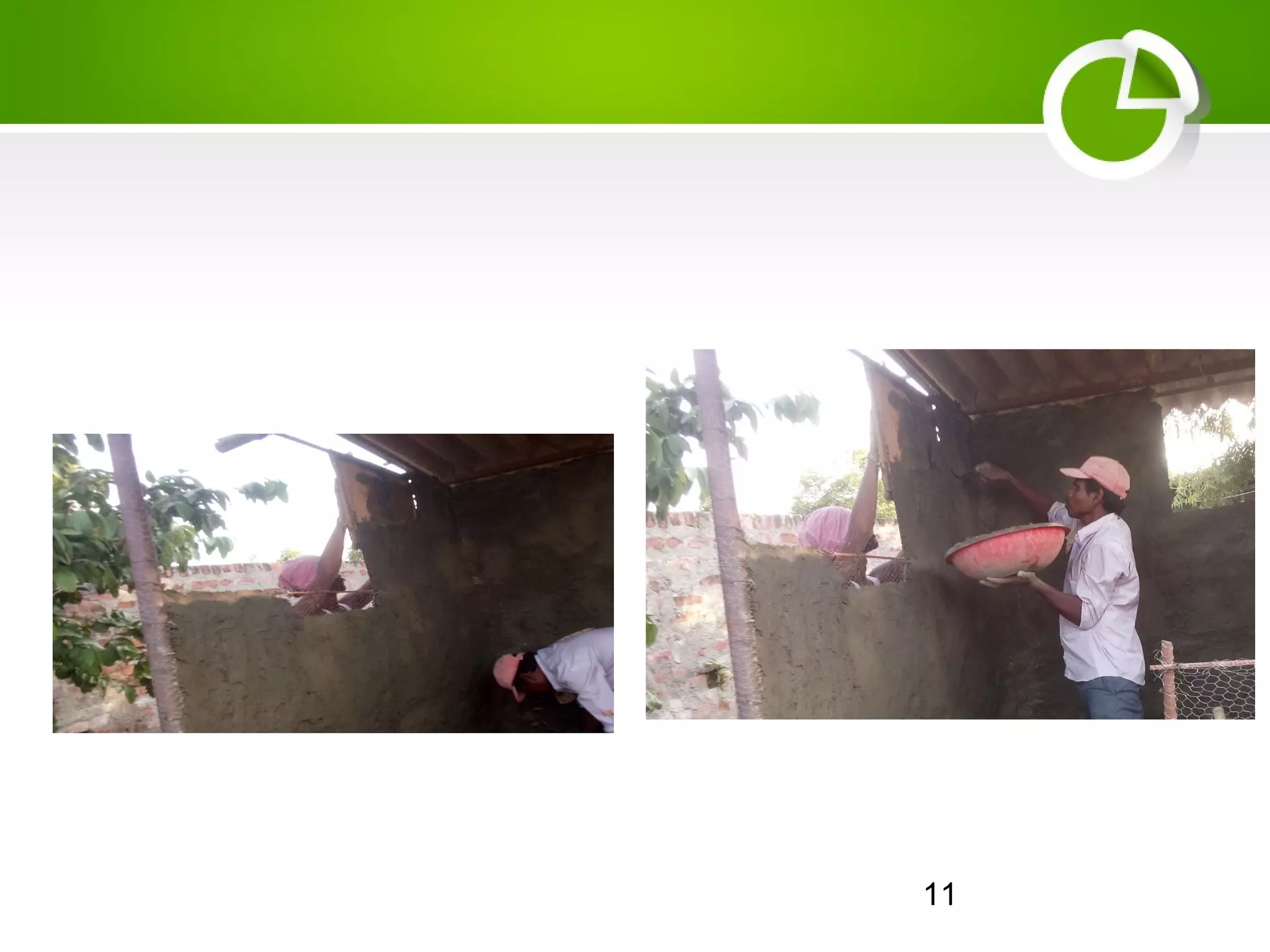

The document details the construction process of a ferrocement house, aimed at providing low-cost housing in rural India using locally available materials. It describes the requirements, dimensions, and materials needed, along with the construction stages including skeleton arrangement, meshing, mortar filling, and plastering. The overall cost for constructing a house measuring 6.3ft x 6ft x 7.9ft is estimated at ₹10,000, which is about 20% less than conventional methods.