The document discusses several alternate wall technologies:

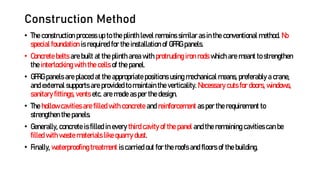

- Glass Fiber Reinforced Gypsum Panels (GFRG) which are strong load-bearing panels made of gypsum reinforced with glass fiber. They provide more floor space and lower construction costs than conventional methods.

- Concrete Insulated Walls which use insulating concrete forms that are filled with concrete to create strong, energy efficient walls.

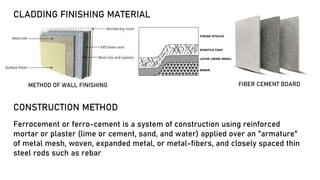

- Ferrocement walls which are a type of thin reinforced concrete wall reinforced with layers of wire mesh and rebar that saves on materials.

- Straw bale walls which provide excellent insulation using straw bales stacked and plastered over for a renewable and low-impact building material.

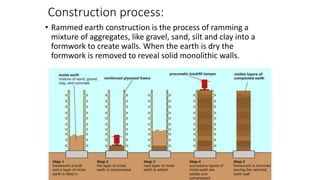

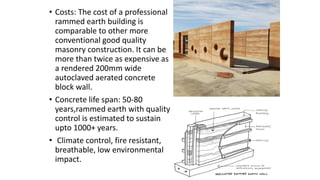

- Rammed earth walls constructed by compact