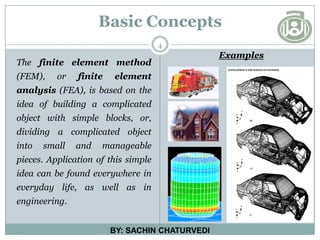

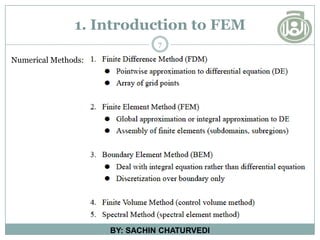

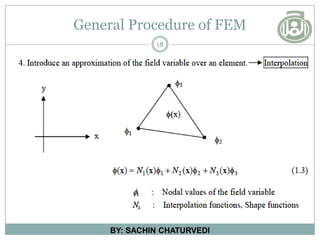

This document provides an introduction to the finite element method (FEM) for mechanical engineering students. It discusses basic FEM concepts and procedures, including dividing complex objects into simple elements, applicable engineering domains, and the general FEM procedure of preprocessing, solving, and postprocessing. Example applications in areas like structural analysis, thermal/fluid analysis, and manufacturing processes are presented. Shape functions and common element types used in FEM are also introduced.