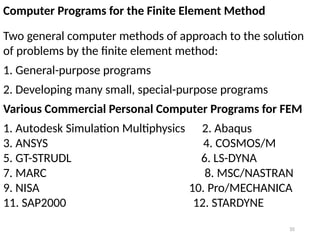

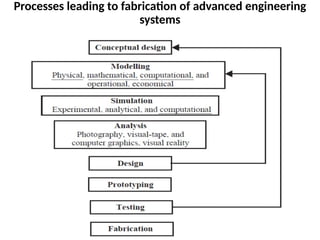

This document serves as an introduction to the finite element method (FEM), covering its background, applications, and key steps in its application. FEM is a numerical technique for solving engineering and mathematical physics problems, particularly those governed by boundary value problems. The document outlines the advantages of FEM, the role of computers in its execution, and various methods used to derive finite element equations.

![11

Introduction to Matrix Notation

• Matrix notation represents a simple system for writing and

solving sets of simultaneous algebraic equations.

• Matrix – a rectangular array of quantities arranged in rows

and columns that is used to express and solve a system of

equations.

• A rectangular matrix is indicated by square bracket notation

[ ].

• A column matrix is indicated by brace notation { }](https://image.slidesharecdn.com/ch-1-241102121438-db47002f/85/chapter-1-introduction-to-finite-element-method-11-320.jpg)

![13

Rectangular matrices

• Here are square matrices, a type of rectangular matrices.

• The first [k] is the element stiffness matrix and the second

[K] is the global stiffness matrix](https://image.slidesharecdn.com/ch-1-241102121438-db47002f/85/chapter-1-introduction-to-finite-element-method-13-320.jpg)

![27

Step 4: Derive the Element Stiffness Matrix Equations

• These equations can be written in matrix form as:

• Or in compact matrix form as

Where {f} is the vector of element nodal forces, [k] is the

element stiffness matrix, and {d} is the vector of unknown

element nodal degrees of freedom](https://image.slidesharecdn.com/ch-1-241102121438-db47002f/85/chapter-1-introduction-to-finite-element-method-27-320.jpg)

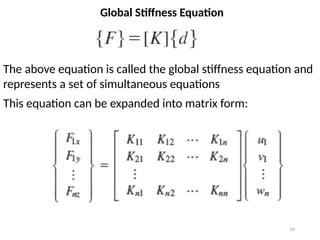

![28

Step 5: Assemble the Element Equations

• The individual element nodal equilibrium equations

generated in step 4 are assembled into the global nodal

equilibrium equations

• The final assembled or global equation is written in matrix

form as:

• Where {F} is the vector of global nodal forces, [K] is the

structure global stiffness matrix, and {d} is now the vector of

known and unknown structure nodal degree of freedom

• Boundary conditions must be invoked to remove the

singularity problem of the global stiffness matrix [K]](https://image.slidesharecdn.com/ch-1-241102121438-db47002f/85/chapter-1-introduction-to-finite-element-method-28-320.jpg)