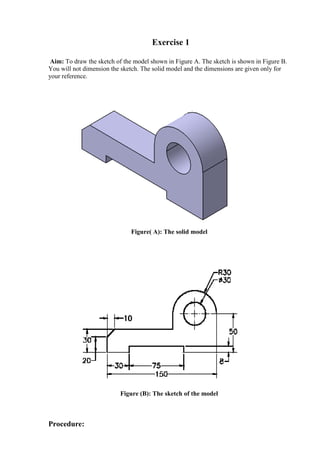

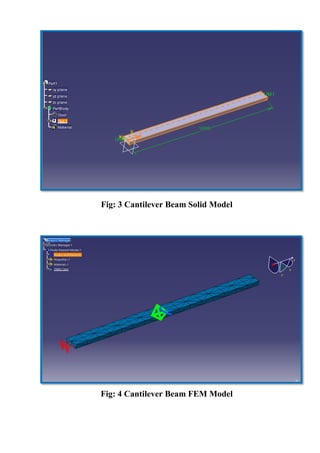

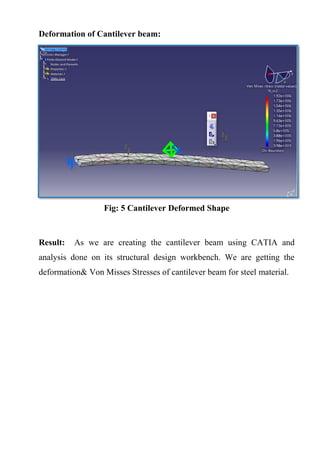

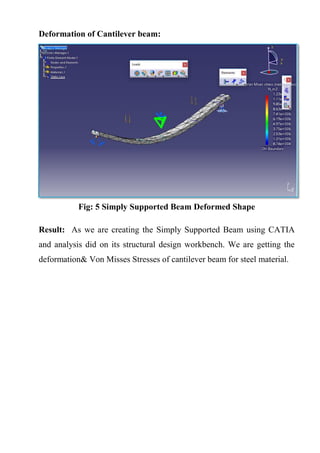

This document provides instructions for five experiments involving finite element analysis using CATIA V5 software. Experiment 1 introduces finite element analysis concepts. Experiment 2 covers solid modeling in CATIA. Experiments 3-5 provide step-by-step instructions for designing and analyzing a cantilever beam, simply supported beam, and bent pipe model. The experiments involve using CATIA workbenches for sketching, part design, meshing, and structural analysis to obtain deformed shapes and von Mises stress results.