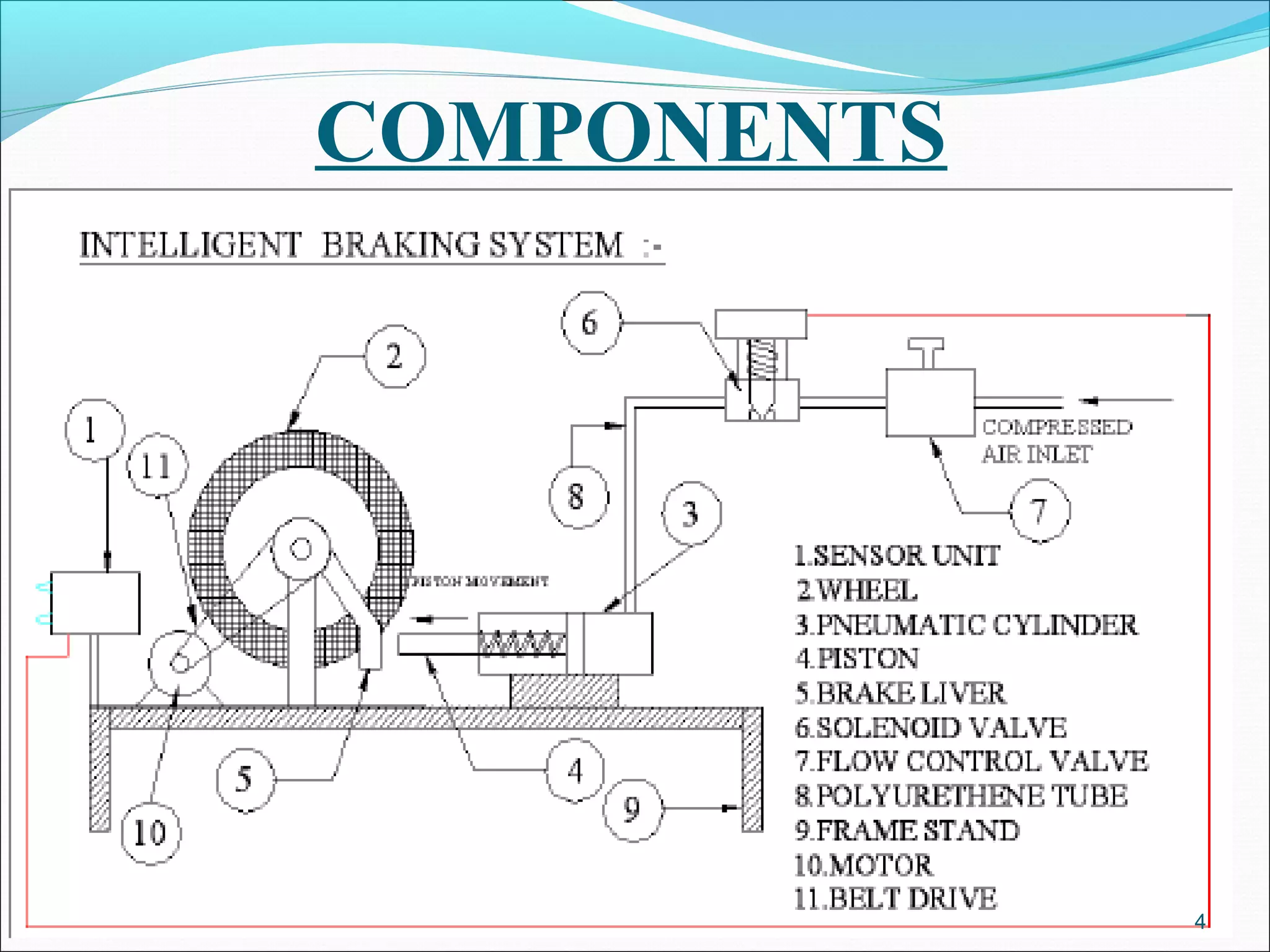

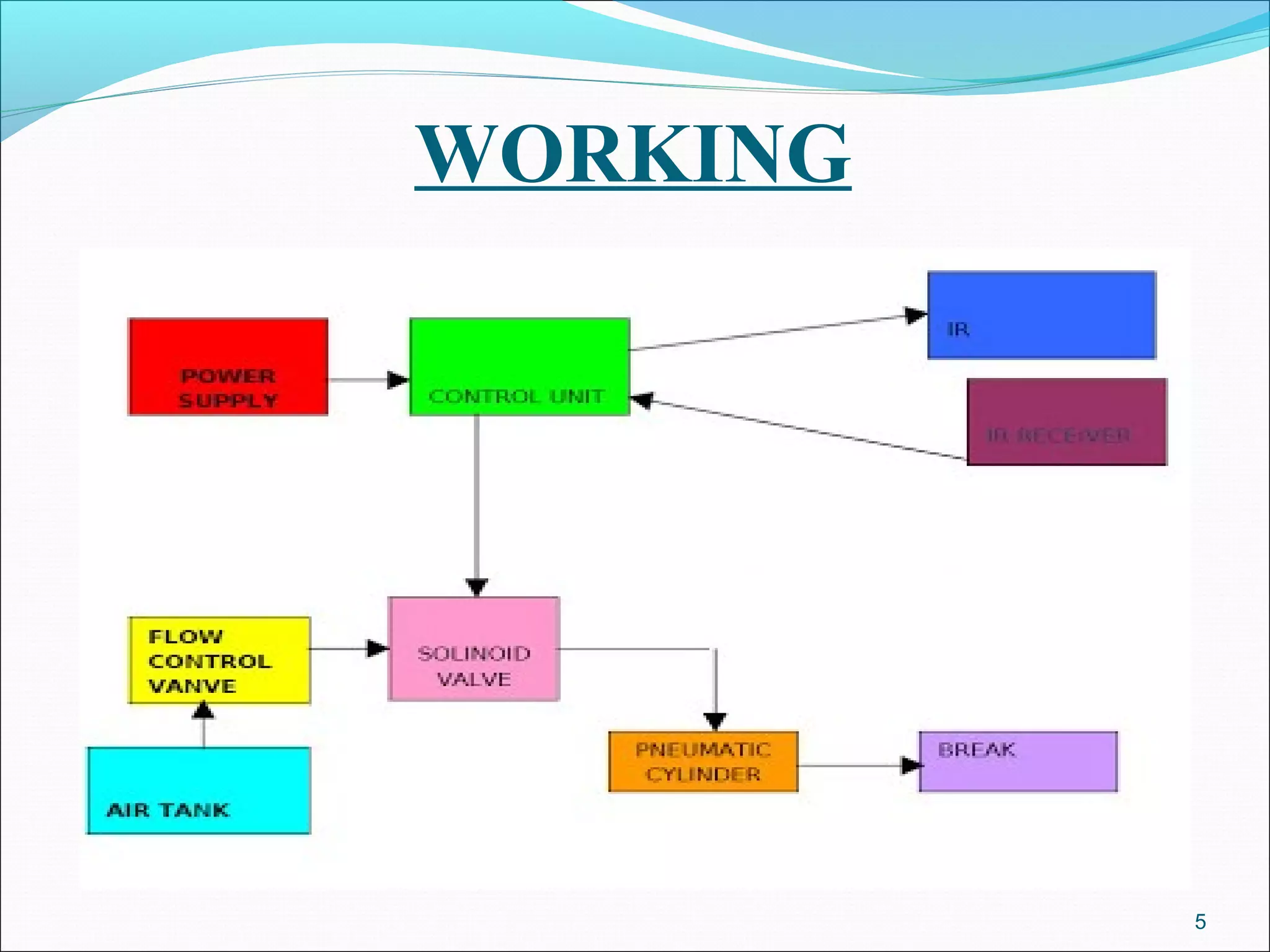

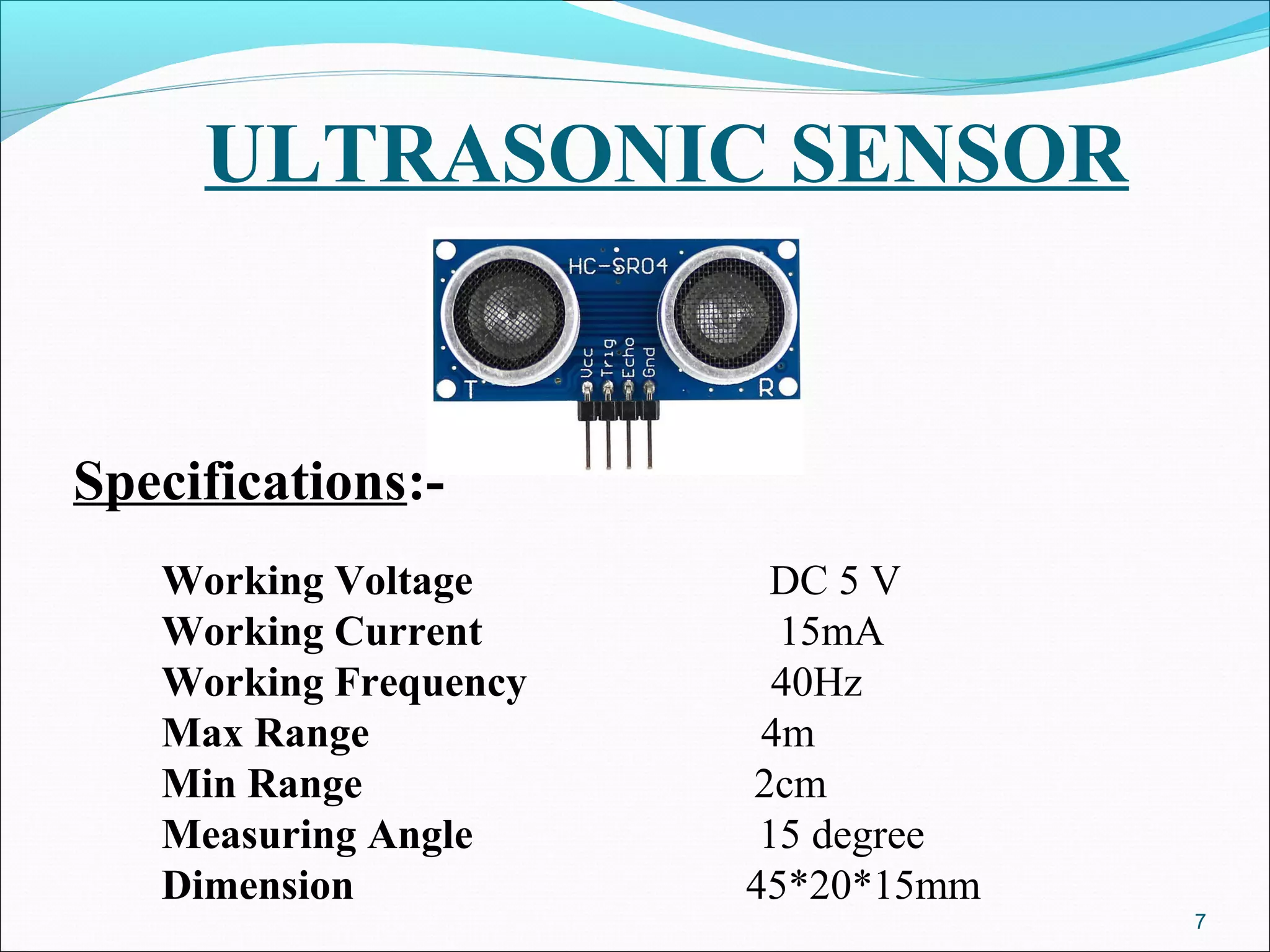

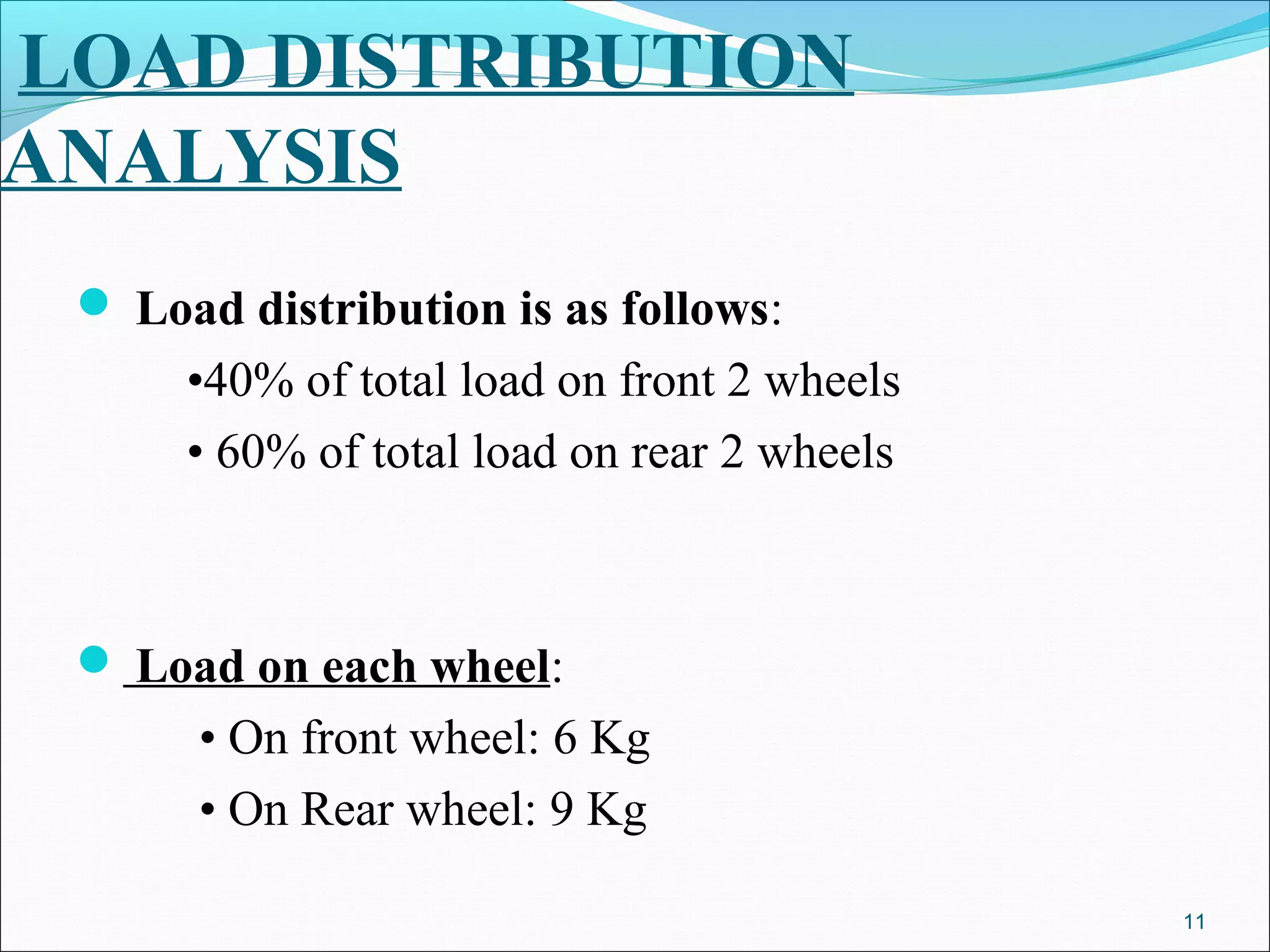

This document describes an intelligent braking system that automatically applies the brakes when a vehicle is in reverse. The key components are an ultrasonic sensor to detect obstacles, a solenoid valve to control air flow, a pneumatic cylinder to apply the brakes, and a pneumatic braking system. When the sensor detects an obstacle behind the vehicle, it sends a signal to open the solenoid valve, allowing air to flow to the cylinder and engage the brakes. Mathematical models are presented to analyze load distribution, weight transfer, clamping force, and required deceleration. The system provides automatic and safe braking when reversing, reducing risk of collisions. Potential applications include automatic parking systems and vehicles generally.