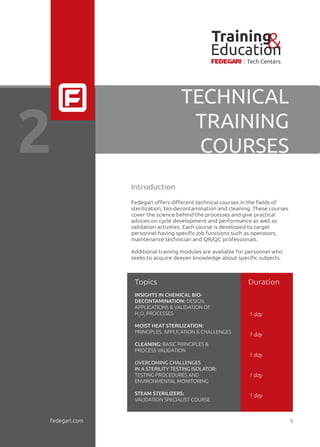

Fedegari is enhancing pharmaceutical manufacturing through innovative solutions and collaboration with strategic partners like universities and technology companies. They offer a comprehensive 2017 training calendar at their tech centers in the USA, Italy, and the UK, focusing on sterilization processes and validations. These customized training programs aim to increase efficiency and effectiveness in the pharmaceutical industry by addressing specific needs in technology and process understanding.