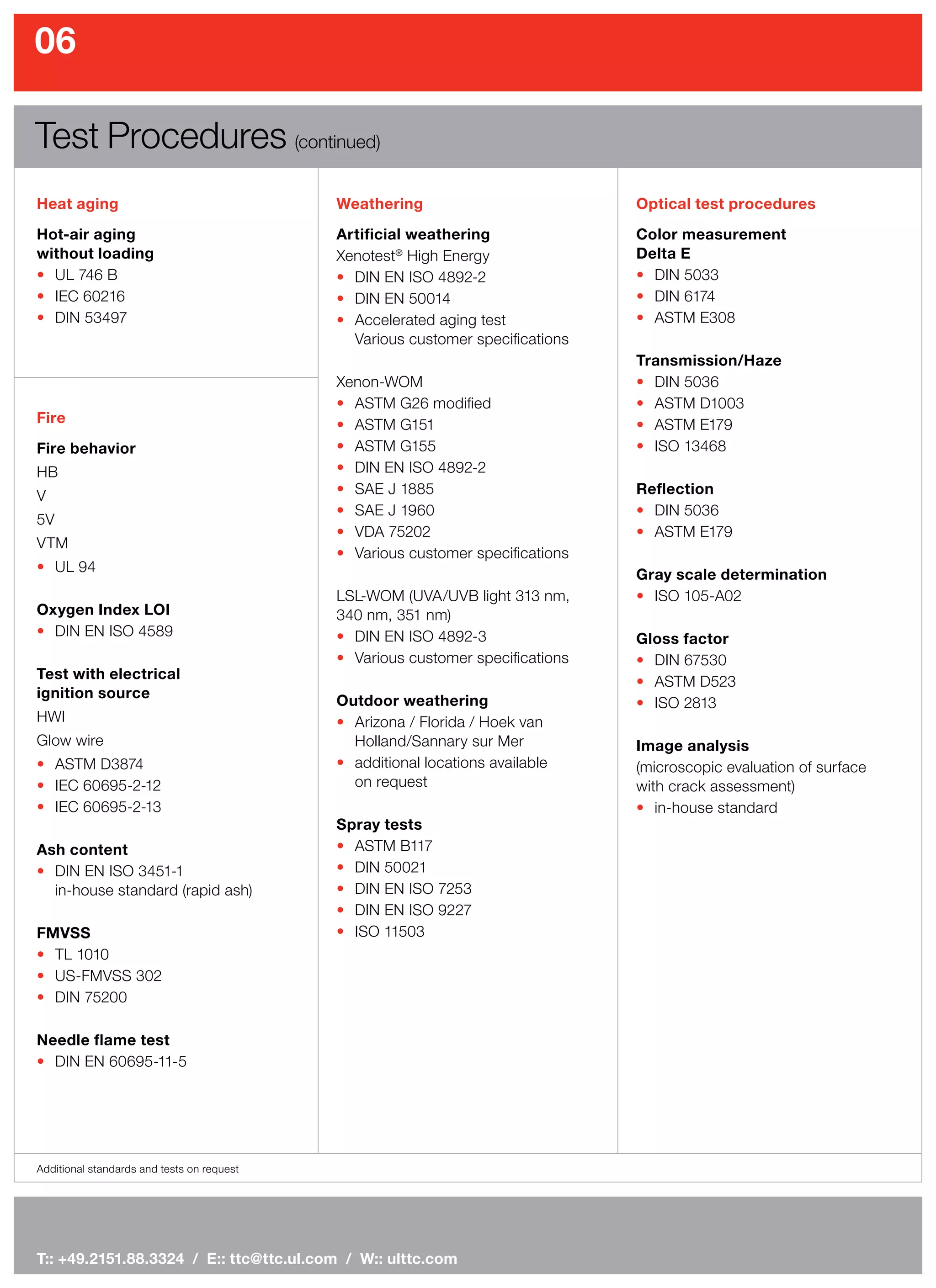

The UL Thermoplastics Testing Center (TTC) provides thermoplastics testing services to help companies speed up product development and get to market faster. It has various capabilities including automated compounding, production of test specimens, over 200 plastic tests, and expertise from 60+ years of experience. The facility uses advanced technology like LIMS software to accelerate the entire testing process from order entry to results. It aims to reduce clients' time and costs through its unmatched capacity, uncompromising quality adherence to standards, and extensive expertise.