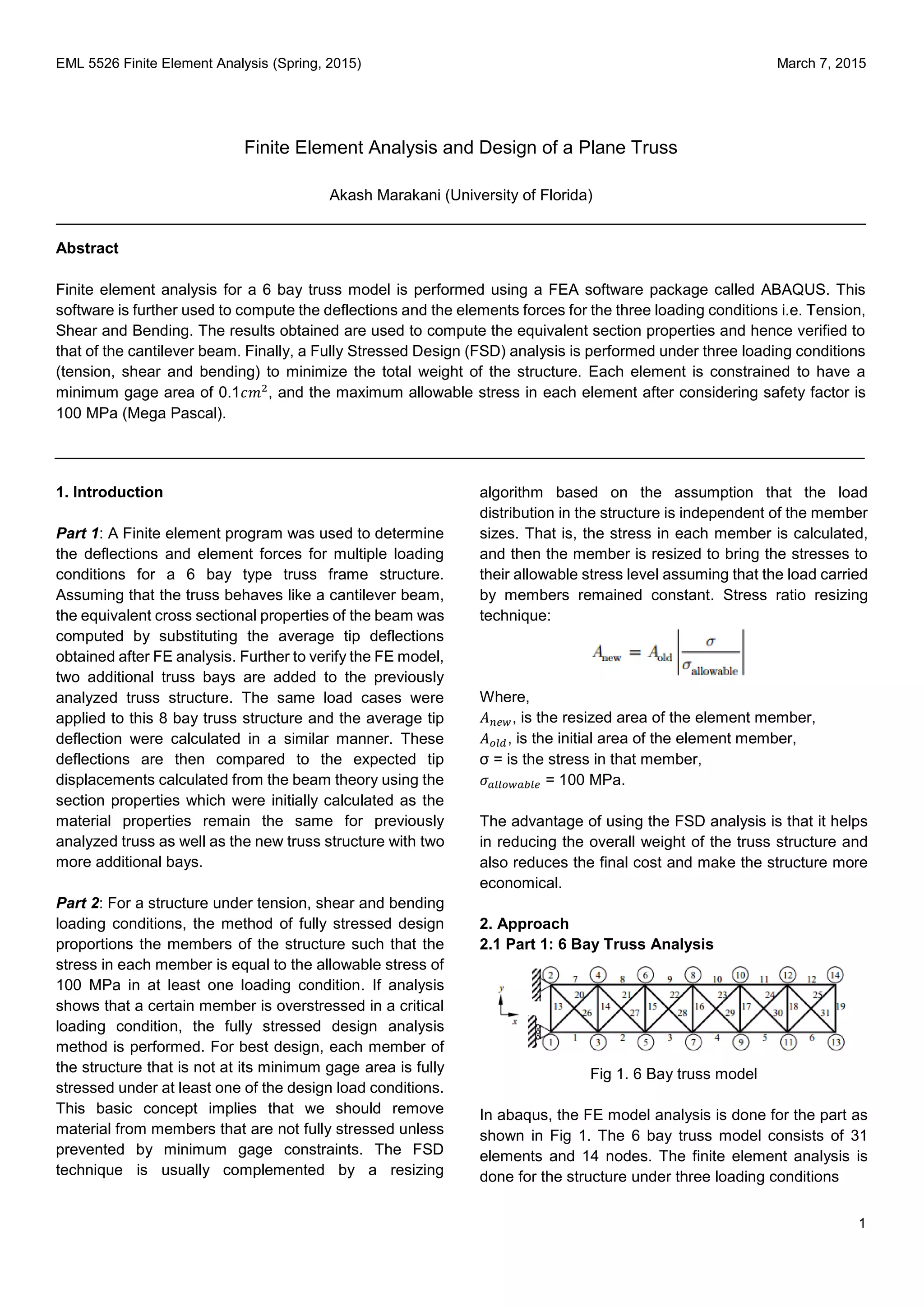

A finite element analysis was performed on a 6 bay plane truss structure using ABAQUS software to determine deflections and member forces under tension, shear, and bending loads. The results were used to calculate equivalent cross-sectional properties, assuming the truss behaved like a cantilever beam. Additional analysis was conducted using fully stressed design to minimize the structure's weight by resizing members to be fully stressed at their allowable limit of 100 MPa under at least one load case, while maintaining a minimum gauge of 0.1 cm^2. Iterative resizing reduced member areas and increased stresses until all members were fully stressed at their limits.