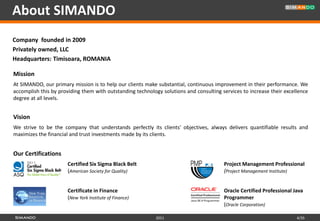

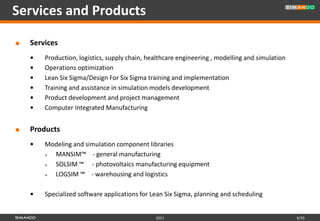

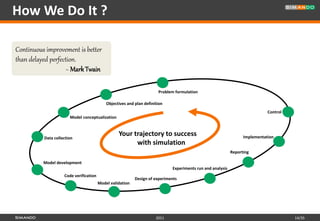

SIMANDO is a global management and technology consulting firm focused on decision support systems and operational excellence. They partner with clients in all industrial sectors to address challenges and develop complete solutions that enable achieving objectives and significant performance improvements. SIMANDO's customized approach combines innovative technology, systems thinking, and passion for operational excellence to ensure their solutions provide sustainable competitive advantage through optimized operations and responsiveness to changing business environments.