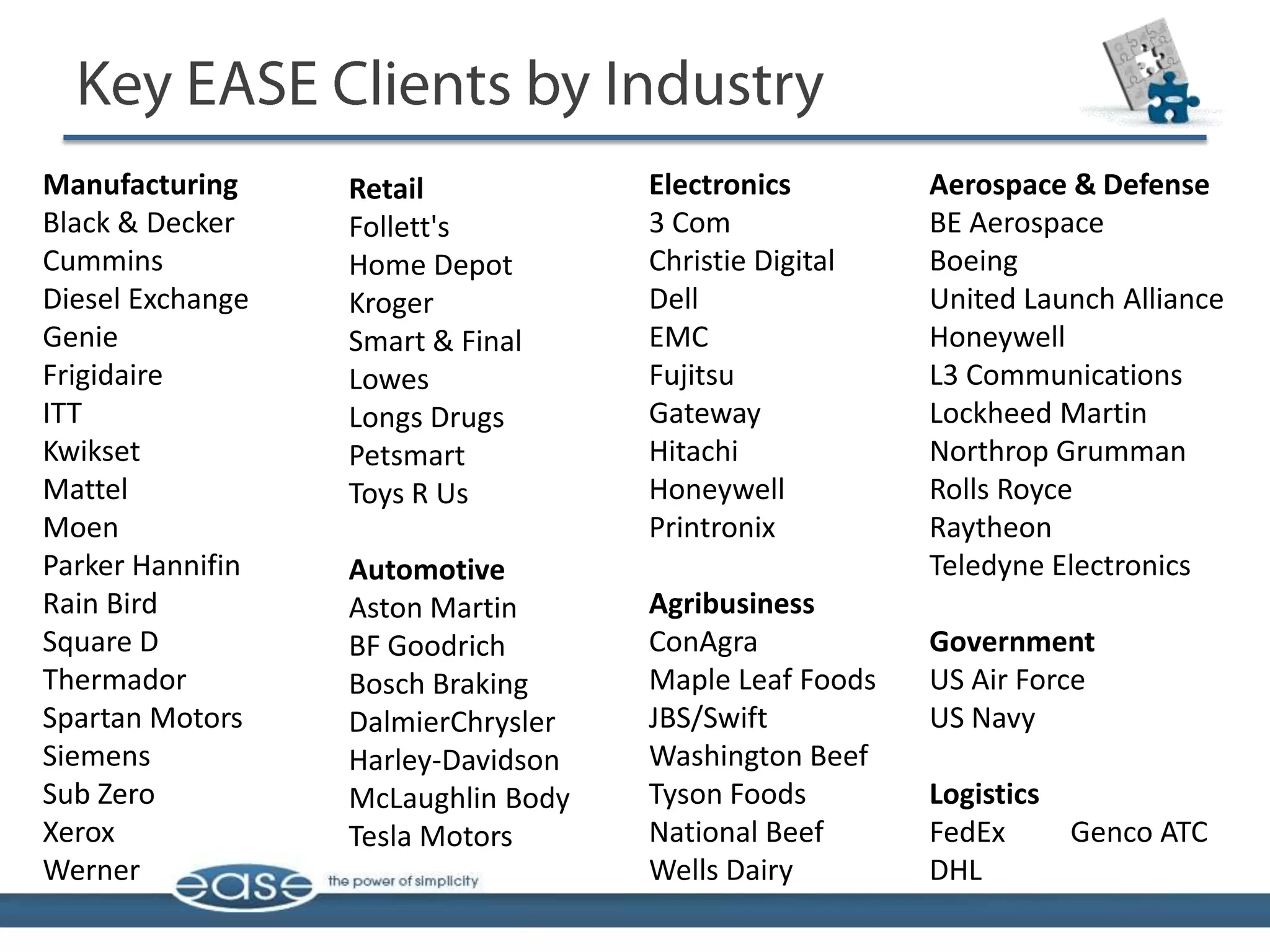

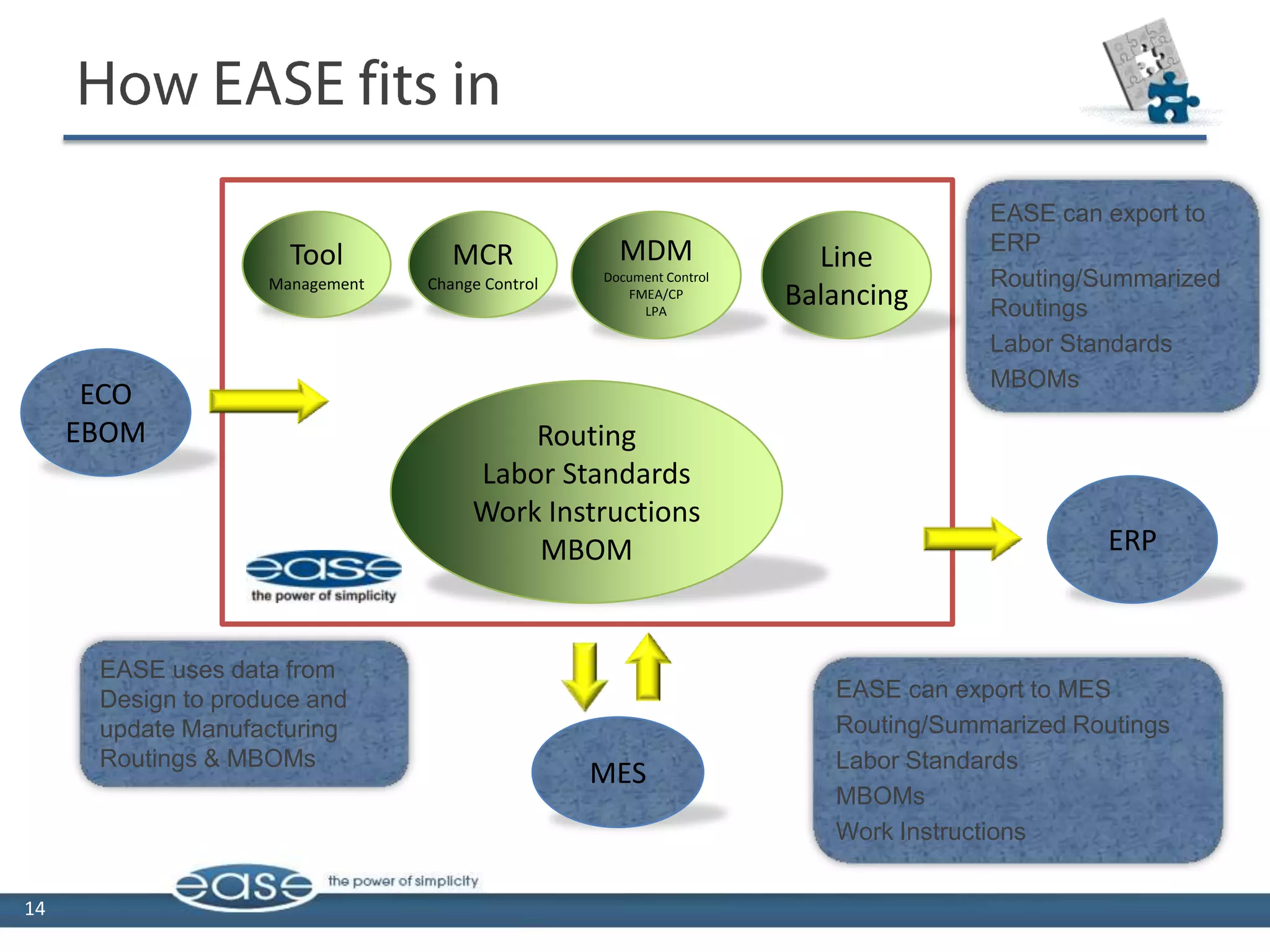

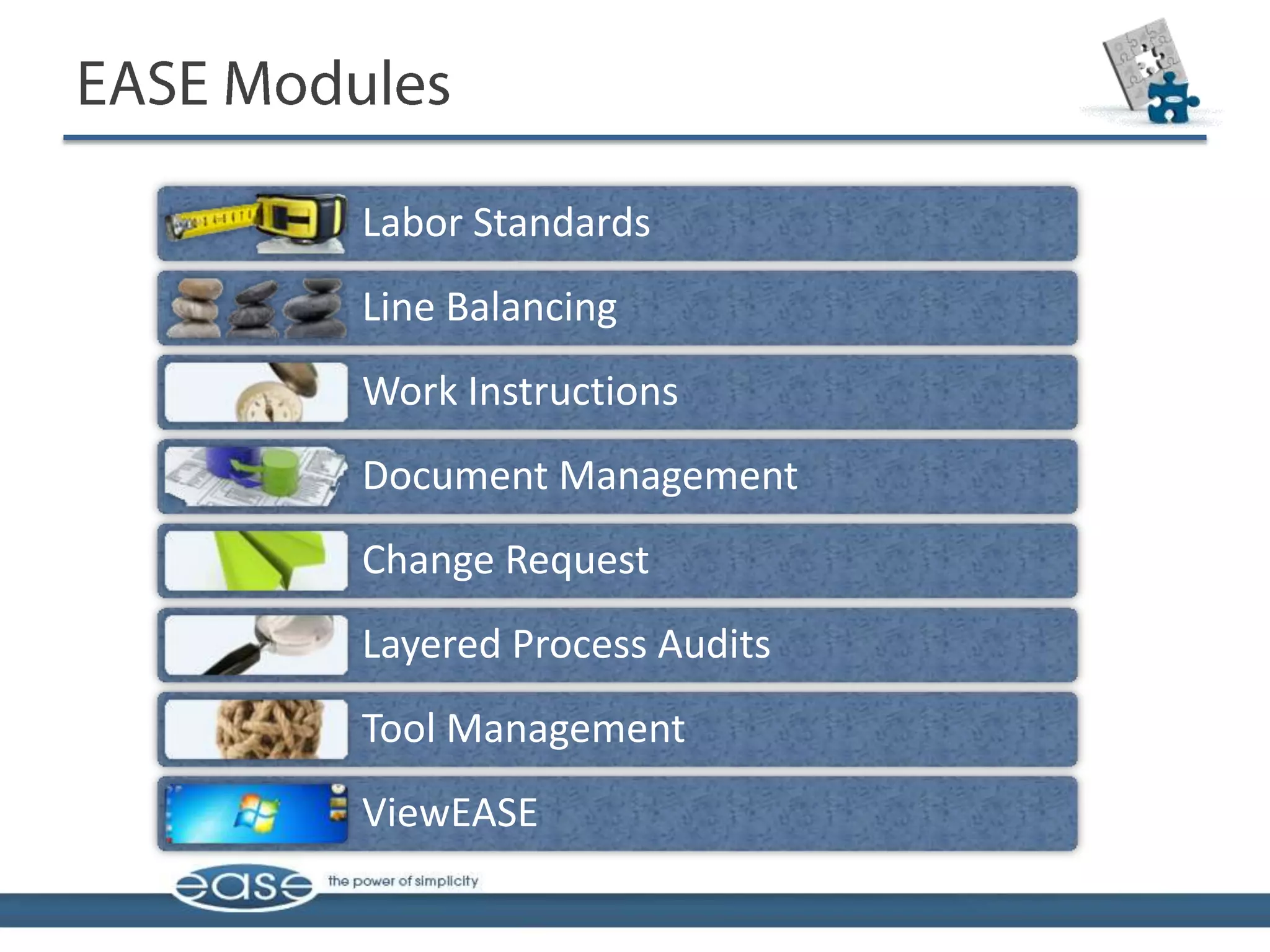

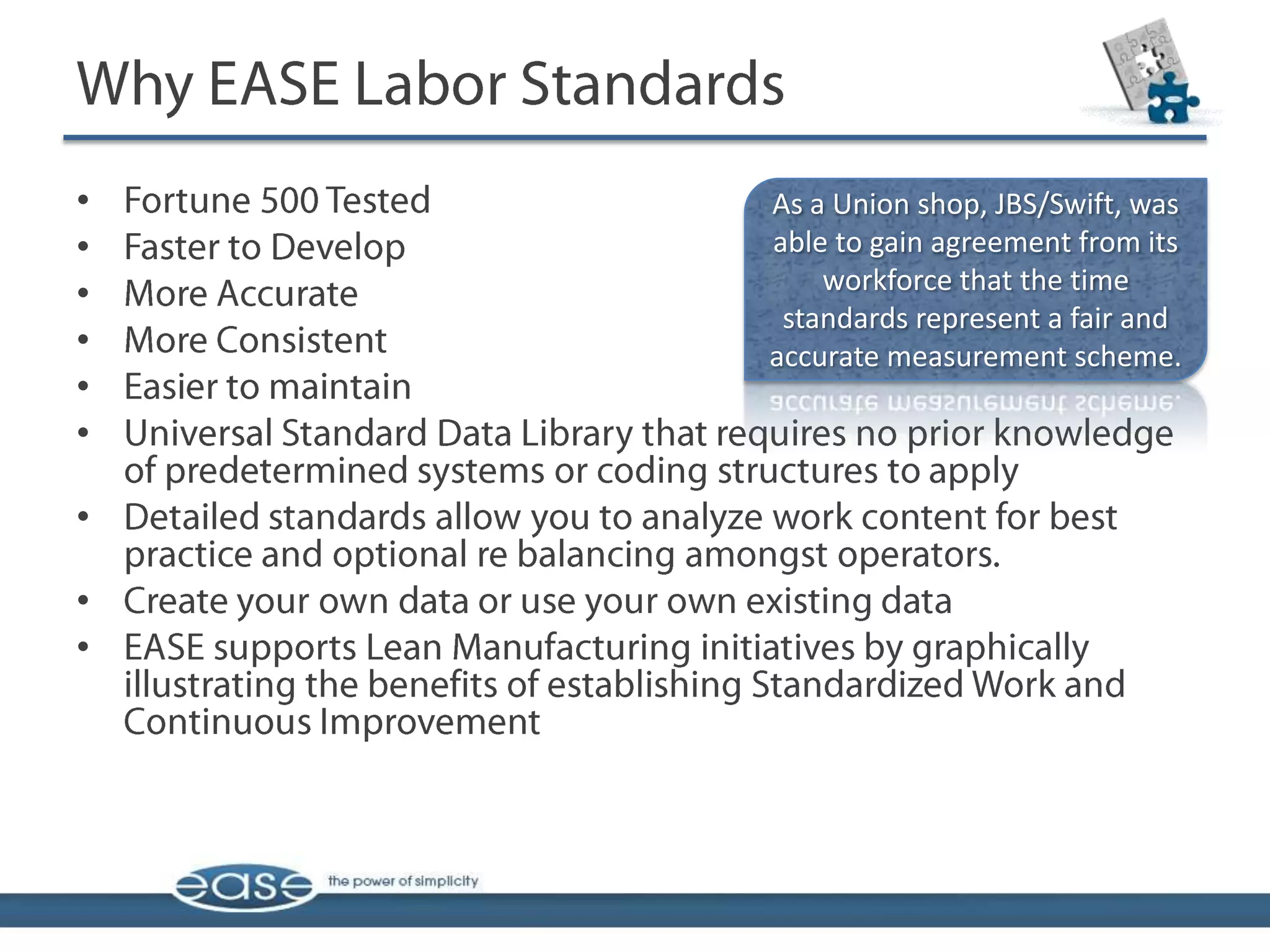

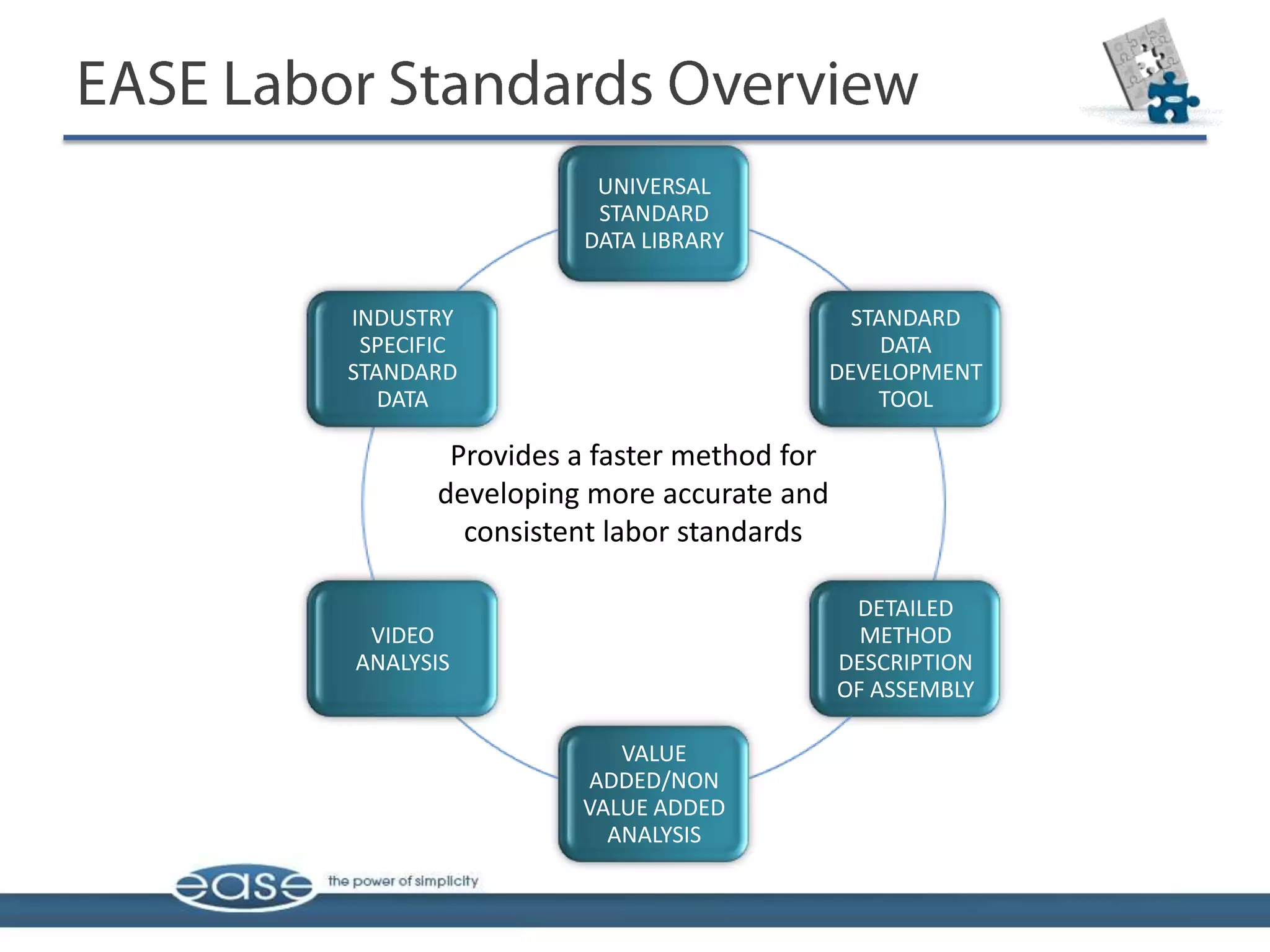

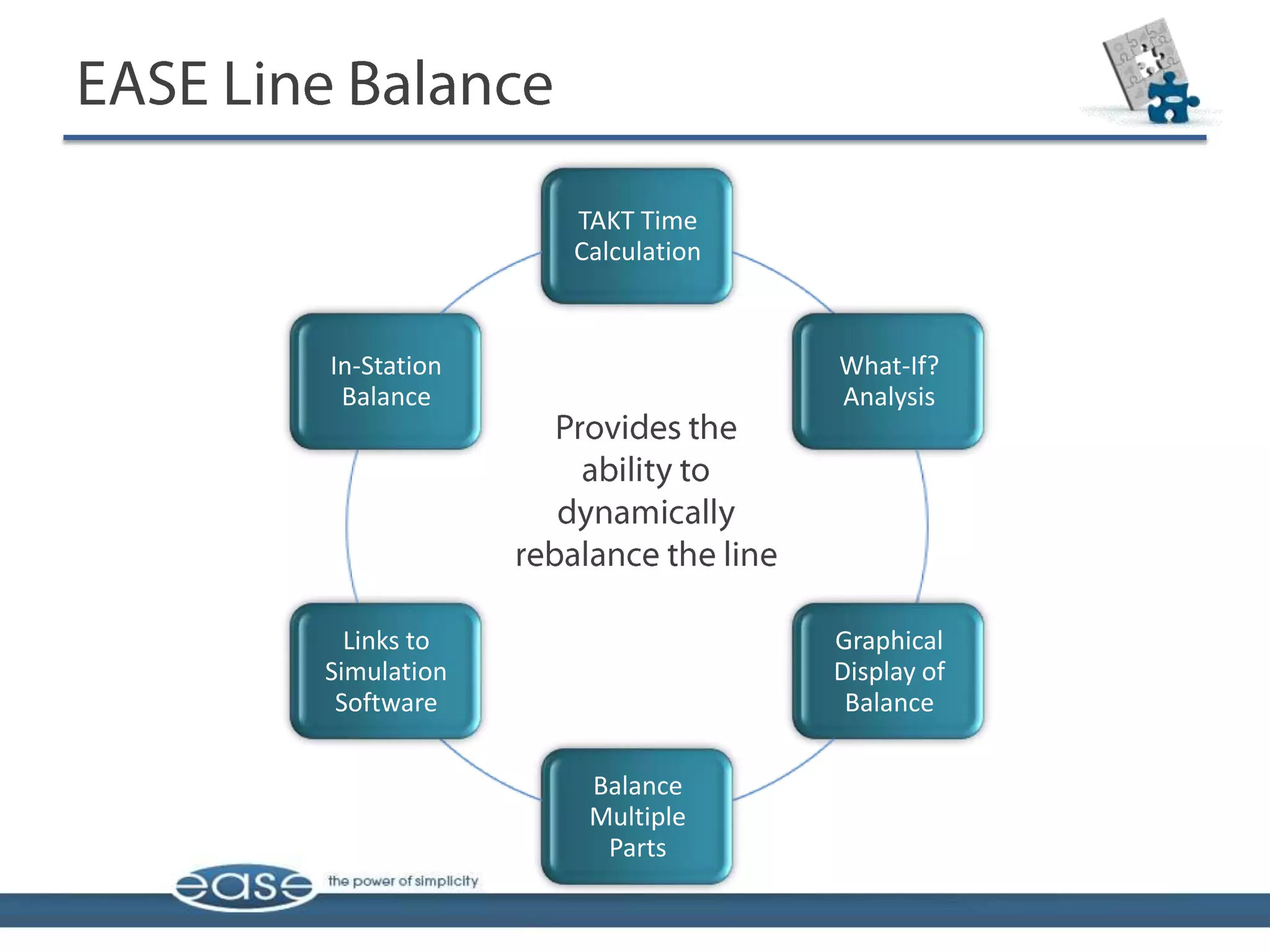

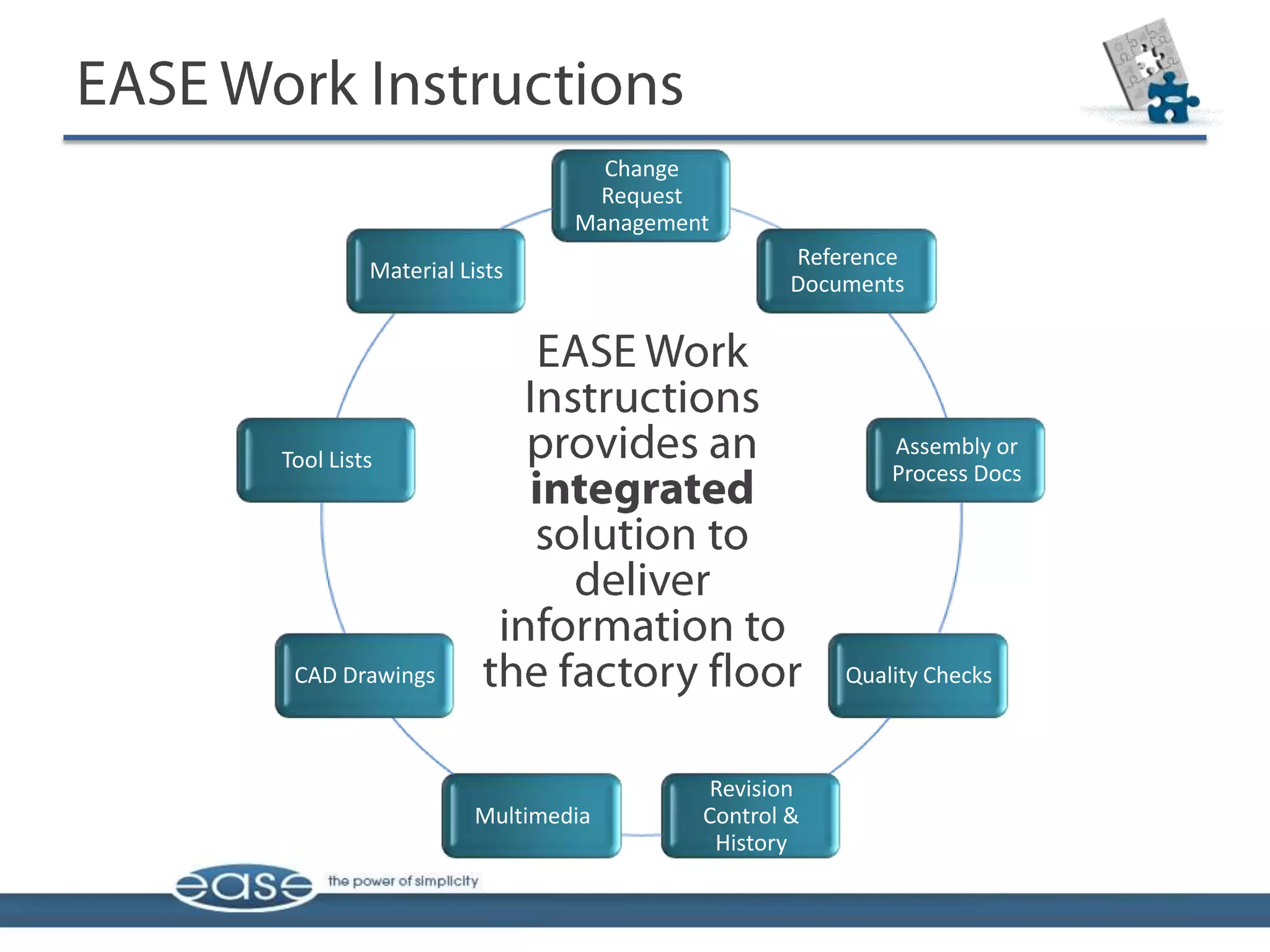

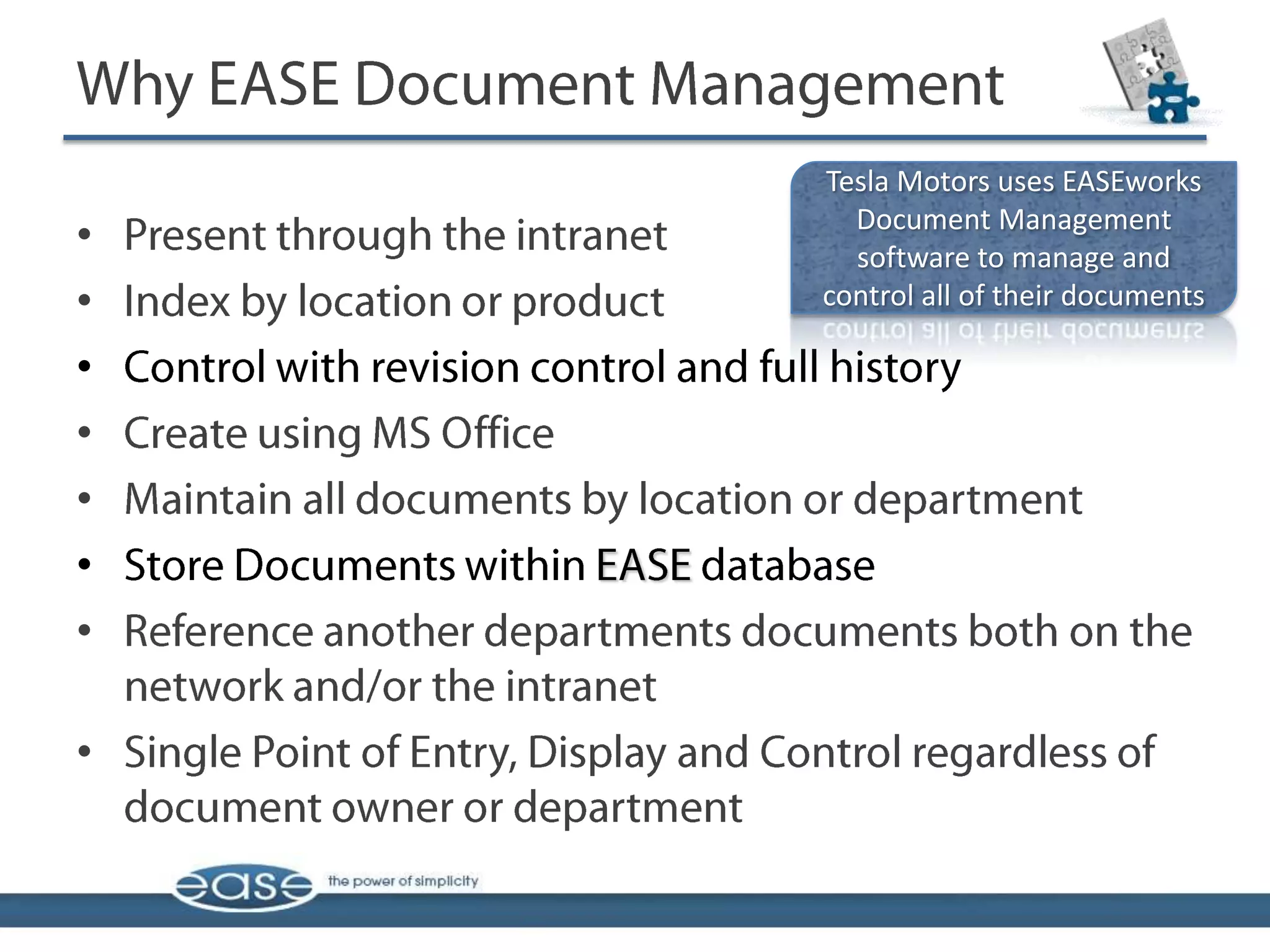

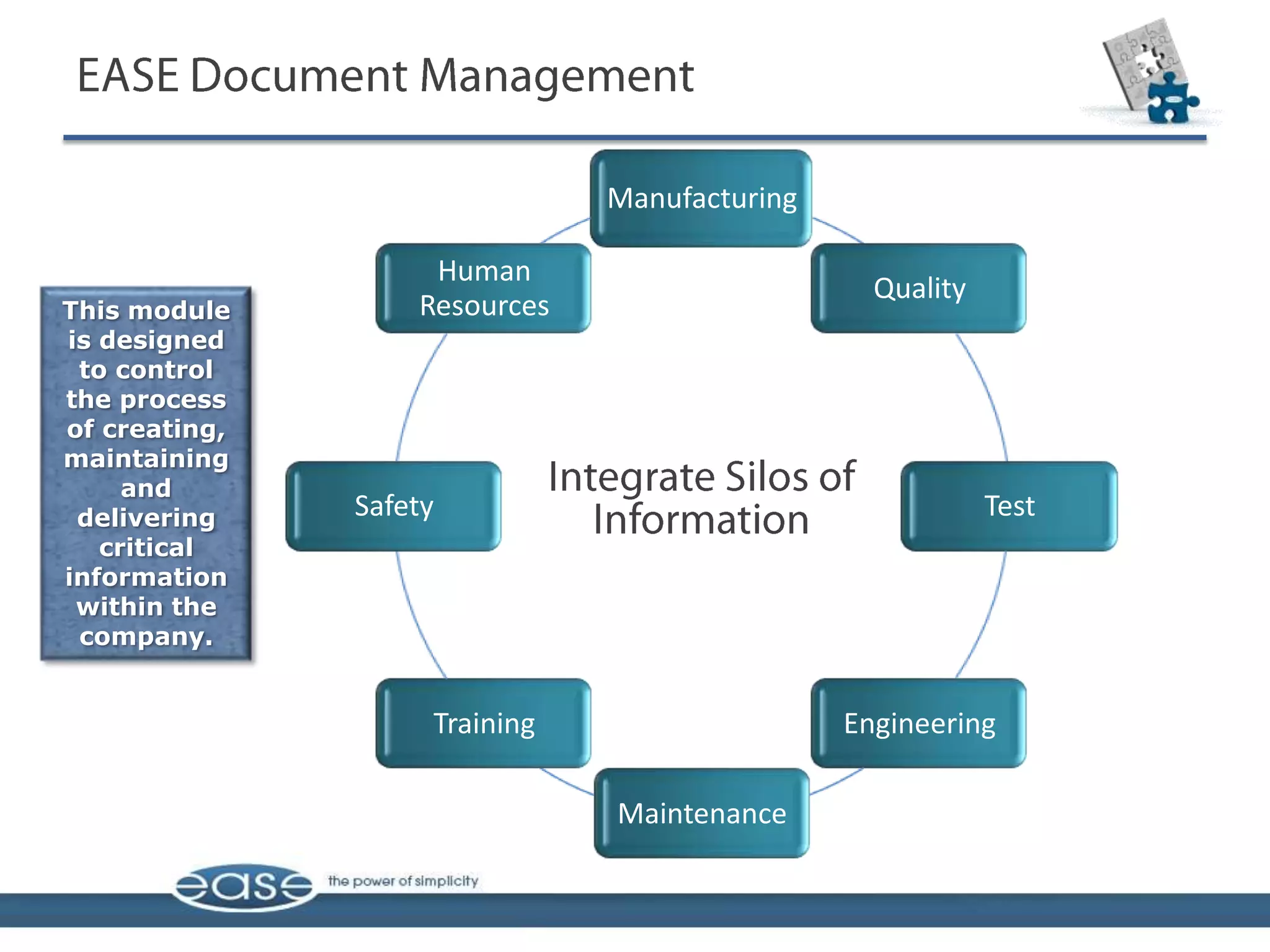

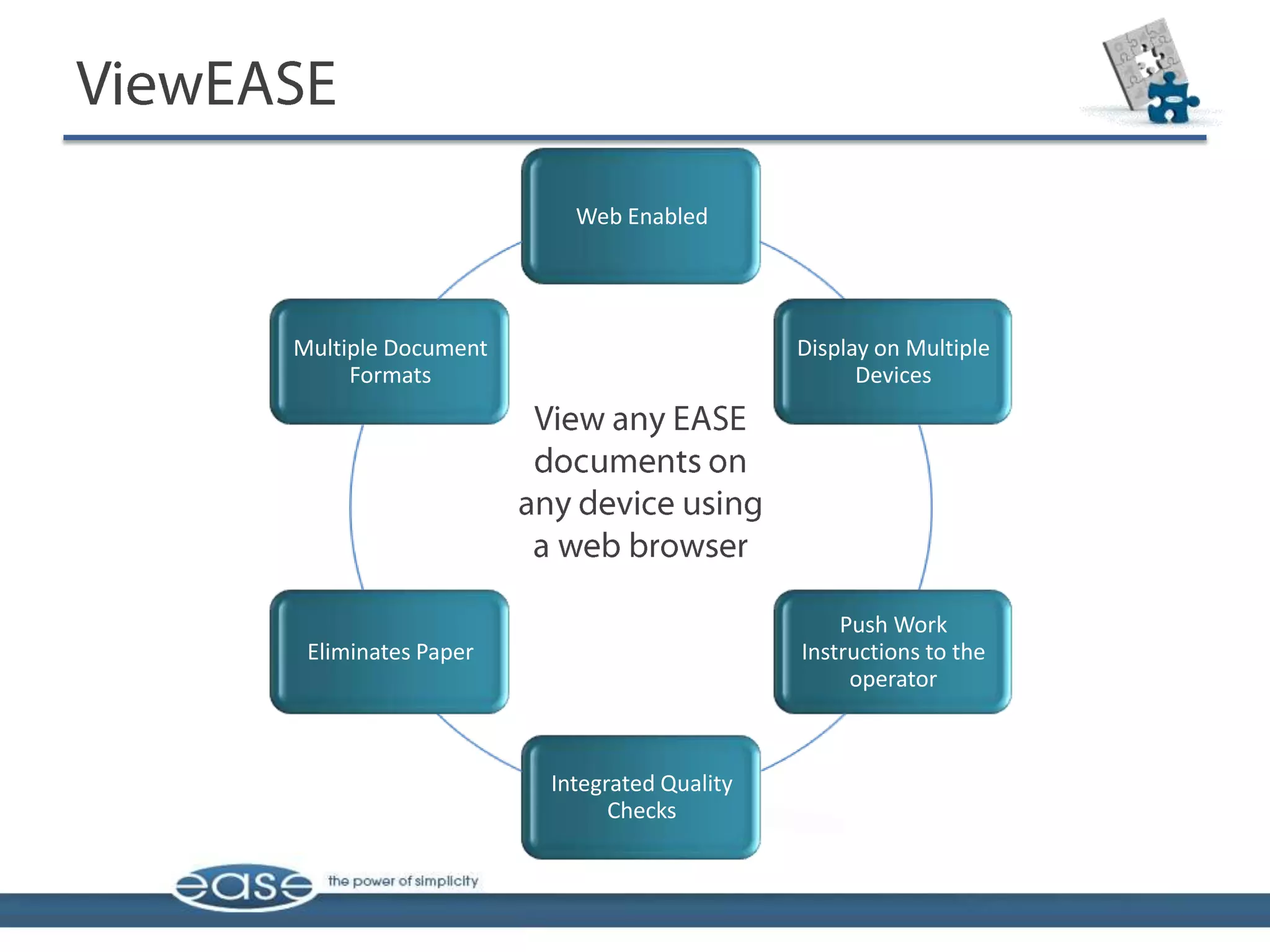

- EASE provides manufacturing design-to-production solutions including labor standards, line balancing, work instructions, and document management that support industries like agribusiness, retail, automotive, aerospace, and more.

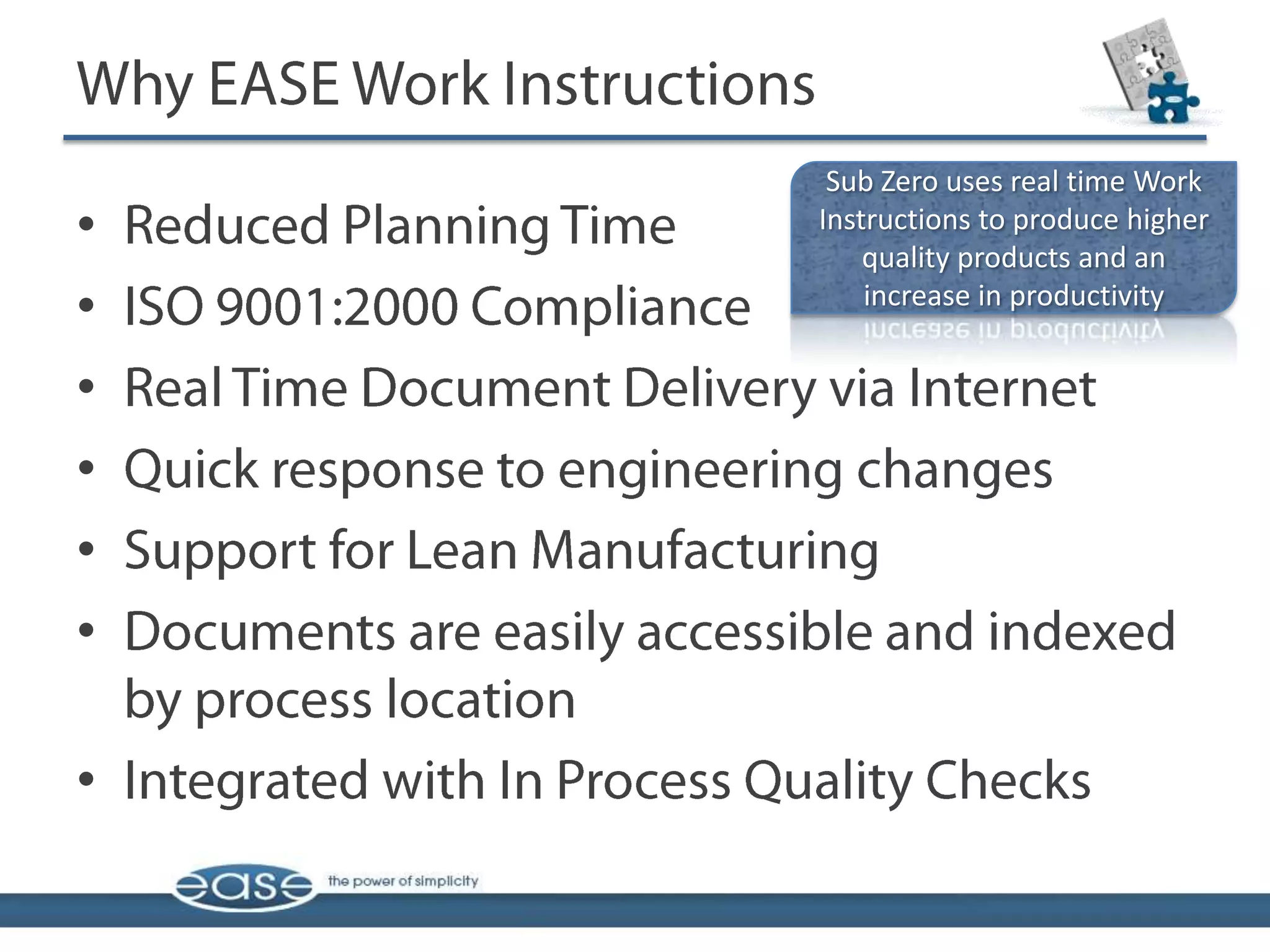

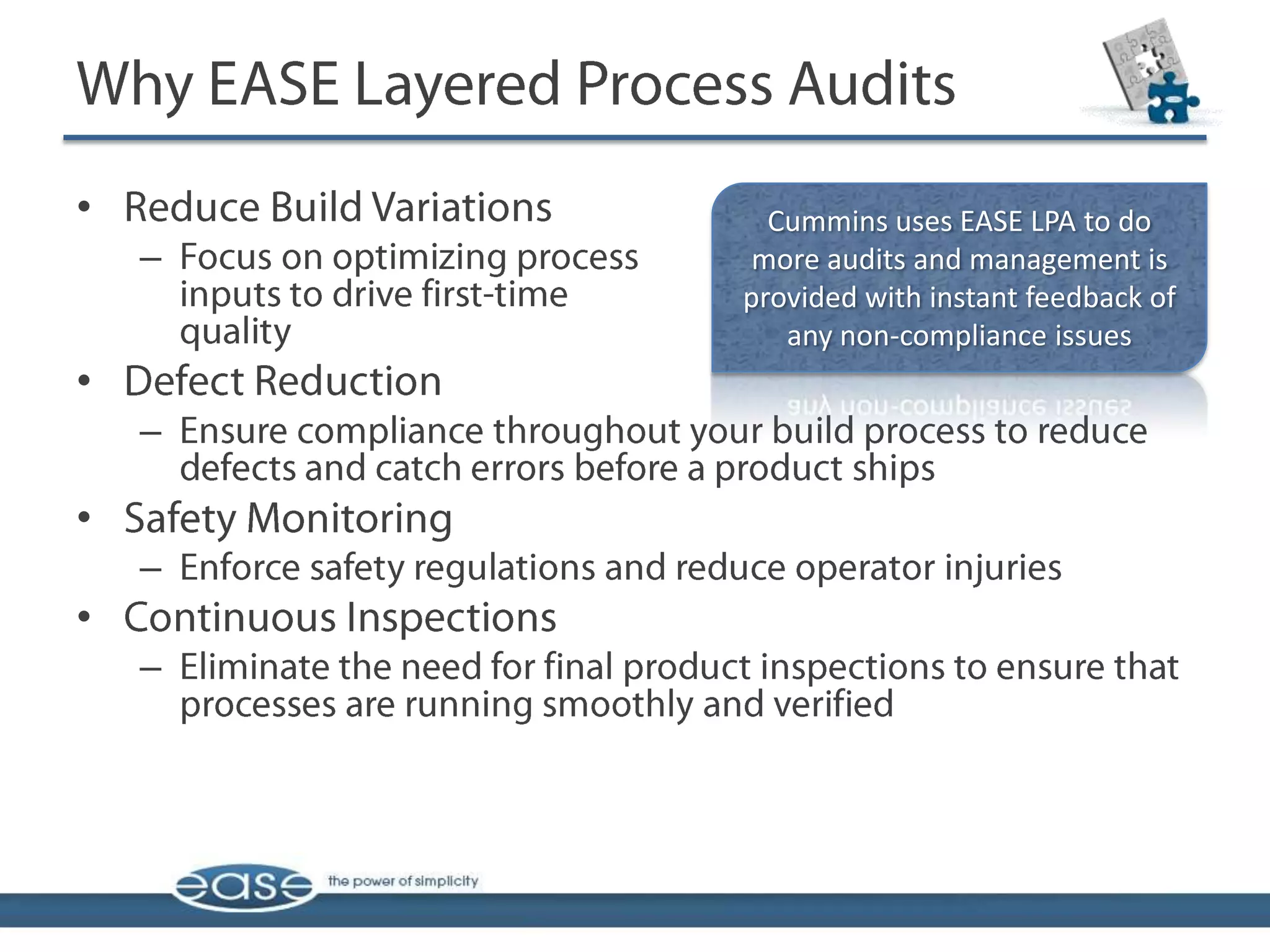

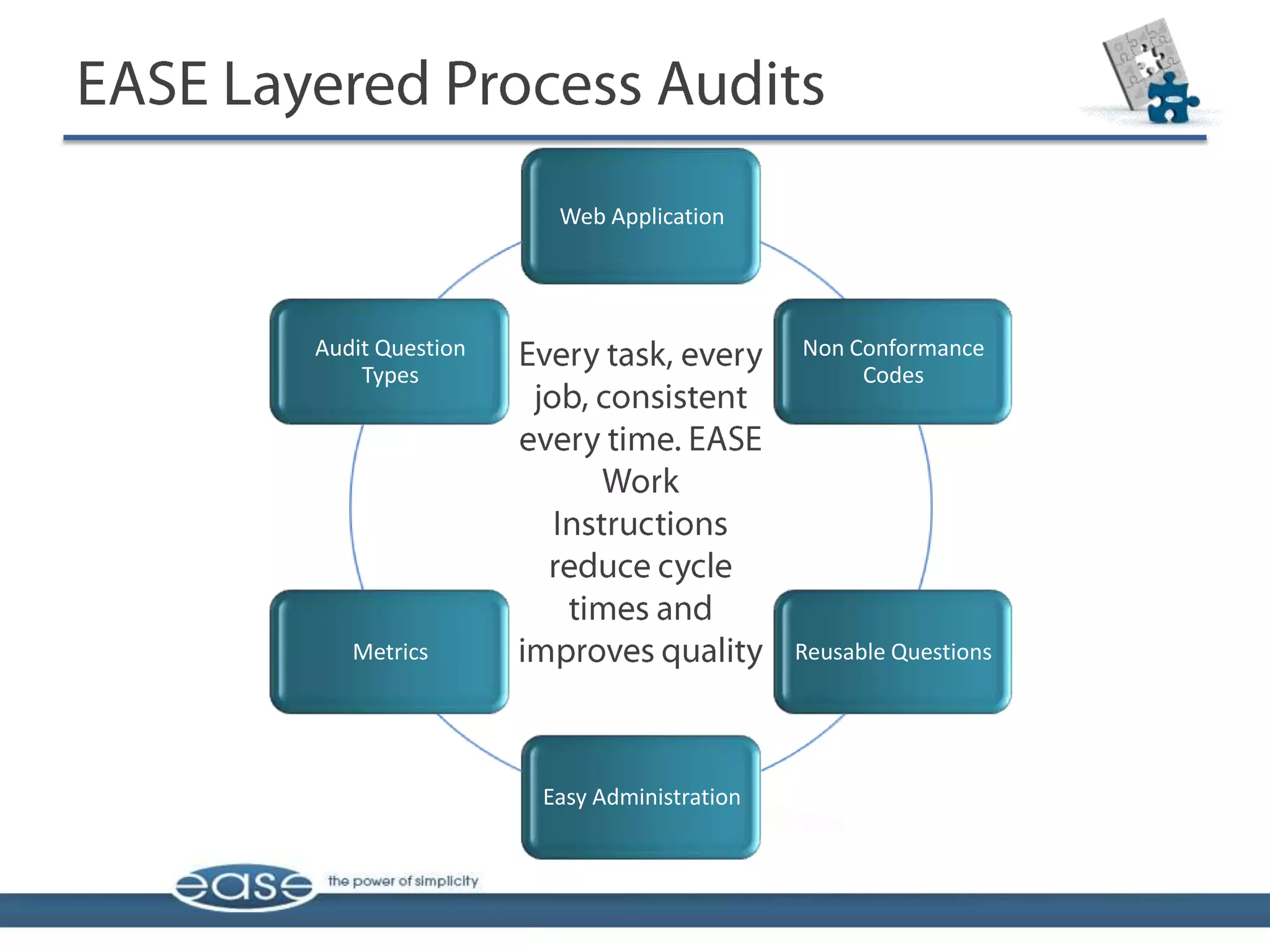

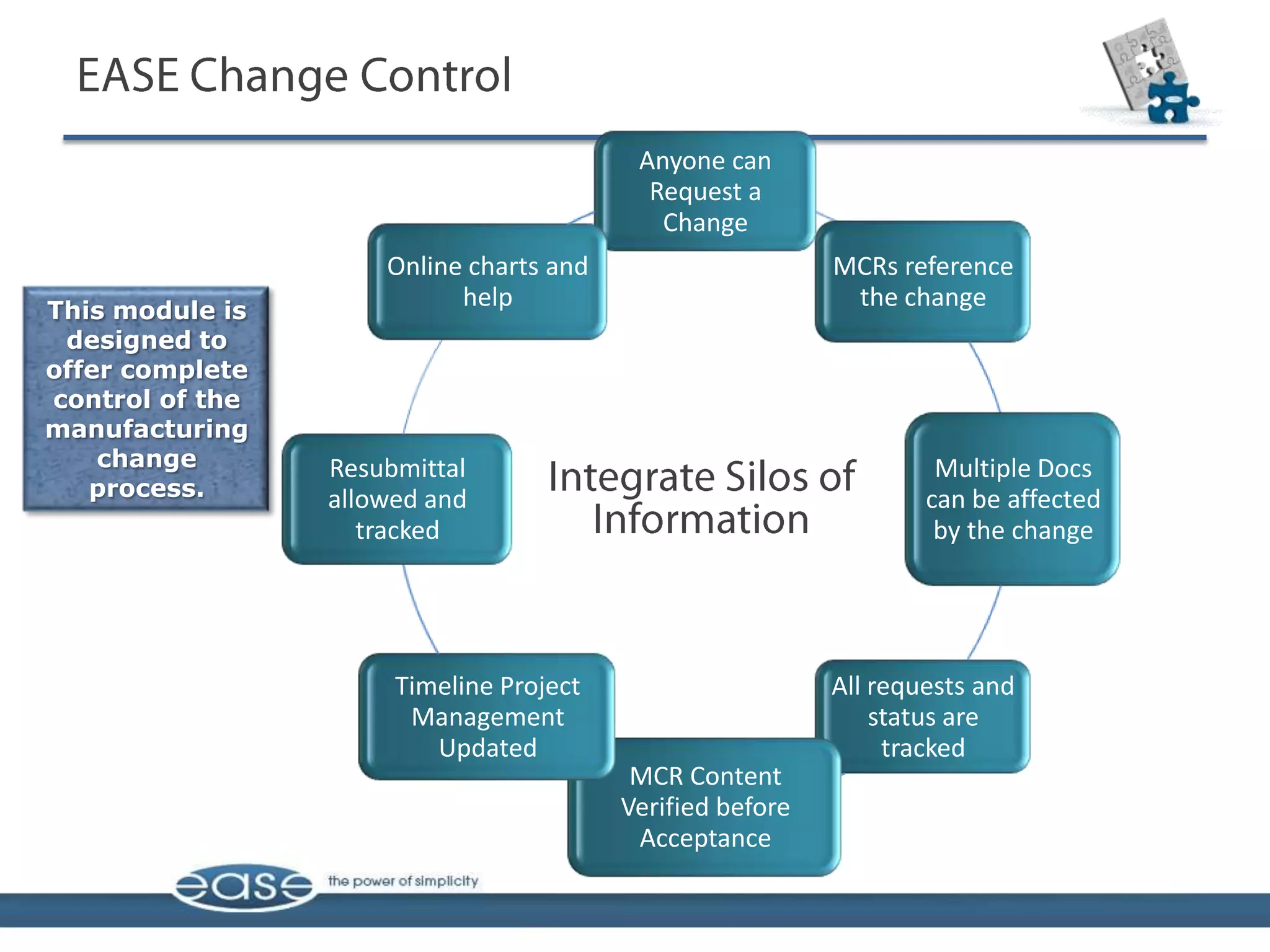

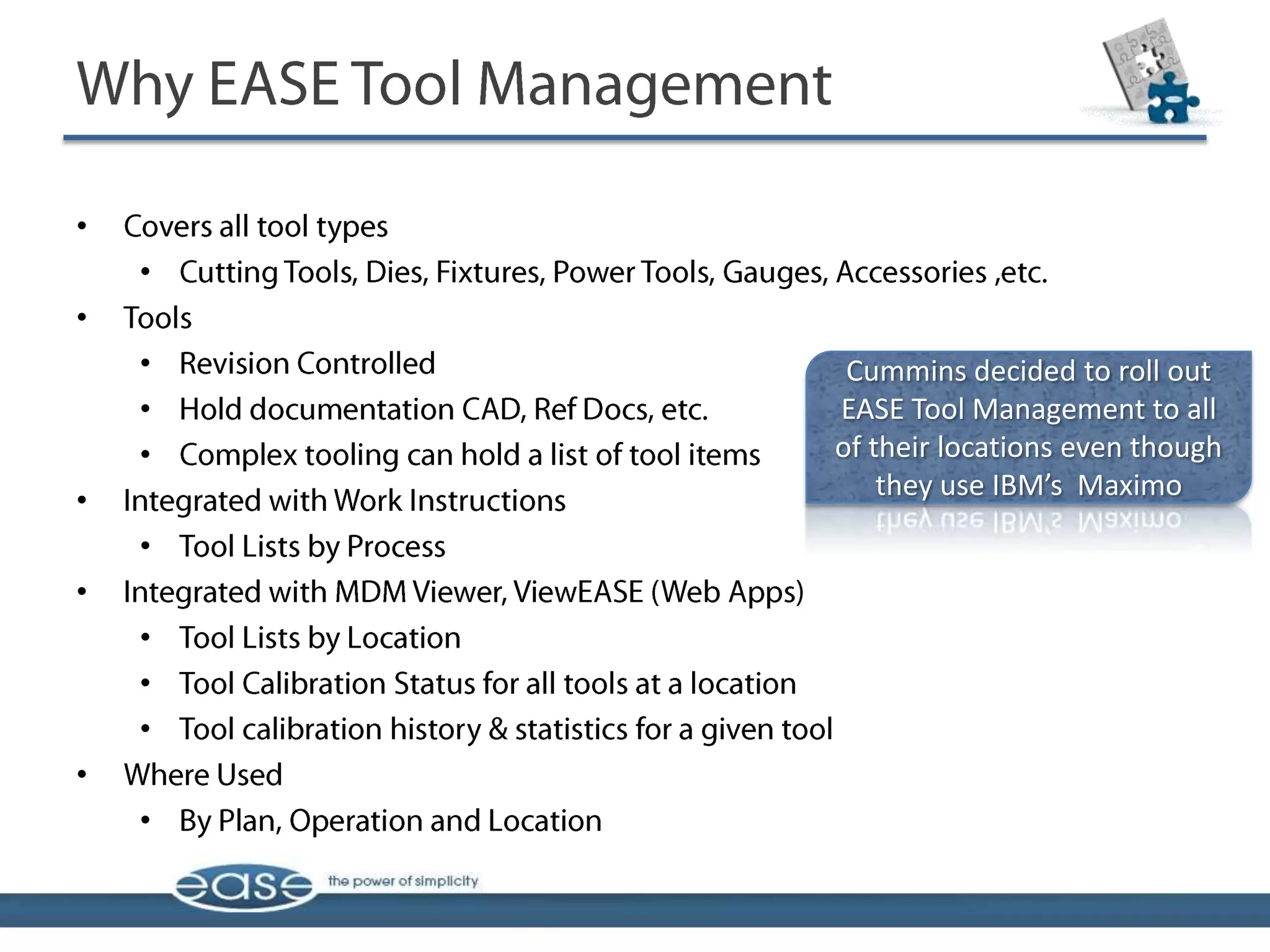

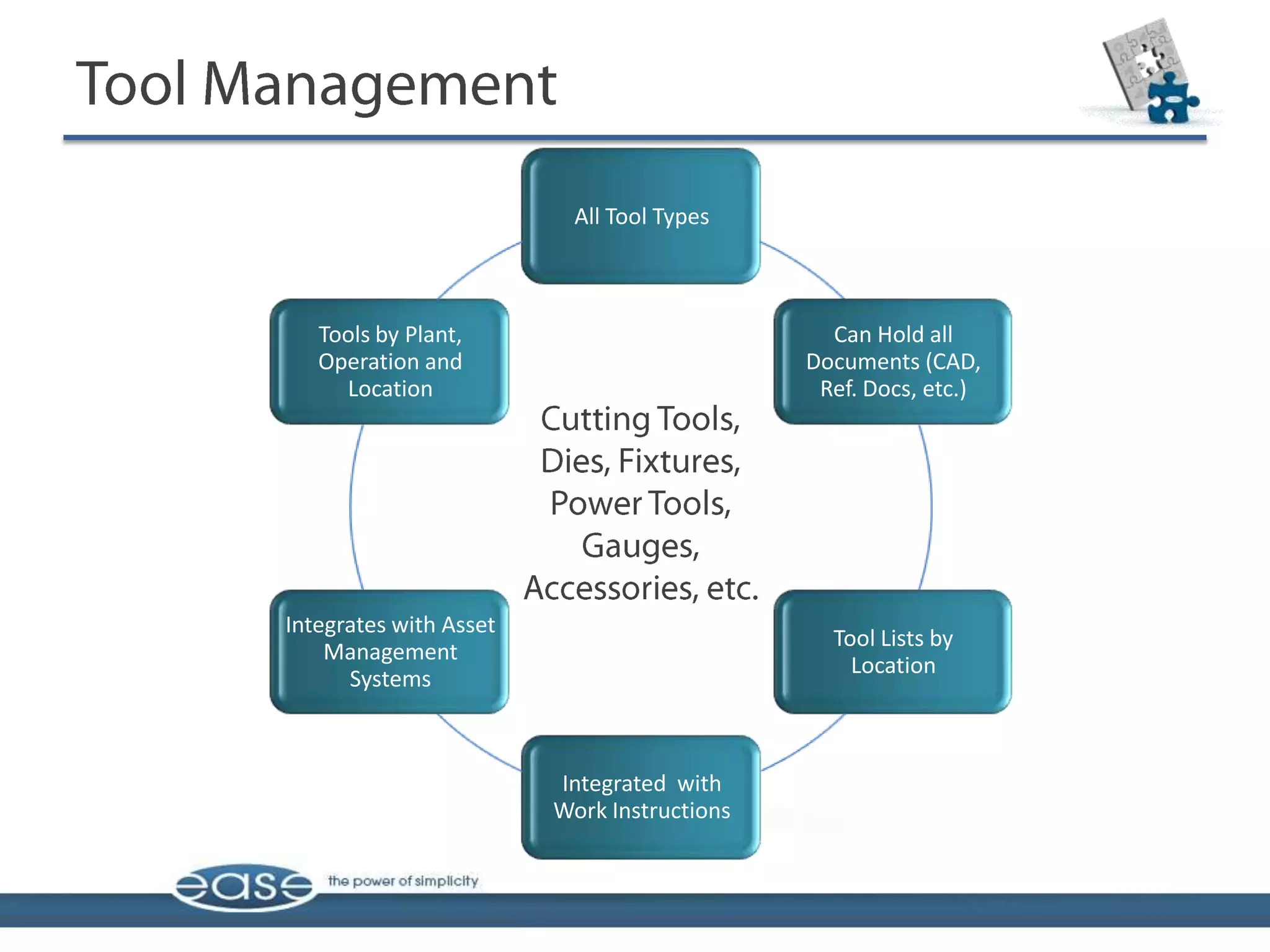

- Key capabilities include accurate labor standards, change control, process audits, and tool management.

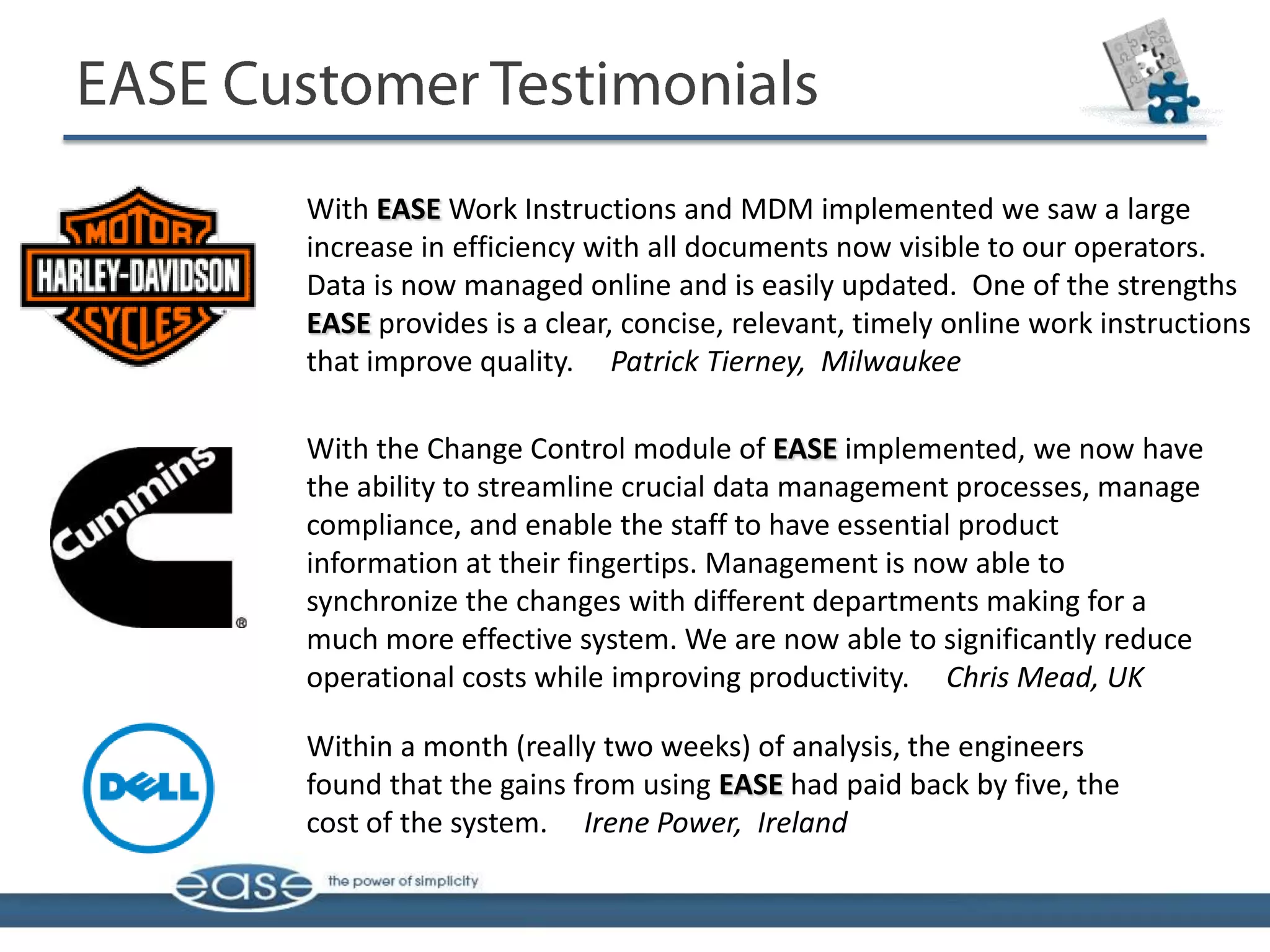

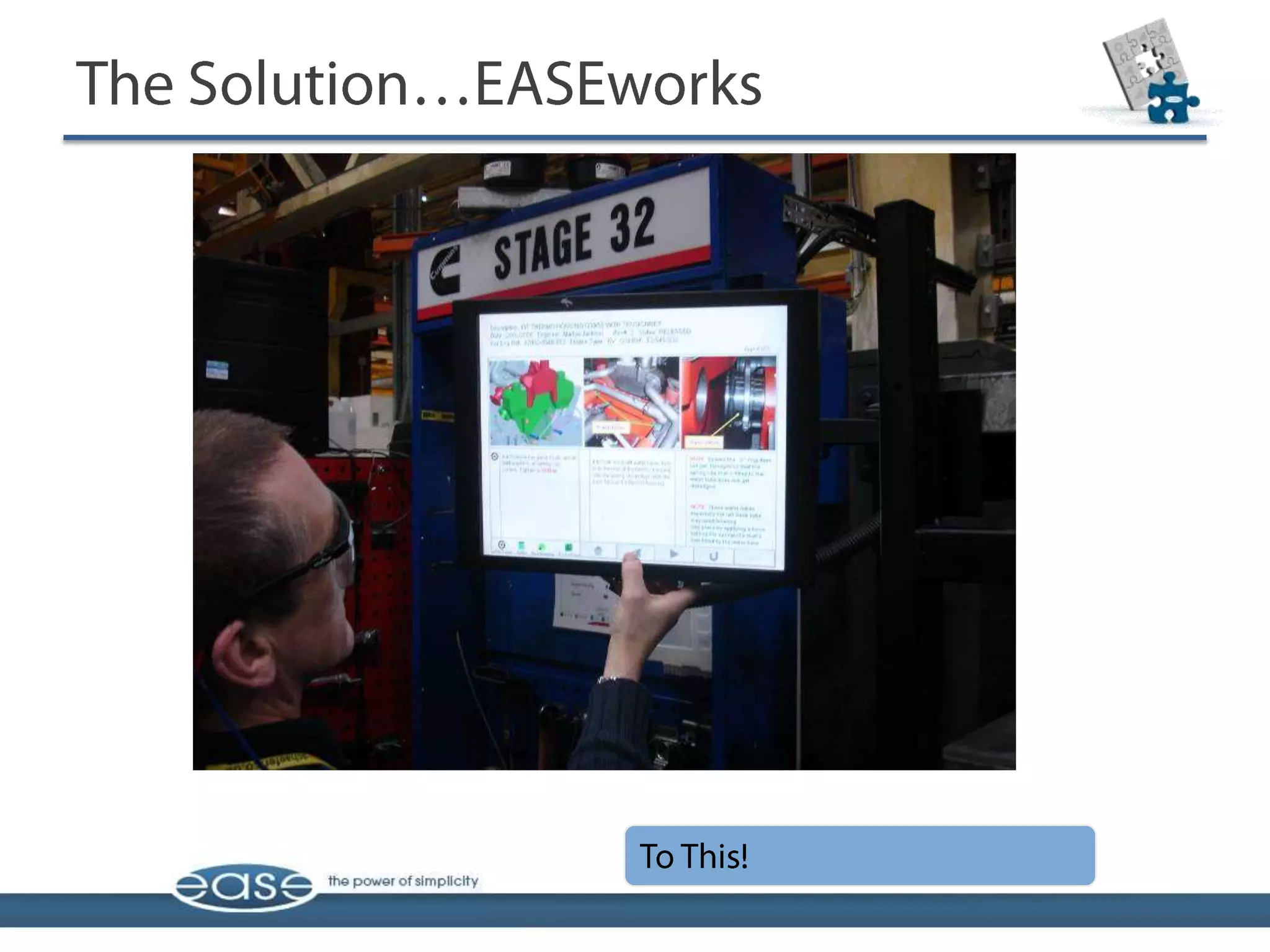

- Customers across various industries have experienced increased efficiency, productivity, and cost savings through the implementation of EASE solutions.