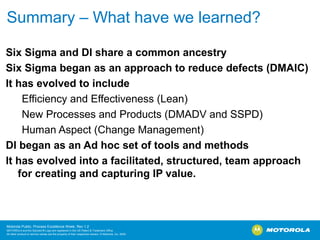

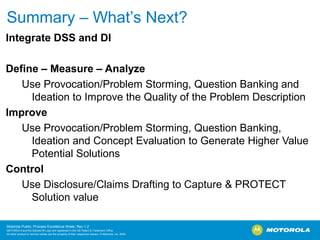

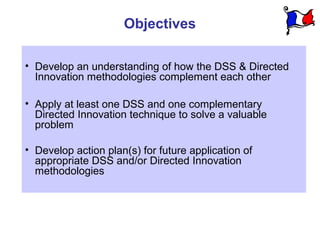

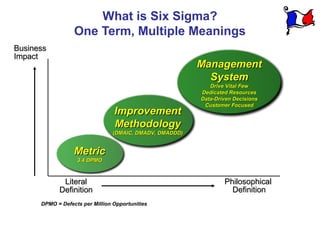

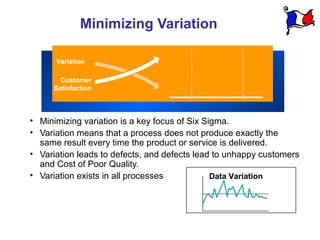

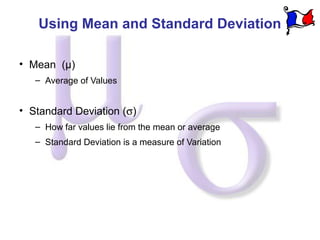

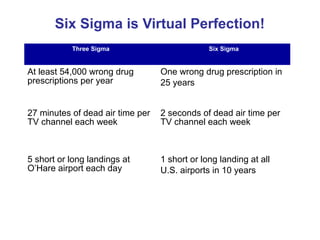

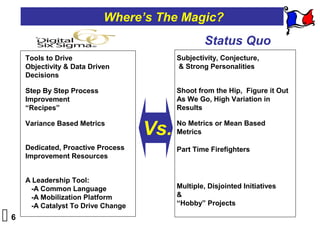

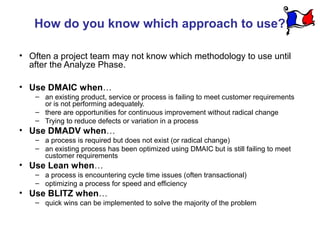

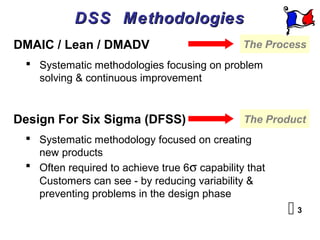

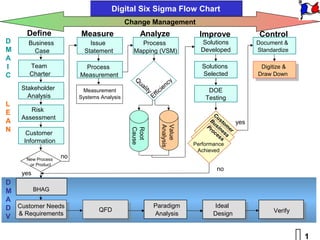

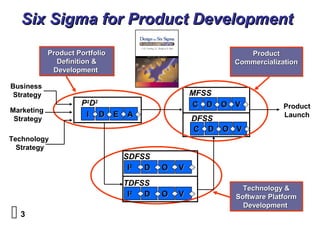

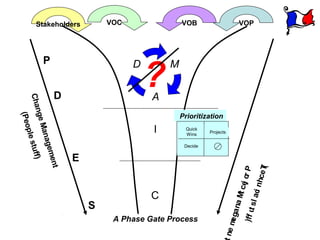

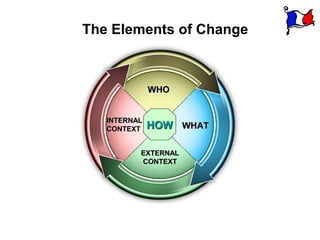

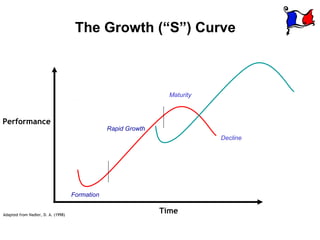

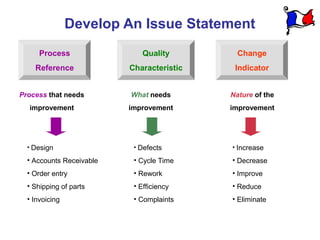

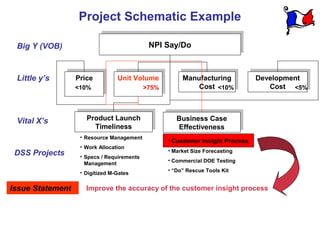

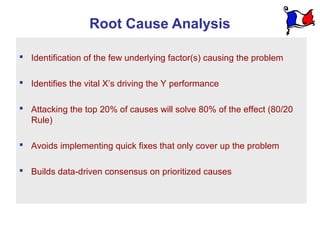

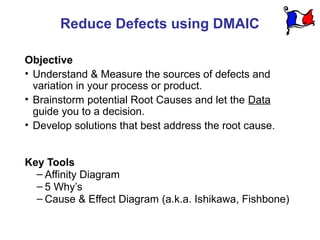

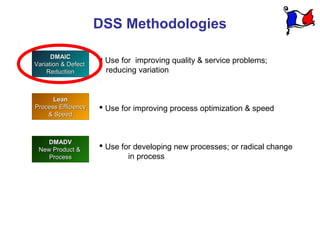

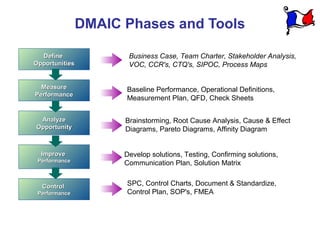

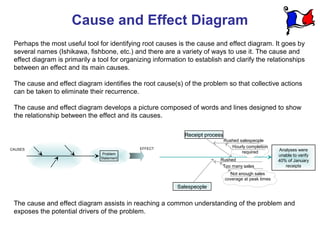

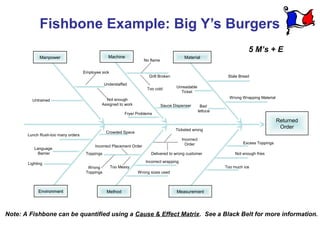

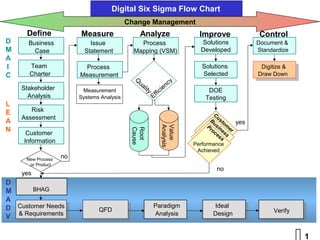

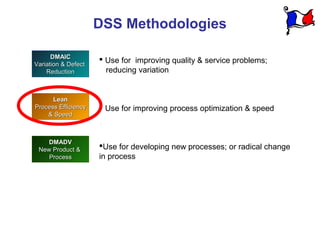

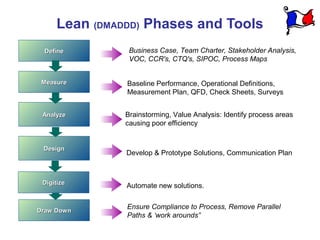

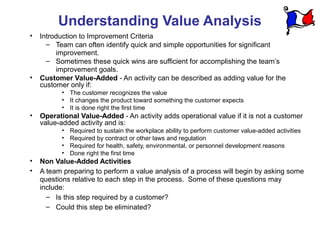

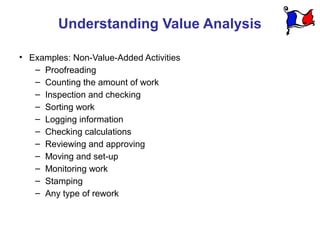

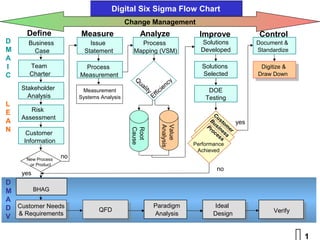

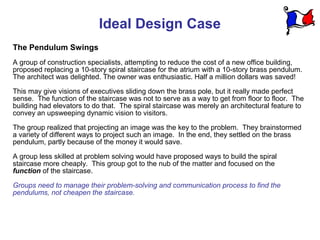

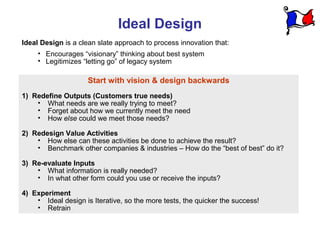

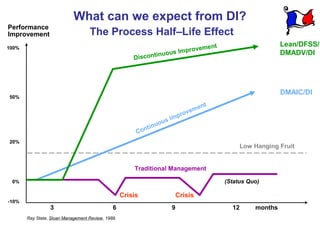

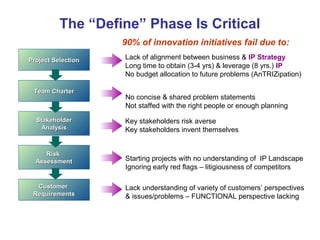

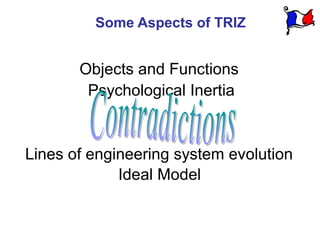

The document discusses how digital Six Sigma and directed innovation methodologies can complement each other to solve problems. It provides an overview of key Six Sigma concepts like the DMAIC process, variation, and root cause analysis tools. The presentation also examines factors that can cause Six Sigma projects to fail if not properly addressed, such as lack of stakeholder commitment or an unclear problem statement.

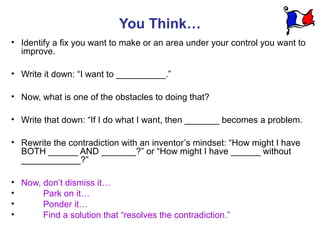

![“Even though one was correct at each stage, the situation may still have to be

restructured to proceed.” Edward de Bono [http://www.edwdebono.com/]

Key Insight #2:

Be willing to rearrange

what you know

(overcome psychological inertia!)

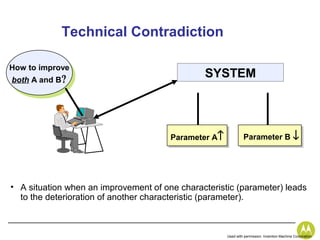

contradictions](https://image.slidesharecdn.com/ldssvsdiupdatedforwic2012-13542743753129-phpapp01-121130052149-phpapp02/85/Digital-Six-Sigma-vs-Directed-Innovation-95-320.jpg)

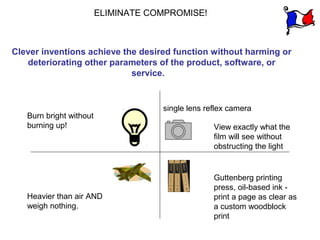

![400,000 Inventions Studied by Altshuller –

The Most Clever Solved Contradictions

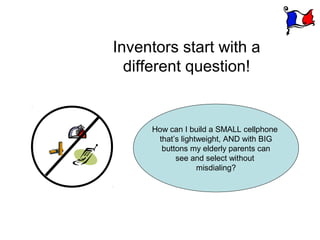

Key Insight #3:

If you find yourself trading off features, reframe

your desire into, “I want BOTH [feature 1] AND

[feature 2].”

Then stay in this

creative space!](https://image.slidesharecdn.com/ldssvsdiupdatedforwic2012-13542743753129-phpapp01-121130052149-phpapp02/85/Digital-Six-Sigma-vs-Directed-Innovation-101-320.jpg)