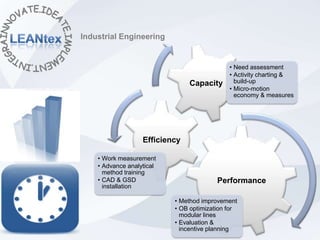

Innovate.ideate.implement.integrate is a management consultancy specializing in apparel operations, focusing on manufacturing facility setup, production enhancement, and lean manufacturing implementations. The firm aims to improve productivity, quality, and efficiency through innovative solutions and rigorous training, enhancing clients' capabilities in various operational areas. Their services encompass everything from industrial engineering and capacity building to sustainable practices and quality management systems.