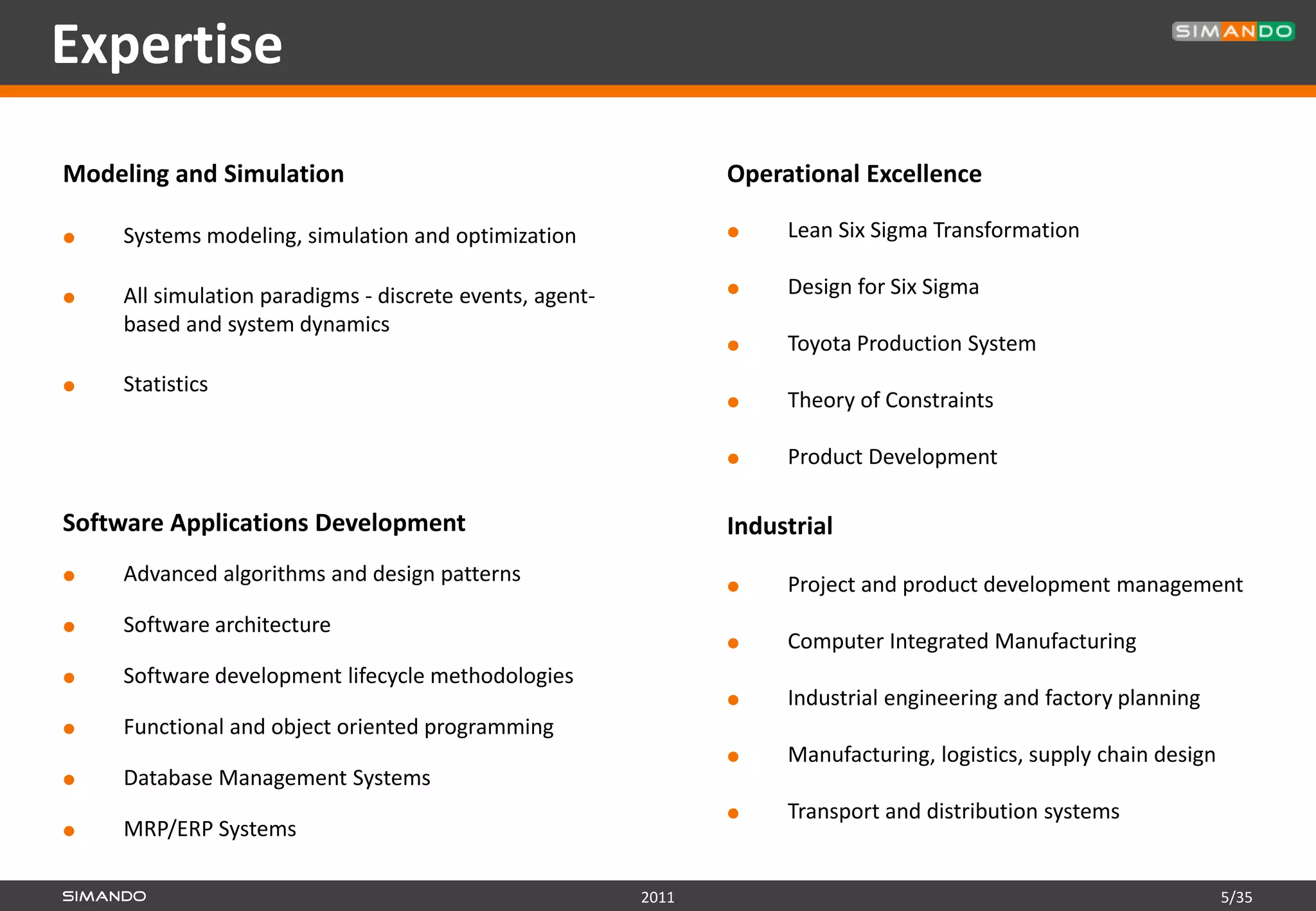

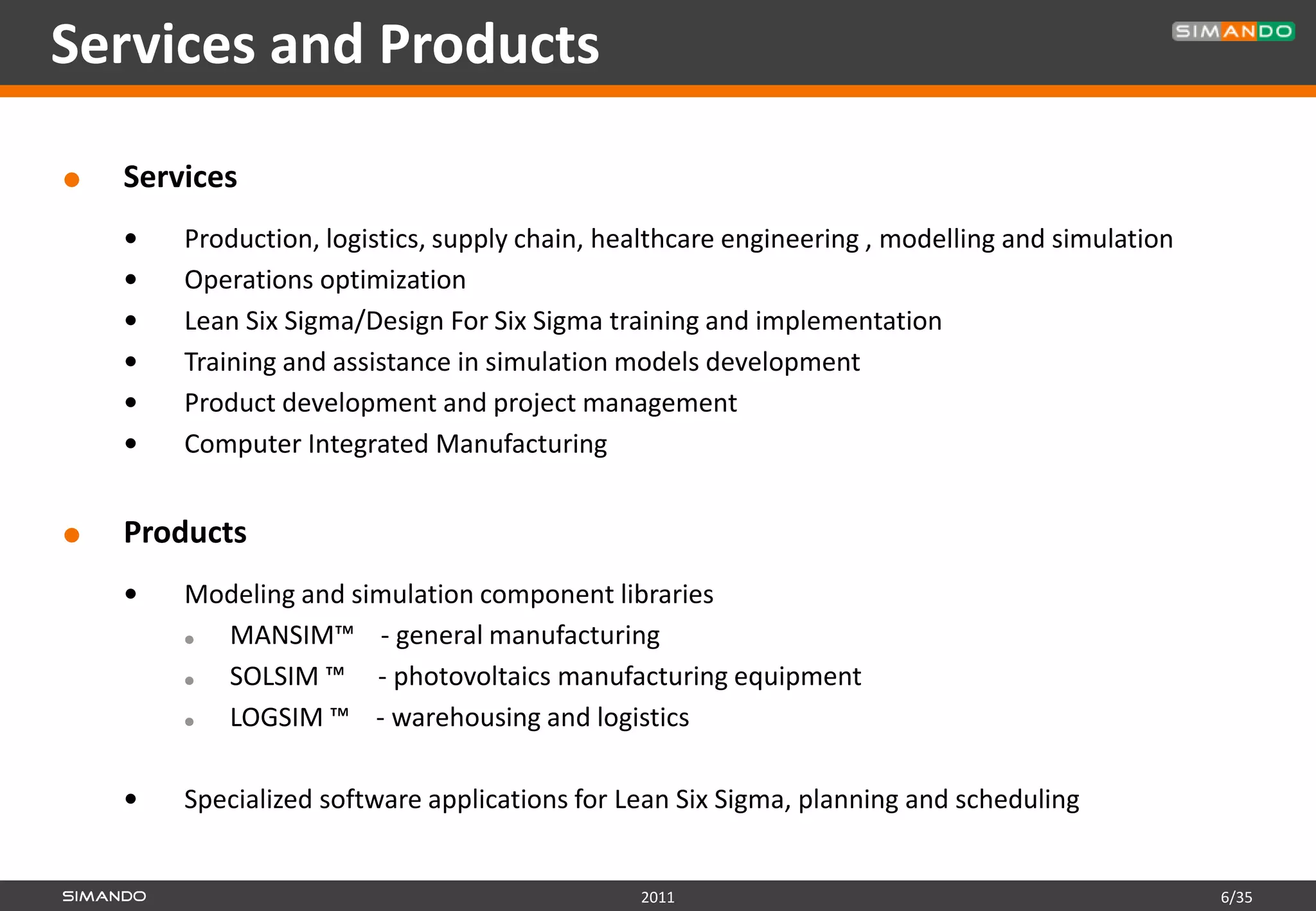

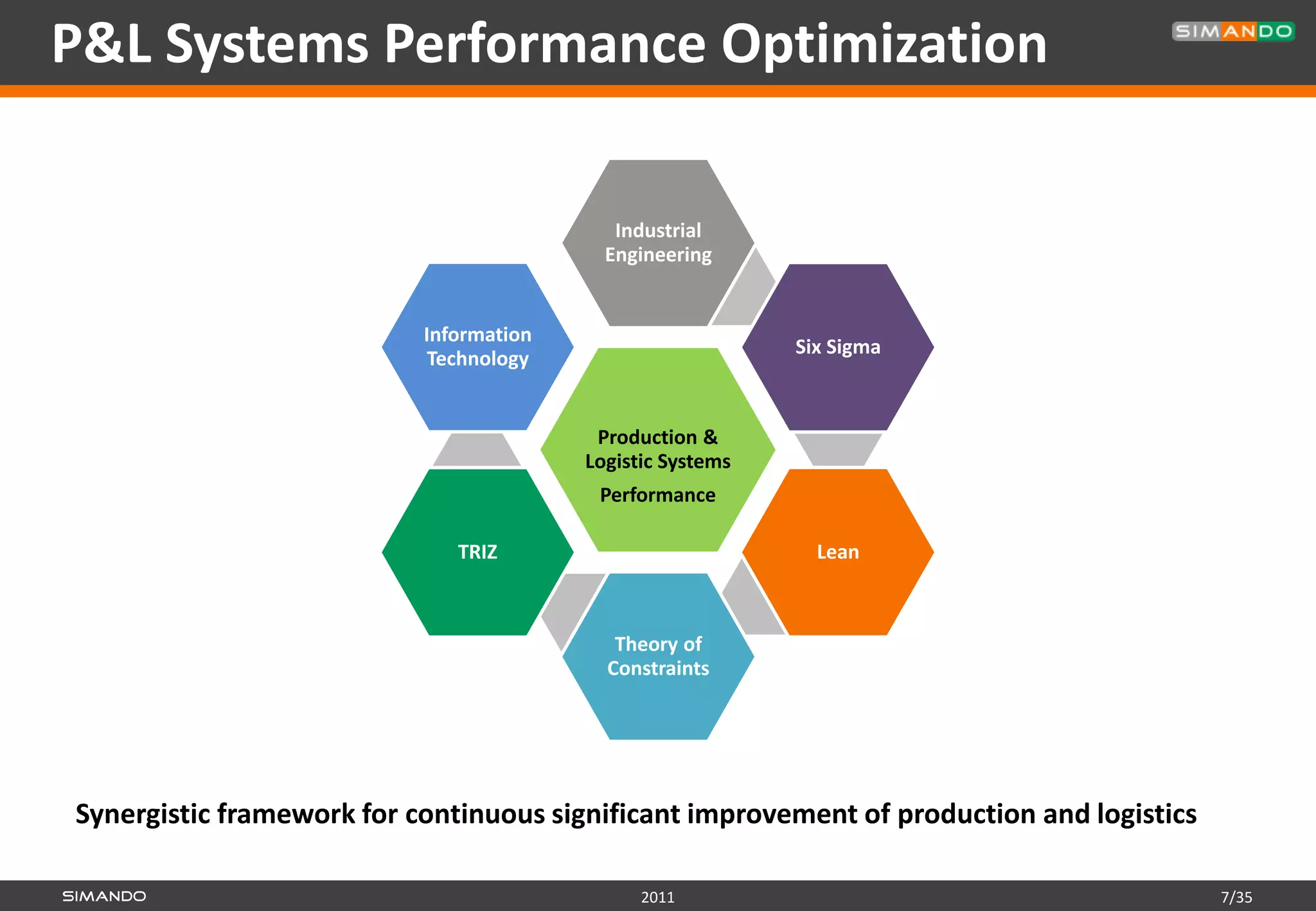

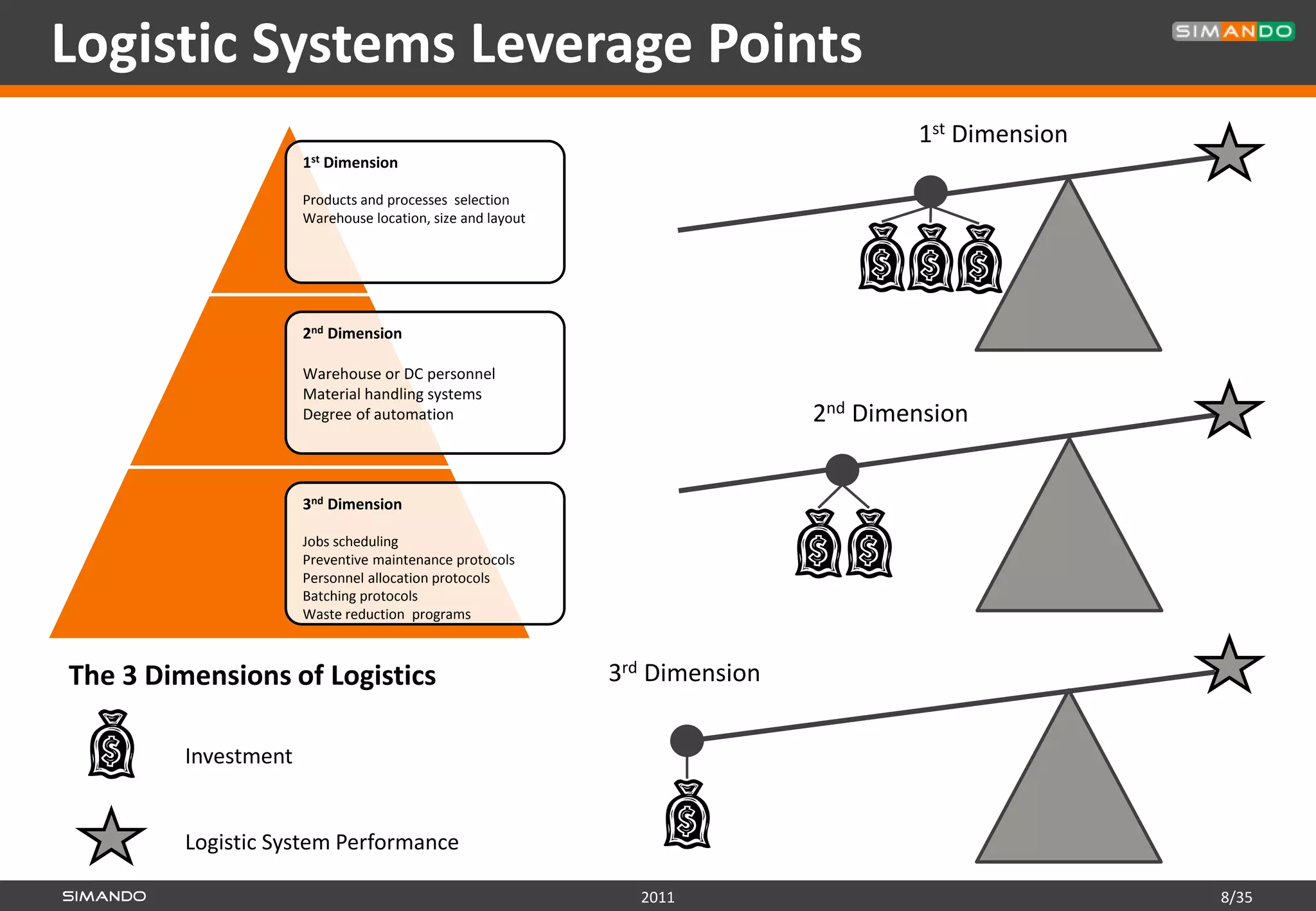

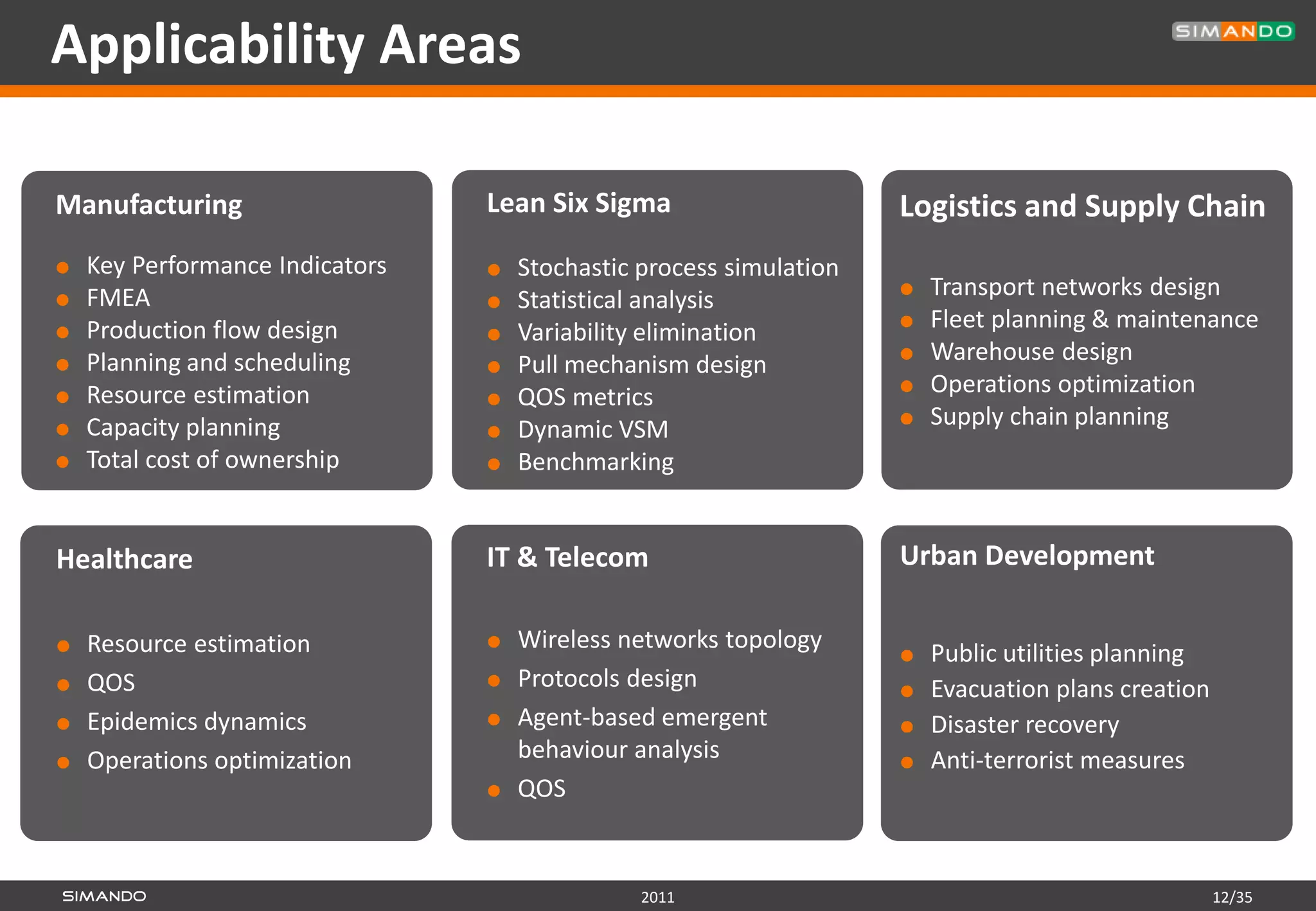

SIMANDO is a global management consulting firm specializing in decision support systems and operational excellence. They partner with clients to address challenges and develop optimized solutions using innovative technology, systems thinking, and a focus on operational excellence. SIMANDO provides customized simulation modeling, optimization, and Lean Six Sigma services to help clients achieve sustainable competitive advantages through improved operations and responsiveness. They are a privately-owned company based in Timisoara, Romania that was founded in 2009.