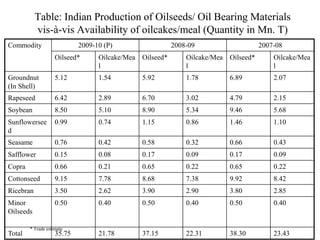

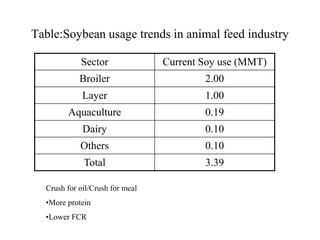

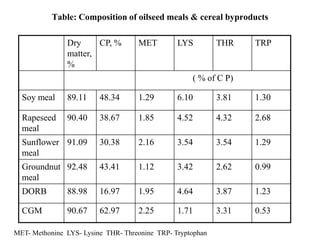

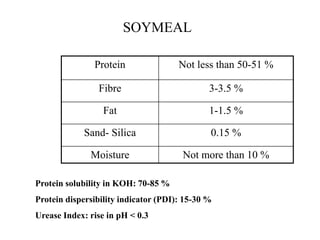

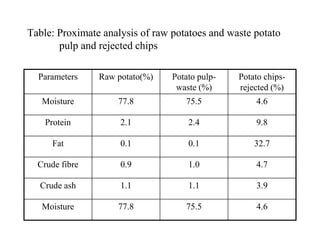

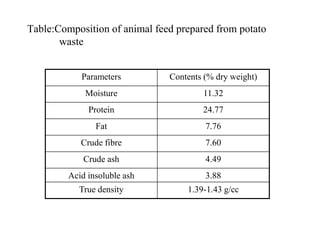

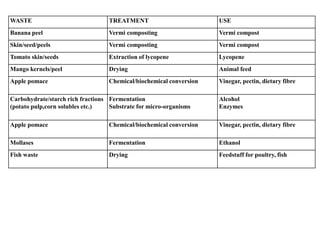

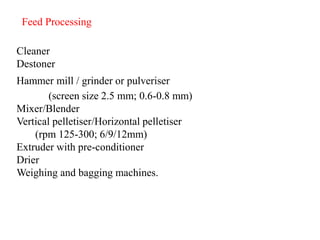

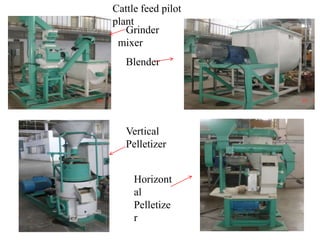

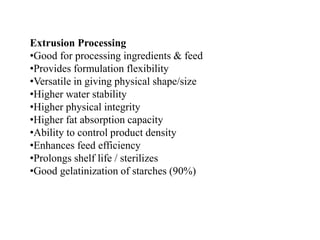

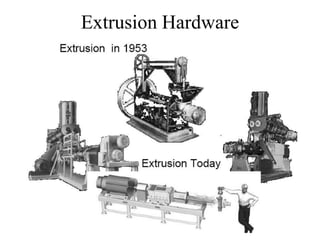

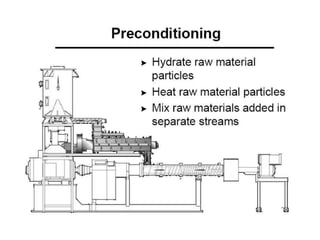

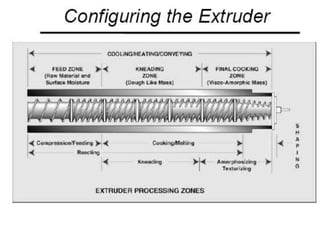

This document discusses the utilization of co-products from oilseed processing and potato waste in animal feed. It provides information on feed production in India, composition and use of various oilseed meals and co-products in feed. Potato waste and rejected potato chips can be used to produce nutritious animal feed pellets after processing. The document also outlines the associations involved in the feed industry and the various steps in processing feed from raw materials.

![Production in India in 2009 (Source: FAO)

[Meat ‘000 tonnes (carcass weight equivalent); Milk: million

tonnes ]

Bovine meat 2,848

Ovine meat 800

Pig meat 500

Poultry meat 2,624

Milk & milk products 112.3](https://image.slidesharecdn.com/animalfeeddrdhingra-170801164633/85/Animal-feed-constituents-5-320.jpg)